What is 24-hour water absorption rate? how does it affect plastics? index of water absorption rates for common plastics and their modified materials!

The 24-hour water absorption rate is a crucial performance metric in the plastics industry. It indicates how much moisture a plastic material will absorb over a period of time, which directly affects dimensional stability, mechanical properties, and electrical insulation characteristics.

High water absorption can cause materials to swell, warp, and lose strength, reducing performance in applications expected to be exposed to humid environments. This characteristic will help you select the appropriate materials for specific environments, especially in outdoor, humid environments or components in contact with liquids.

Let's understand how water absorption rate allows plastic manufacturers to predict potential issues and implement necessary design modifications to ensure product reliability throughout its lifespan.

Absorption rate

Absorption of water, also known as hygroscopicity, refers to the ability of a polymer to absorb moisture from the environment. The absorbed moisture acts as a plasticizer, which can reduce the glass transition temperature and strength of the plastic. This is a reversible effect. However, the absorbed moisture may also lead to irreversible degradation of the polymer structure.

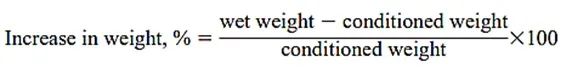

What is the formula for calculating water absorption rate?

The water absorption rate is expressed as a percentage of the weight of the plastic sample or the percentage increase in weight.

What are the test conditions for water absorption rate?

24-hour water absorption rate at 23°CSoak the plastic sample in distilled water at 23°C for 24 hours.

100°C water absorption rate after 24 hoursSoak the plastic samples in distilled boiling water for 24 hours.

Saturated Water Absorption RateImmerse the plastic sample in distilled water at 23°C. Measurements are taken when the polymer no longer absorbs water.

Balanced Water Absorption RateExpose plastic samples to a humid environment (usually with 50% relative humidity) and place them at a specified temperature (23°C or 73.4°F) for 24 hours. The equilibrium moisture content can be used to compare the amount of water absorbed by different types of plastics in a humid environment.

Absorption of water can cause what effects?

Some known impacts include:

Changes in size and mass due to water absorption (e.g., expansion)

● Extraction of water-soluble components

Mechanical properties (elasticity, tensile strength, impact strength) and changes in electrical properties

Exposure to humidity, soaking, and boiling water causes distinctly different reactions in materials.

How does water absorption change the processing and properties of materials?

The effects on thermoplastics

The data on water absorption is crucial for understanding the performance of polymer materials during processing. For instance, it can prevent premature failure due to moisture when injection molding in water or humid environments.

Absorption of moisture is particularly detrimental to plastic products. Moist materials are also more permeable. For example, the carbon dioxide permeability of moist PA6 is three times that of dry PA6.

The presence of moisture in the material structure can also affect insulation and dielectric properties.

The absorption and presence of moisture in the polymer structure is one of the factors leading to material aging.

Polyolefins such as PE, PP, and polybutene do not contain hydrolyzable chemical bonds, resulting in very low water absorption. Therefore, they are basically unaffected after aging in water.

Excessive moisture can reduce the viscosity of plastics, which is the cause of many processing problems.

The moisture in the material can also affect the appearance of the parts.

For example, if the injection molding process uses wet granulation, the reaction occurs in water during the plasticizing stage. Hydrolysis can lead to changes in the material structure (degradation), resulting in a decline in mechanical properties, particularly toughness and resistance.

Injecting with moist PMMA particles will result in poor surface quality of molded parts, and POM injection will also lead to defects in the molded parts.

For PET and PBT materials, hydrolytic degradation can lead to the appearance of short-chain molecules, resulting in a significant decline in the mechanical properties of the materials.

The presence of moisture can weaken the impact strength and mechanical strength of polyamide.

Effects on thermal composite materials

The water absorption process of composite materials is more complex than that of pure polymers. For thermoplastic composites, the degree of water absorption by the polymer matrix depends on the chemical nature and morphology of the polymer, the volume fraction and structure of the fibers, and whether capillary action occurs at the interface.

Factors affecting water absorption rate.

- Type of plastic

- Morphology (crystalline, amorphous...)

The types and proportions of additives, fillers, and reinforcement materials used.

Fiber fraction and orientation (in composites)

● Relative humidity and temperature

- Duration of exposure

How to measure the water absorption rate of plastic?

The most widely used standards for measuring the water absorption of plastics are ASTM D570 and ISO 62.

ASTM D570 - Standard Test Method for Water Absorption of Plastics

The water absorption test method has two main functions:

● 1A - As a reference for the water absorption rate of materials. Applicable in situations where the relationship between moisture and electrical or mechanical properties, dimensions, or appearance has been determined.

● 1B - As a guide to the effects of exposure to water or moist environments on such characteristics.

● 2 - As a control test for product uniformity. It is especially suitable for testing sheets, rods, and tubes of finished products.

