What is the principle of optical brighteners and which plastics are suitable for them?

Fluorescent Whitening Agent (FWA), also known as Optical Brightening Agent, is a compound capable of absorbing light in the ultraviolet and violet regions of the electromagnetic spectrum and re-emitting it as blue light.

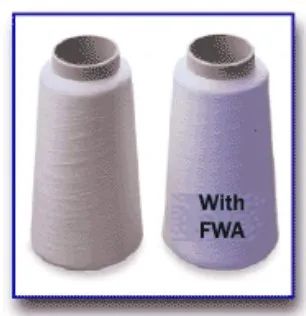

These additives are typically used to enhance the color appearance of fabrics and paper, creating a "whitening" effect by increasing the total amount of reflected blue light, making the material appear less yellowish. Therefore, they are also often used in thermoplastic materials for injection molding.

This article will provide a detailed introduction to the mechanism of action and the effectiveness of optical brighteners.

1Why use fluorescent whitening agents?

Fluorescent whitening agents are also known as optical brighteners.The functions of such additives are as follows:

1. Brighten the color

2. Covering up the natural yellowing of plastic

3. Improve the initial color

Make colored or black pigment products shine.

These fluorescent whitening agents work through a fluorescence mechanism.Absorb ultraviolet light and emit light in the blue region of the visible spectrum, making clothes look brighter and fresher.

Some recommended uses of fluorescent whitening agents include:

1. Molding thermoplastic plastics

2. Films and Sheets

Fiber

Adhesive

5. Synthetic leather

Let's take a detailed look at fluorescent whitening agents, their mechanisms of action, and benefits...

2Operating mechanism

Fluorescent whitening agents or optical brightening agents (FWA) are colorless to slightly colored organic compounds that, when in solution or applied to substrates, absorb ultraviolet light and re-emit most of the absorbed energy as blue fluorescence in the 400-500 nanometer range.

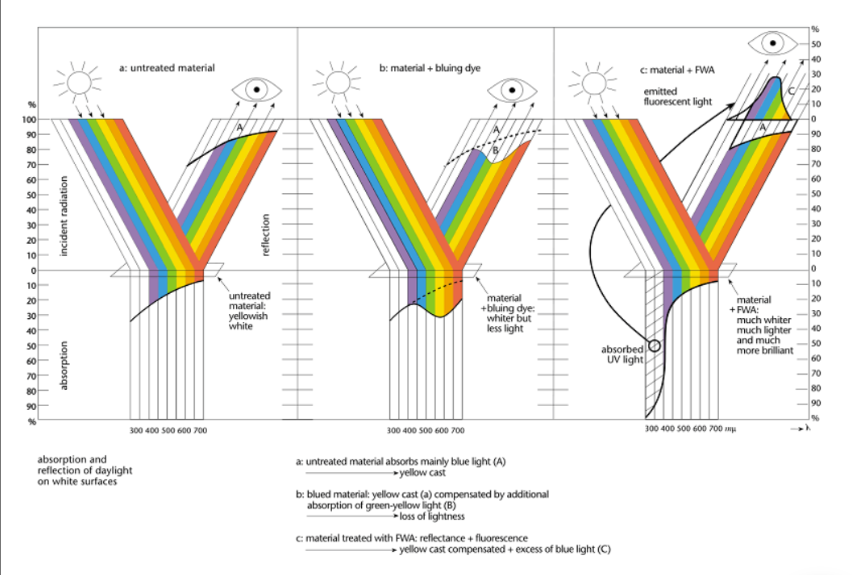

If a material can uniformly reflect most of the light of all wavelengths that shine on its surface, it appears white to the human eye.

For example, natural fibers usually absorb more light in the blue region of the visible spectrum ("blue defect") than other fibers due to the presence of impurities (natural pigments).Therefore, natural fibers also exhibit this light yellow color.

Synthetic fibers also have this light yellow color, although not as pronounced.

The whiteness of the substrate can be improved by enhancing reflectivity or compensating for the blue deficiency.

Before the advent of fluorescent whitening agents (FWA), the common practice was toUse a small amount of blue or purple dye to enhance the visual effect of white.These dyes absorb light in the green-yellow region of the spectrum, thereby reducing brightness.

However, since they simultaneously shift the hue of the yellow material towards blue, the human eye perceives an increase in whiteness.Unlike dyes, optical brighteners can counteract yellowish tints and enhance brightness because their blueing effect is based on adding blue light rather than subtracting yellow-green light.

Fluorescent whitening agents are actually colorless compounds that, when present on a substrate, primarily absorb invisible ultraviolet light in the 300-400 nanometer (nm) range and re-emit visible violet to blue fluorescence. In other words, they can absorb invisible short-wavelength radiation and re-emit visible blue light, thereby making the light reflected by the substrate appear brighter and whiter, which is key to the effectiveness of fluorescent whitening agents.

3How do fluorescent whitening agents work?

