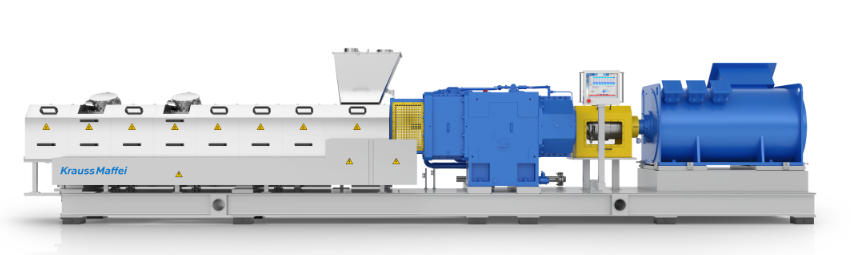

ZE 120 GP Twin-Screw Extruder Officially Launched, Achieving Excellence in the Industry

With the rapid development of high-end material markets such as engineering plastics and new energy vehicles, the industry has raised higher demands for granulation equipment in terms of efficiency, stability, and intelligence. In response to this trend, KraussMaffei uses innovation as its engine, deeply integrating global technological accumulation with local market insights, and continuously expanding the product matrix of the "Golden Power Series."The brand-new ZE 120 goldPower twin-screw extruder (hereinafter referred to as ZE 120 GP) has been officially launched.

The ZE 120 GP not only continues the golden power.®The high-performance genes of the series, coupled with localized innovations and intelligent upgrades, provide customers with system solutions that combine German quality with high cost-effectiveness, injecting new "golden" momentum into material companies to enhance their process levels and gain competitive advantages in the market.

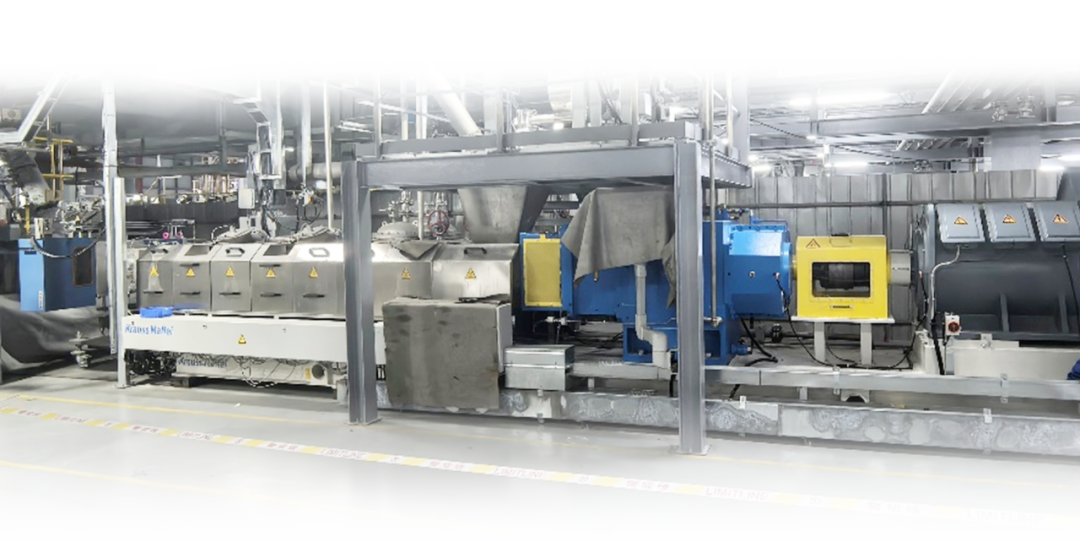

Since its market launch, the new ZE 120 GP has demonstrated its exceptional performance in actual production applications.A large leading chemical enterprise in China.In the collaboration, ZE 120 GP is applied in the granulation production of polycarbonate (PC) powder.Achieve "one-time successful startup" after delivery.and maintain stable operation continuously.The output reaches 4 tons per hour.It fully verifies its reliability and high-efficiency capacity under continuous high-load conditions.

This benchmark case not only demonstrates the excellent stability and output efficiency of the ZE 120 GP but also precisely meets the customer's core needs for high capacity and high purity production. It significantly enhances their delivery capability and cost advantage in both local and global markets, providing strong equipment support for customers to seize market opportunities and consolidate their industry position.

As KraussMaffei Golden Power®An important member of the series, the ZE 120 GP inherits the core technological advantages of the series.

Core component imports ensure production reliability.

The key core components of the equipment are made from high-quality imported brands, ensuring high reliability and exceptional durability of the entire machine at the mechanical level from the source, laying a solid foundation for continuous and stable production.

· 13 high torque, outstanding power.

ZE 120 GP's 13 Nm/cmHigh torque ratioEven when processing difficult-to-machine materials such as high-viscosity engineering plastics, it can still deliver strong shearing and conveying power; at a maximum speed of 400 r/min, it can reach 4 t/h, efficiently broadening the application boundaries.

· Intelligent control, precise and convenient operation.

Equipped with a new generation intelligent control system, it supports precise setting of process parameters, real-time tracking of production data, and intelligent diagnostics. This not only significantly lowers the operational threshold but also comprehensively enhances the control accuracy of the production process and the consistency of the finished product quality.

While adhering to German craftsmanship, the ZE 120 GP deeply integrates KraussMaffei's precise insights into the Chinese market.Value re-upgrading achieved through localized innovation.KraussMaffei has localized the development and production of key process components, significantly optimizing supply chain costs while ensuring that the performance and reliability of the entire machine are fully consistent with global standards. This enables more companies to enjoy the performance and production efficiency of world-class equipment with more competitive investments.

Relying on KraussMaffei's comprehensive service network covering the entire country, customers can enjoy rapid response local professional support. From equipment installation and commissioning, process technology training to regular maintenance and quick troubleshooting, we provide round-the-clock, full-cycle service assurance, minimizing unplanned downtime to ensure the continuous and stable operation of customers' production lines, truly achieving an efficient and worry-free production experience.

The installation of the ZE 120 GP twin-screw extruder perfectly embodies KraussMaffei's development philosophy of "Originated in Germany, Thrived in China, Empowering the World." It inherits the brand's core technological genes while enabling more companies to enjoy world-class equipment performance with optimized local key components and supply chains for better investment. In the future, KraussMaffei will continue to drive innovation, working hand in hand with customers to jointly promote the high-quality development and sustainable transformation of China's chemical granulation industry.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track