What really determines the impact resistance of plastics? how to choose your ideal plastic?

As reliance on plastics increases, understanding impact resistance to improve performance, safety, and longevity has become more important than ever.

The elasticity of these plastics is largely influenced by interrelated factors such as the molecular structure of the polymer, the presence of copolymers, the addition of reinforcing materials or modifiers, and environmental conditions (such as temperature, etc.).

Impact resistance plays a pivotal role in the design and selection of polymers used in critical applications. These applications range widely, from automotive bumpers and safety equipment to electronic device housings and medical instruments. As various industries seek lighter, stronger, and more environmentally friendly materials, impact-resistant plastics are continually evolving through advancements in nanotechnology, smart polymers, and sustainable design.

Let's delve into the structural design considerations and the effects of polymer blends, additives, and environmental factors on the impact resistance of polymers.

1.What is the impact resistance of plastic?

The impact resistance of plastic refers to the material's ability to withstand sudden impacts without deforming. In terms of its nature, plastic materials can exhibit varying degrees of impact resistance. Some plastics are inherently brittle, while others are ductile and can absorb significant impact energy. Essentially, impact-resistant plastics are designed to balance strength, flexibility, and durability. This enables them to withstand impact forces and provide reliable performance.

Durability (the ability of a material to withstand wear, abrasion, and other forms of degradation over time) and toughness (the ability to absorb energy before fracturing) ensure that impact-resistant plastics can reliably operate in demanding applications.

Impact-resistant plastic properties

When considering impact-resistant plastics, it is essential to understand the specific characteristics that contribute to their ability to withstand impact. Here is a breakdown of some general characteristics of impact-resistant plastics:

High toughness:The ability of a material to absorb energy and undergo plastic deformation before fracturing. It is a key factor in impact resistance.

Flexibility:Some impact-resistant plastics exhibit a certain degree of flexibility, allowing them to bend or deform upon impact, thereby dissipating energy.

Durability:These materials are designed to withstand repeated impacts and harsh conditions, thereby ensuring long-term performance.

Chemical resistance:Many impact-resistant plastics also have good chemical resistance, which is crucial for applications in various environments.

Temperature stability:Maintaining impact resistance within a certain temperature range is crucial because temperature changes can significantly affect the performance of materials.

Lightweight:These plastics typically have a good strength-to-weight ratio, making them ideal for applications where weight reduction is necessary.

Factors affecting the impact resistance of plastics

To achieve high impact resistance in plastics, several factors need to be carefully controlled. The following is a detailed explanation of these factors:

Polymer structureThe impact resistance of plastics is closely related to their structure and composition. The molecular arrangement of plastics significantly affects their ability to absorb impact. Here is a breakdown of these factors:

Polymer chain:The length and arrangement of polymer chains significantly affect impact resistance. Longer chains tend to entangle more, thereby increasing toughness. The presence of flexible segments in polymer chains allows energy absorption during impact.

Co-polymerization:By copolymerization, different monomers are combined to produce materials with enhanced impact resistance. For example, in ABS, the butadiene rubber component provides the necessary flexibility.

Molecular weight:Due to the increase in chain entanglement, high molecular weight polymers usually exhibit greater impact strength.

Additive

Various polymer additives can be incorporated into plastics to enhance their impact strength, such as impact modifiers, plasticizers, nanoparticles, and reinforcements (fillers and fibers). Let's take a closer look at their functions:

Impact modifier:These additives are typically elastomers (rubber polymers) incorporated into the plastic matrix to absorb impact energy. They form a dispersed phase within the polymer matrix, which can deform and dissipate energy. This can prevent crack propagation, thereby allowing the material to exhibit greater ductility and toughness.

Plasticizer:They increase the flexibility and ductility of plastics, enhancing their ability to withstand impact.

Nanoparticles:In some cases, nanoparticles can be added to enhance the polymer matrix and improve impact resistance.