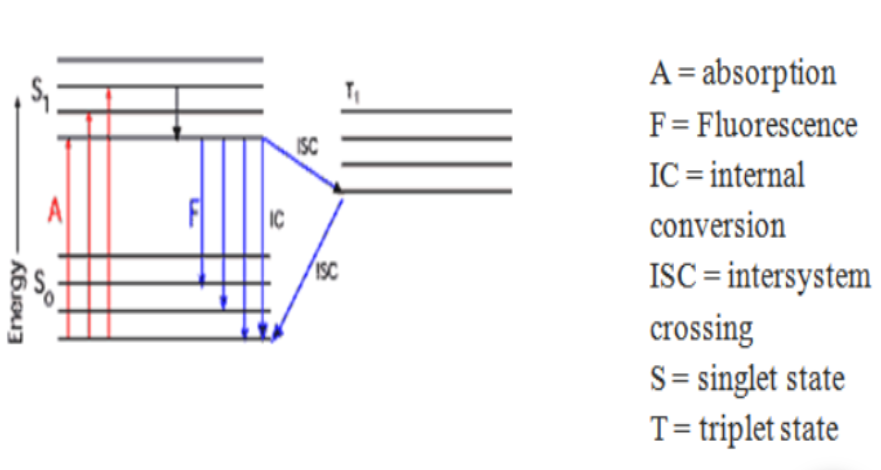

The molecule of the whitening agent absorbs photons (A), which induces a transition from the singlet ground state S.0Transition to the electronically excited singlet state (S1The vibrational energy levels of.

Located in S1The whitening agent in its excited state can be deactivated through various pathways. Fluorescence is generated by the transition of radiation to the vibrational energy level of the ground state (F).

The deactivation processes competing with fluorescence mainly include non-radiative deactivation to S.0Internal conversion (IC) and non-radiative transition to the triplet state (intersystem crossing, ISC).

Fluorescence efficiency is measured by quantum yield.Quantum yield (Φ) = Number of quanta emitted / Number of quanta absorbed

The relative rate of fluorescence emission and competitive processes determine it. When the brightener is fixed on a solid matrix, it emits fluorescence with a high quantum yield.

Fluorescent whitening agent and its transition energy diagram

4The polymer matrix of fluorescent whitening agents.

Fluorescent whitening agents (FWA) can be effectively used for a variety of polymer substrates.Engineering plastics (such as polyester, polycarbonate, polyamide, and acrylic resin)Thermoplastic polyurethane, polyvinyl chloride, styrene homopolymers and copolymers, polyolefins, adhesives, and other organic substrates.

The effectiveness of optical brighteners depends on the type of substrate, processing conditions, and interaction with other components in the formulation (such as white pigments or UV absorbers). Generally, optical brighteners can be effective at very low concentrations.

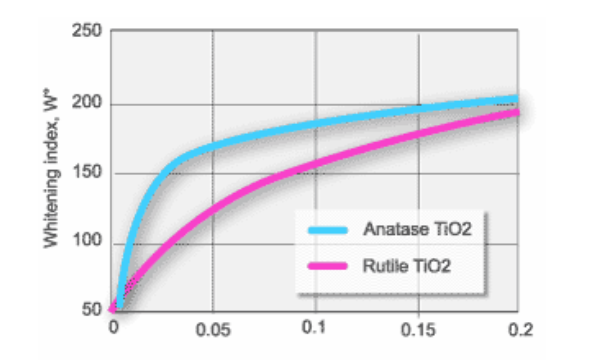

Titanium dioxide pigment (TiO2It absorbs light within the same ultraviolet wavelength range as fluorescent whitening agents, so it also produces a lower level of whiteness.

Fluorescent Brighteners in Flexible PVC

Anatase-type titanium dioxide pigment absorbs about 40% of incident radiation at a wavelength of 380nm, while rutile-type titanium dioxide pigment absorbs about 90%.

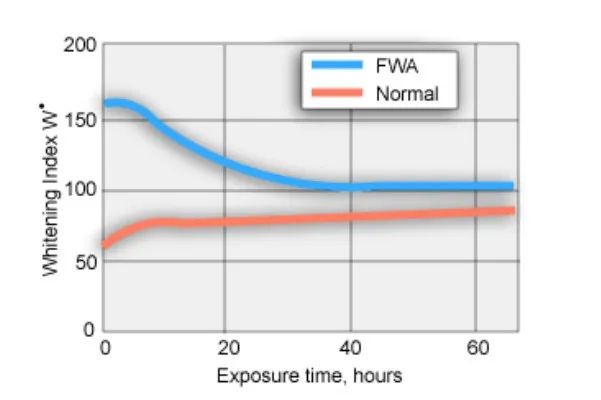

In flexible PVC samples, a bright white color can be achieved by using only a low concentration of fluorescent whitening agent (FWA) and anatase titanium dioxide. When using rutile titanium dioxide, the whiteness slightly decreases at the same concentration. The following two images demonstrate the advantages of fluorescent whitening agents.

The light resistance of the whitening effect of soft PVC.

Fluorescent brighteners in PET fibers

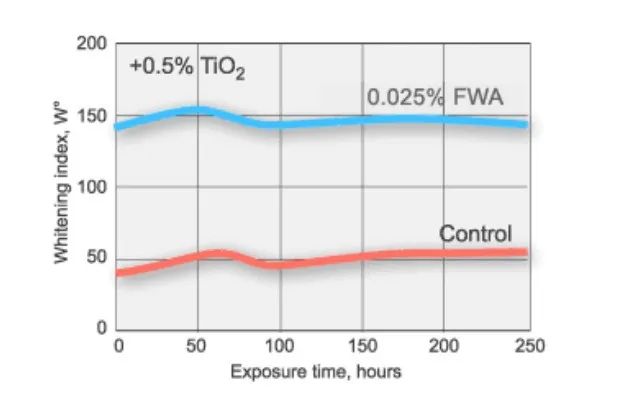

A key criterion for the applicability of fluorescent whitening agent technology is its lightfastness in the substrate. The diagram below shows the stability of the whitening agent in PET fibers:

(Light Fastness of Whitening Effect on PET Fibers)

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track