Wind Power Resin Material Leader Goes Public!

On September 29th, Daosheng Tianhe, a leading company in wind power resin materials, officially started its subscription process with an issue price of 5.98 yuan per share and a price-to-earnings ratio of 29.05 times, planning to list on the main board of the Shanghai Stock Exchange.

According to reports, the company planned to launch an IPO on the ChiNext board in 2020, but the application was ultimately unsuccessful. In June 2023, the company shifted its focus to the Shanghai Main Board and submitted an IPO application, eventually receiving approval for registration from the China Securities Regulatory Commission in August 2025.

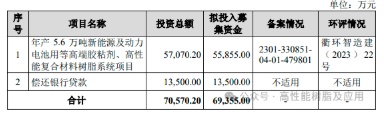

The total amount raised in this IPO is 705.702 million yuan, of which 558.55 million yuan (accounting for 80.5% of the total raised) is planned to be invested in the "project with an annual output of 56,000 tons of high-end adhesives and high-performance composite material resin systems for new energy and power batteries." The annual production capacity of the high-performance composite material resin system is 19,000 tons, and the annual production capacity of high-end adhesives for power batteries and others is 37,000 tons, mainly used in high-tech fields such as wind power generation and new energy vehicles.

According to the information, Daoshengtianhe was established in 2015 and is headquartered in Shanghai. It initially started as an agent for the sales of imported wind turbine blade materials, and later transformed into a strategic focus on independent research and development and production. It is a national high-tech enterprise and a national specialized and innovative "little giant" enterprise.

The company has 7 holding subsidiaries: Yicheng New Materials, Shanghai Chenglai, Jiangsu Daoda, Zhejiang Zhihe, Zhejiang Daosheng, German Daosheng, and Daoheng Yixin. It also has 3 equity-invested subsidiaries: Liyang Caisheng, Shanghai Daoyi, and Guoxing Daosheng.

The company's products are centered around high-performance thermosetting resin materials such as epoxy resin, polyurethane, acrylic, and organic silicon, forming three main product series: materials for wind turbine blades, resins for new composite materials, and industrial adhesives for new energy vehicles. They are primarily used in renewable energy fields such as wind power, new energy vehicles, energy storage, and hydrogen energy, as well as in industries like aviation, oil and gas extraction, power generation, and mold manufacturing.

DaoSheng TianHe is one of the largest manufacturers of epoxy resin for wind turbine blades in the world. In 2024, DaoSheng TianHe achieved sales of 143,100 tons of "epoxy resin series for wind turbine blades" and 15,200 tons of "structural adhesive for wind turbine blades." According to data from the China Petroleum and Chemical Industry Federation, the company has ranked first in global sales of "epoxy resin series for wind turbine blades" for three consecutive years from 2022 to 2024, and ranked second in domestic sales and third in global sales of "structural adhesive for wind turbine blades" during the same period. Additionally, the company is currently the only Chinese enterprise supplying both epoxy resin and structural adhesive for wind turbine blades to the international wind turbine giant Vestas.

In terms of raw materials, the company's products primarily require epoxy resin, as well as curing agents, polyols, and core material raw materials. Suppliers include Yangnong Chemical, Juhua Group, Evonik, BASF, and Chang Chun Group, among others.

In the wind power sector, the company has essentially covered all major wind turbine blade manufacturers in China, including Goldwind Technology, Envision Energy, Mingyang Smart Energy, China Haizhuang, United Power, Shanghai Electric, Vestas, and Nordex Group. In the new energy vehicle sector, its adhesive products are widely supplied to "three electric" system enterprises such as BYD, GAC, Geely, TE Connectivity, Hive Energy, Guoxuan Hi-Tech, Envision Energy, Borui Power, and Ganfeng Lithium. In the field of new composite materials, its resin products have been supplied to clients such as Chongqing Windu, Zhongfu Carbon Fiber, North Glass Institute, Tianguang Wind Power, Taishan Glass Fiber, Jilin Chemical Fiber, Haiyuan Composites, Ningde Kangben, and Zhenstone Group.

In terms of performance, from 2022 to 2024, Daosheng Tianhe achieved operating revenues of 3.436 billion yuan, 3.202 billion yuan, and 3.238 billion yuan respectively, with net profits of 110 million yuan, 155 million yuan, and 155 million yuan respectively. The gross profit margins were 10.77%, 12.35%, and 11.58% respectively. In the first half of 2025, Daosheng Tianhe achieved operating revenue of 1.785 billion yuan and a net profit of 86 million yuan. The company expects that in the first three quarters of 2025, net profit will be between 145 million yuan and 155 million yuan, a year-on-year growth of 48.21% to 58.43%.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track