Whisker Application in Nylon Modification Research

Whiskers, as a high-performance reinforcing material, play a crucial role in enhancing the properties of nylon (especially engineering plastics such as PA6 and PA66).

What is whisker?

It is a type of single crystal fiber material with a complete crystal structure and very small size. It almost lacks common crystal defects (such as dislocations, voids, etc.), hence its strength approaches the theoretical value of interatomic bonding forces.

Main features:

✔ High strength and modulus:Its tensile strength and elastic modulus are far higher than those of ordinary fibers and glass fibers.

✔ High aspect ratio:Conducive to stress transfer, enhancing the effect well.

Heat resistance:Good thermal stability and low coefficient of thermal expansion.

✔Wear resistance:High hardness can significantly enhance the wear resistance of composite materials.

✔ Good dimensional stability:Deformation is small under high temperature and load.

Isotropic enhancement:Unlike long fibers (such as glass fibers), whiskers are short fibers that do not exhibit significant orientation during the injection molding process. As a result, the shrinkage rate and mechanical properties of the product are more uniform in all directions, and it is less prone to warping.

Common types of whiskers used for nylon modification:

Calcium sulfate whiskers

Calcium carbonate whiskers

Zinc oxide whiskers

Potassium titanate whiskers

Boron oxide aluminum whiskers

The main role of whiskers in nylon modification.

Adding whiskers to the nylon matrix can enhance the performance of nylon in all aspects, upgrading it from a "good" engineering plastic to an "excellent" high-performance material.

1. Significantly enhance toughness

Enhancement: Translate the above content into English and output the translation directly, without any explanation.Whiskers, as rigid particles, can effectively bear loads and significantly improve the tensile strength, bending strength, and bending modulus of nylon. Their effect is superior to that of ordinary spherical fillers like calcium carbonate and is comparable to or even better than that of short-cut glass fibers in certain aspects.

Toughening:A unique advantage of whiskers compared to glass fibers is that while glass fiber reinforcement usually reduces the impact strength of materials, suitable whiskers (such as calcium sulfate whiskers) can improve strength while maintaining or even enhancing the impact toughness of nylon. The mechanism is that whiskers can induce crazing, pin cracks, and promote crack deflection and branching, thereby absorbing a large amount of impact energy.

2. Improve heat resistance and heat deformation temperature.

The addition of whiskers can significantly increase the heat distortion temperature of nylon, allowing it to maintain its shape and mechanical properties even in higher temperature environments. This is crucial for high-temperature applications such as engine peripheral components and electronic appliances.

3. Improve dimensional stability and reduce warping.

Reduce molding shrinkage rate:The whiskers restrict the movement of nylon molecular chains, thereby reducing its shrinkage during the cooling process.

Reduce warping.Since whiskers provide isotropic reinforcement, unlike glass fibers which have strong orientation in the flow direction, the shrinkage of the product is more uniform in all directions. This greatly improves the issue of warpage deformation caused by uneven orientation and shrinkage. This is particularly beneficial for manufacturing large, flat, and precise components (such as gears and connectors).

4. Enhance wear resistance and surface performance.

Durability:High-hardness whiskers (such as potassium titanate whiskers) can significantly improve the friction and wear resistance of nylon.

Surface finish:Compared to glass fibers, whiskers are smaller in size and cause less damage to the surface of the product. Therefore, nylon products reinforced with whiskers have smoother and more even surfaces, resulting in better appearance quality.

5. Improve processing fluidity

Some whiskers (such as surface-treated calcium sulfate whiskers) exhibit a certain "ball bearing effect," which can improve the flowability of nylon melts during melt processing, reduce viscosity, and facilitate mold filling, making them particularly suitable for injection molding of thin-walled products or complex structures.

Specific application areas

Based on the excellent combination of performance mentioned above, whisker-reinforced nylon has been widely used in the following fields:

1. Automotive Industry:

Engine peripheral components:Intake manifold, engine cover, thermostat housing, etc. (requiring high heat resistance, high strength, and low warpage).

Transmission system components:Gears, bearing cages, etc. (requiring high wear resistance and high strength).

Other functional components:Door handles, lock cylinders, connectors, etc.

2. Electronics and electrical appliances:

Precision connectors:High dimensional stability and low warpage are required to ensure contact reliability.

Coil framework, miniature circuit breaker housing:Requires good heat resistance and electrical insulation.

Precision components of office equipment:Gears, brackets, etc. inside printers and copiers.

3. Machinery Industry:

Wear-resistant components:Such as bearings, sliders, transmission worm gears, etc.

Precision mechanical parts:Replace some metal parts to achieve lightweight design.

4. Other Fields:

Sports equipment, special tools, etc.

Challenges and Key Technologies

Despite the excellent performance of whiskers, their application also faces some challenges. The core technology lies in addressing these issues.

1. Interface Compatibility:Whiskers are inorganic materials, while nylon is a polar organic polymer. The insufficient interfacial bonding strength between the two can lead to a decline in performance.Surface treatment of crystal whiskersThe key to success or failure. Silane coupling agents, titanate coupling agents, etc., are usually used for surface modification of whiskers to enhance their interfacial adhesion with the nylon matrix.

2. Variability:Whiskers tend to agglomerate, and uneven dispersion in a nylon matrix can create stress concentration points, becoming weak links in the material. It is necessary to ensure their uniform dispersion in the matrix through optimized mixing processes and surface treatments.

3. Cost:The high cost of high-performance whiskers (such as aluminum borate and potassium titanate) somewhat limits their large-scale application. Currently, the cost-effectiveness is extremely high.Calcium sulfate whiskerIt is one of the most widely used varieties in the market.

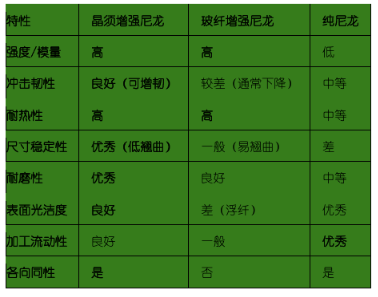

Summary Table:

In summary, whiskers, as a high-performance reinforcement material, provide a way to modify nylon by overcoming issues such as warping, brittleness, and surface roughness associated with traditional fiberglass reinforcement.High strength, high heat resistance, high wear resistance, low warpage, good toughnessThe comprehensive solution is particularly suitable for applications with stringent requirements for dimensional accuracy, surface quality, and overall mechanical properties. It is an important force driving the advancement of nylon engineering plastics towards high-end and precision development.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track