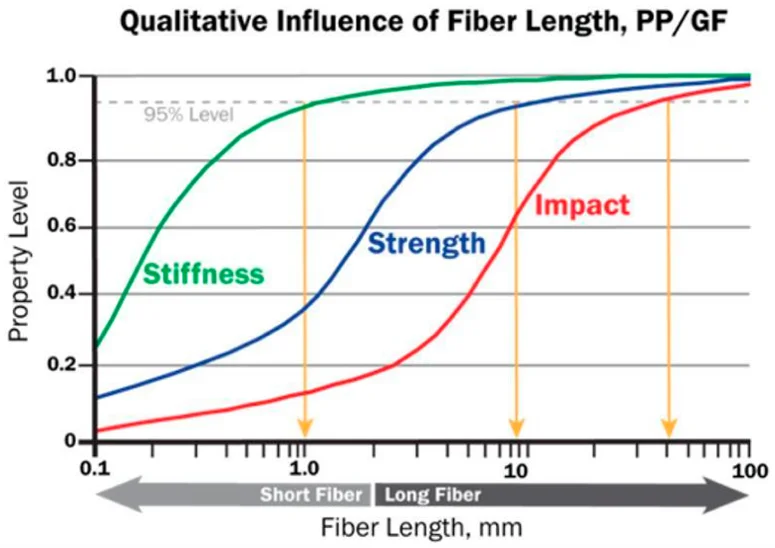

Enhancement AdditiveFibers (such as glass fibers and carbon fibers) and particulate fillers can enhance the polymer matrix, thereby increasing strength and impact resistance. These fillers provide structural support and can absorb impact energy. The size and distribution of the fillers play a crucial role in determining their effectiveness in enhancing impact strength. Differences in aspect ratio can lead to performance differences, and these differences are amplified as fiber length increases. However, in degradation behavior, fibers as a continuous medium can transmit corrosive elements, such as moisture, within the composite material.

The dependence of properties on fiber length in glass fiber reinforced polypropylene (PP)

Polymer blend

Combining different polymers can create blends with customized impact properties. For example, mixing brittle polymers with ductile polymers can produce materials with greater toughness. The key to successful polymer blending is the compatibility of the two polymers.

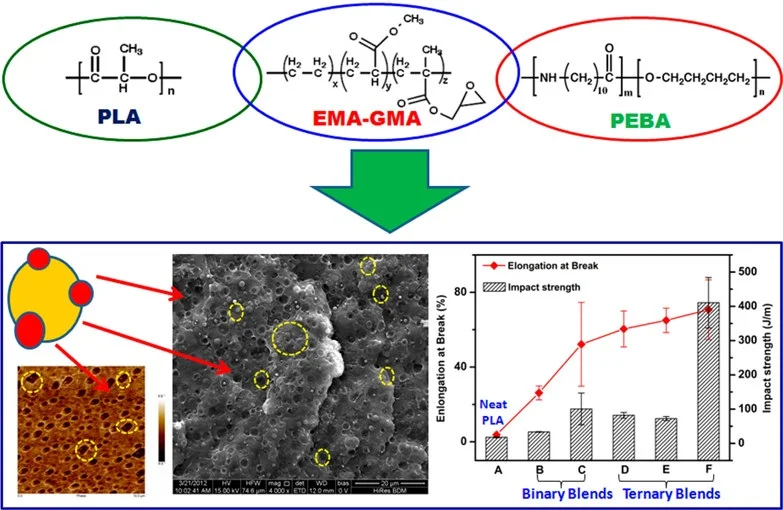

The dispersion of separated polymers in mixtures is very important. Ideally, the impact modifiers should have very fine dispersion within the base polymer. Zhang et al. used ethylene-methyl acrylate-glycidyl methacrylate (EMAGMA) as a reactive compatibilizer for polylactic acid (PLA)/polyether block amide (PEBA) blends, achieving an impact strength of up to 500 J/m while maintaining a tensile strength of 50 MPa.

The performance improvement of these ternary blends is attributed to the unique morphology of partially encapsulating PEBA in the PLA matrix by EMAGMA. Interfacial cavitation and good adhesion between phases result in significant shear yielding in the PLA matrix.

Components, morphology, and impact strength of highly reinforced PLA blends

Many plastics become more brittle at lower temperatures, reducing their impact resistance. At higher temperatures, they usually become more ductile and better able to absorb impacts. However, excessive heat can also soften some plastics, thereby reducing structural integrity.

Material thickness

Generally, thicker materials exhibit higher impact resistance. However, beyond a certain point, increasing thickness may introduce internal stress or affect cooling. This can slightly reduce the overall toughness.

Notch sensitivity

Sharp angles or notches can create stress concentration points, making the material more prone to fracture.

2.Which type of impact-resistant polymer would you like to choose?

