Yizumi is deeply involved in the formulation of industry standards, empowering intelligent manufacturing in rubber and plastic molding.

Recently, a discussion meeting for the drafting of three group standards, "Digital Twin for Rubber and Plastic Injection Molding Machines Part 1: General Conditions," "Intelligent Manufacturing Execution System (MES) for Injection Molding Workshops," and "Continuous Loss-in-Weight Feeder," was held in Zhoushan, Zhejiang. Industry experts and corporate representatives from all over the country gathered together to contribute to the standardization process of the plastic machinery industry.

Injection Molding Workshop Intelligent Manufacturing Execution System (MES)

Discussion on the Drafting of Three Group Standards

In the context of the manufacturing industry accelerating its transition to digitalization and intelligent transformation, Yizumi, as a leading enterprise in the field of polymer material forming equipment, has played a key role in the formulation of two industry group standards: "Digital Twin for Rubber and Plastic Injection Molding Machines Part 1: General Conditions" and "Smart Manufacturing Execution System (MES) for Injection Molding Workshops." Leveraging its deep industry and technological expertise, Yizumi contributed strategically forward-looking professional insights during the standard drafting process, propelling the industry's standardization efforts to take significant steps forward.

Yizumi Intelligent Interconnection Research Institute Senior Manager Zhang Yanfei (first from left)

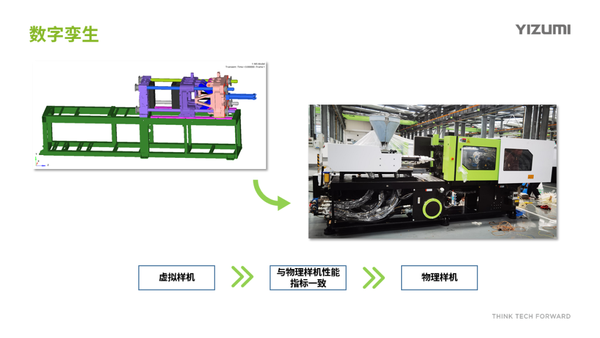

Digital Twin Standards: Leading from Concept to Practice

In terms of data asset security, the Yizumi expert team innovatively recommends establishing a tiered authorization system, introducing mature experiences from other industries in the field of data security into the digital twin of the rubber and plastic molding manufacturing industry. This recommendation not only ensures the security of the company's core process data but also realizes the open sharing of equipment efficiency data, providing new ideas for industry data governance.

Injection Molding Industry MES Standards: Innovative Practices to Fill the Gap

open collaboration: promoting the ecological development of the industry

Yizumi, as a core participating unit in the development of two standards, not only contributed its experience in the deep integration of intelligent control systems and production management systems during the standard research process, but also promoted the establishment of a dialogue channel for a technical platform among equipment manufacturers, software service providers, and end users from the perspective of digital transformation of the industrial chain.

By deeply participating in the formulation of industry standards, Yizumi not only demonstrates its outstanding strength in the technical field but also highlights its responsibility and commitment. In the future, Yizumi will continue to join hands with all parties to promote the digital transformation and high-quality development of the plastic machinery industry, contributing more wisdom and strength to the standardization construction of the industry.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track