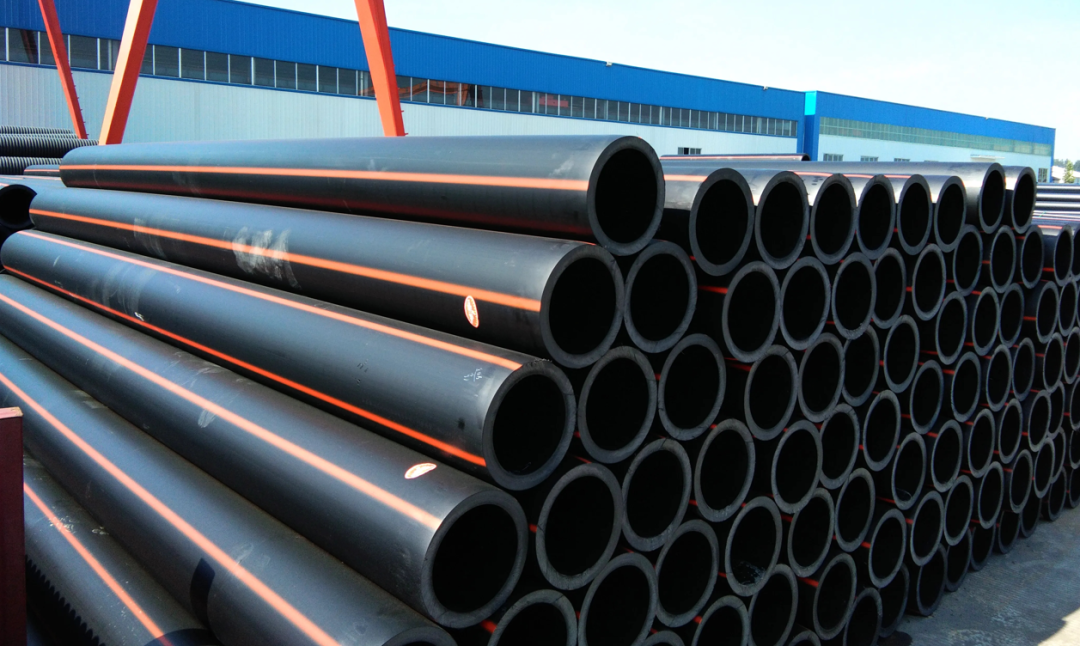

What Is HDPE [Double Resistance] Pipe? How Is It Different from Ordinary PE Pipe?

HDPE mining pipes are made from high-density polyethylene (HDPE) as the base material, with the addition of conductive carbon black (antistatic agent) and flame retardants (such as decabromodiphenyl ether and antimony trioxide). After special modification and granulation, these materials are used to produce the pipes.

This type of pipe not only possesses the inherent advantages of HDPE such as high strength, corrosion resistance, wear resistance, and light weight, but also meets the antistatic and flame-retardant performance requirements of the coal industry standard MT 558.1-2005 "Plastic Pipes for Coal Mine Underground Use Part 1: Polyethylene Pipes." Therefore, HDPE mining pipes are widely used in underground coal mine applications such as gas drainage, water supply and drainage, and ventilation.

2. Characteristics of HDPE Double Anti-corrosion Pipe

- Flame retardant and anti-static (the core differences from ordinary PE pipes)

During the production process of PE twin-antistatic pipes, antistatic agents and flame retardants are uniformly incorporated, ensuring that their performance does not degrade over time. These pipes not only meet the coal industry standard MT558.1-2005, but are also particularly suitable for underground environments that are flammable and explosive.

Lightweight and easy to install

The pipe material has a low density; compared to steel pipes and fiberglass pipes, its weight is significantly reduced, making transportation and installation more convenient, lowering the intensity of downhole operations, and improving construction efficiency.

● Corrosion resistance and scale prevention

In high-sulfur water quality or environments containing calcium and magnesium ions, the pipe material exhibits excellent corrosion resistance and anti-scaling properties, saving costs on corrosion prevention and descaling, and extending service life.

Self-lubrication and flexibility

The inner wall is smooth, resulting in much lower conveying resistance compared to steel pipes and fiberglass pipes, thereby increasing conveying capacity. At the same time, it has good flexibility and can adapt to geological subsidence and complex working conditions.

● Anti-aging and wear resistance

The pipe material exhibits excellent anti-aging performance and retains its toughness even at low temperatures. According to tests, its wear resistance is approximately four times higher than that of steel pipes, significantly extending its service life.

- Impact resistance and high toughness

The low-temperature embrittlement temperature is extremely low, featuring high elongation at break and impact resistance, effectively reducing damage.

● Flexibility and easy connection

The pipe has good flexibility, allowing it to bend easily where needed. Meanwhile, the mining PE pipe uses methods such as hot-melt connection, pipe clamp connection, or flange connection, making the construction process simple and convenient.

3. Application Fields of HDPE Double Anti-corrosion Pipes

Due to its unique properties, PE double-walled pipe is widely used in various pipeline systems underground in coal mines, including:

● Gas extraction pipe

● Water supply and drainage pipes

● Spray Dust Suppression Pipe

● Ventilation duct

● Negative pressure pipeline

In addition to coal mines underground, PE dual-resistant pipes can also be seen in special environments requiring flame retardancy and antistatic properties, such as some petrochemical plants and power plants.

4. Industry Standards and Safety Signs

In order to ensure the quality and safety of polyethylene pipes for coal mines, the state has formulated corresponding industry standards, such as:

● MT 558.1-2005

Plastic pipes for underground coal mines—Part 1: Polyethylene (PE) pipes

● MT 181-1988

Safety Performance Inspection Standards for Plastic Pipes Used in Underground Coal Mines

● AQ1071-2009

Safety Technical Requirements for Non-Metallic Gas Transmission Pipes Used in Coal Mines

These standards provide important guidance and basis for the production, inspection, and application of polyethylene pipes used in coal mines.

In addition, polyethylene pipes used in coal mines must obtain a Coal Mine Safety Mark Certificate (CMSC) before being put into use. This certificate is a necessary proof to ensure that the pipes meet national safety standards and can be safely used in coal mine environments.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track