When selecting impact-resistant plastics, it's important to understand the characteristics of some of the most commonly used materials. Here are detailed descriptions of some of the most impact-resistant polymers:

High Impact Polystyrene (HIPS)

High-impact polystyrene is a modified form of polystyrene, with added rubber to enhance its impact resistance. It is known for its good impact strength, rigidity, and ease of processing. It is also cost-effective and easy to thermoform. However, it has limited heat resistance and UV stability. Its applications include packaging, electronic housings, toys, and automotive interior components.

Polycarbonate (PC)

Polycarbonate exhibits extremely high impact resistance even at low temperatures. It has a unique molecular structure with long and flexible chains that can easily deform and absorb impact energy. It is also known for its optical transparency, dimensional stability, and high-temperature resistance. Generally speaking, PC shows better impact resistance than ABS. It is a more expensive material. It is used in safety glasses, automotive parts, and electronic device housings.

Acrylonitrile Butadiene Styrene (ABS)

Acrylonitrile butadiene styrene is composed of a rigid styrene-acrylonitrile matrix and dispersed butadiene rubber particles. The rubber particles act as impact modifiers, absorbing energy and preventing crack propagation. Therefore, ABS offers a good balance between impact resistance, rigidity, and processability. It is relatively cost-effective compared to PC and has a good surface finish. It also has good chemical resistance. It is used in automotive interior parts, electronic housings, and consumer goods.

Polypropylene (PP)

The impact resistance of polypropylene varies due to its formulation. PP copolymers have higher impact resistance than homopolymers. It is known for its chemical resistance and fatigue resistance. It becomes brittle at low temperatures. It is used in applications such as automotive bumpers, packaging, and industrial components.

Polyethylene (PE)

Polyethylene exhibits excellent chemical resistance and low-temperature flexibility. In certain forms, PE can have very high impact resistance. High-density polyethylene (HDPE) has good impact resistance, especially in thicker forms. Low-density polyethylene (LDPE) and linear low-density polyethylene (LLDPE) have moderate impact resistance, with LLDPE having better impact resistance than LDPE. It is commonly used in packaging, pipes, and containers.

Nylon (Polyamide/PA)

Nylon has good impact resistance, especially when reinforced. It is also known for its excellent wear resistance and chemical resistance. It can absorb moisture, which affects its performance. It is used in gears, bearings, and automotive components.

Thermosetting plastic

Generally, thermosetting plastics have higher strength and temperature resistance. The impact resistance varies greatly depending on the specific thermosetting resin and reinforcing fillers. However, when high impact resistance is required, thermoplastic plastics are preferred. Examples of thermosetting plastics include epoxy resin, polyester resin, and phenolic resin.

Benefits and Pain Points of Impact-Resistant Plastics

Understand the considerations when choosing impact-resistant polymers by comparing the main advantages and pain points mentioned in the table below.

They provide important protection in applications that may be subject to impact, reducing the risk of injury and damage.

They can withstand weather conditions, chemicals, and other environmental pressures, making them suitable for harsh environments.

They can be molded into various shapes and forms to achieve innovative product designs.

They offer a favorable strength-to-weight ratio, which contributes to lighter products and improved efficiency.

They extend the product's lifespan by withstanding wear, tear, and impact. This reduces the need for frequent replacements, saving costs and resources.

Many impact-resistant plastics are easy to process, which reduces manufacturing costs.

They help improve vehicle fuel efficiency and reduce transportation costs.

Impact on performance:

Some impact-resistant polymers may be more difficult to process and require specialized equipment and techniques.

Some are sensitive to certain chemicals, limiting their applications in specific environments.

Compared to other materials, certain impact-resistant plastics (such as PC) have lower scratch resistance. PC can easily fail when notched or scratched. Long-term exposure to UV light can reduce the impact resistance of PC.

Recycling Challenge:

Many impact-resistant plastics are polymer blends that are difficult to separate and recycle.

Additives used to enhance impact resistance can complicate the recycling process.

Pollution from other materials will reduce the quality of recycled plastic.

Separating different types of plastics is a complex and costly process.

Cost issue:

The cost of raw materials may fluctuate, affecting the price of impact-resistant plastics.

Specialized manufacturing processes will increase production costs.

Balancing cost and performance is a challenge because higher impact resistance often comes with a higher price.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track