Absorption rate test procedure:

Place the sample in the oven and dry it according to the specified time and temperature.

● Then place them in the dryer to cool.

Cool down and weigh the sample immediately.

Then immerse the materials in water at a temperature typically of 23°C for 24 hours or until equilibrium is reached.

Take out the sample, pat it dry with a lint-free cloth, and then weigh it.

ISO 62 Plastics - Determination of water absorption

It describes the procedure to determine the following:

Solid plastics with flat or curved shapes have moisture absorption properties in the "thickness direction."

The amount of water absorbed by a specified size plastic sample when immersed in water or exposed to humid air under controlled conditions.

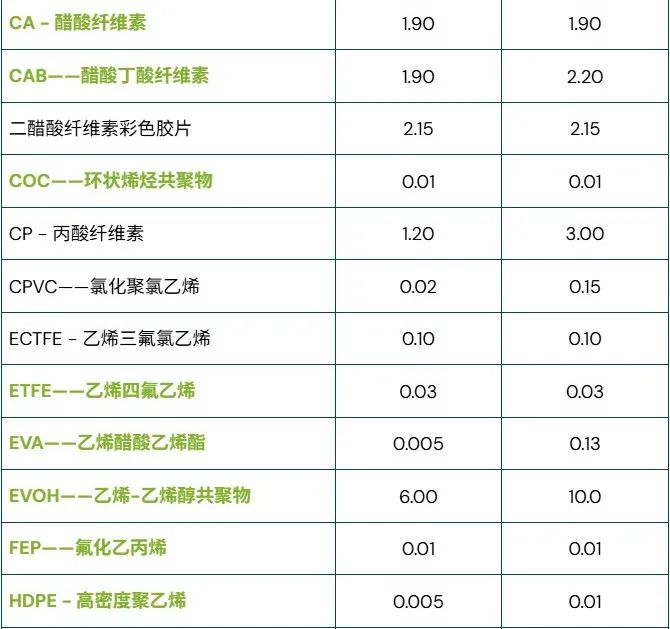

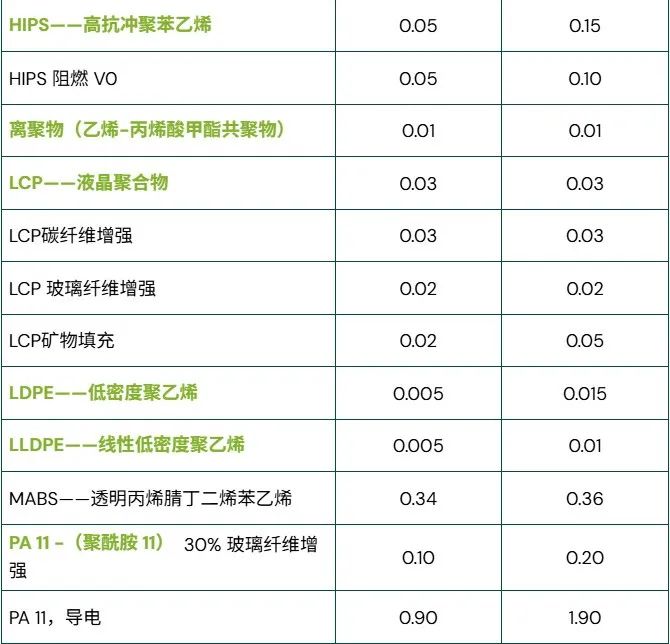

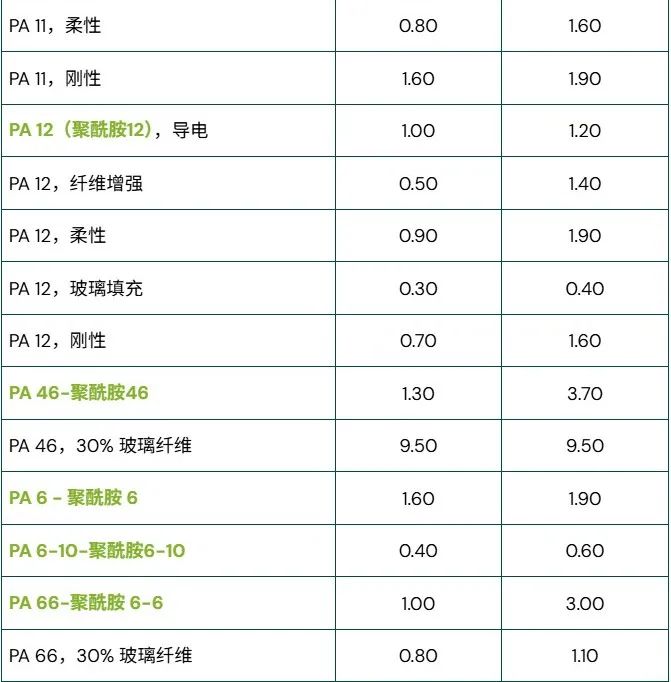

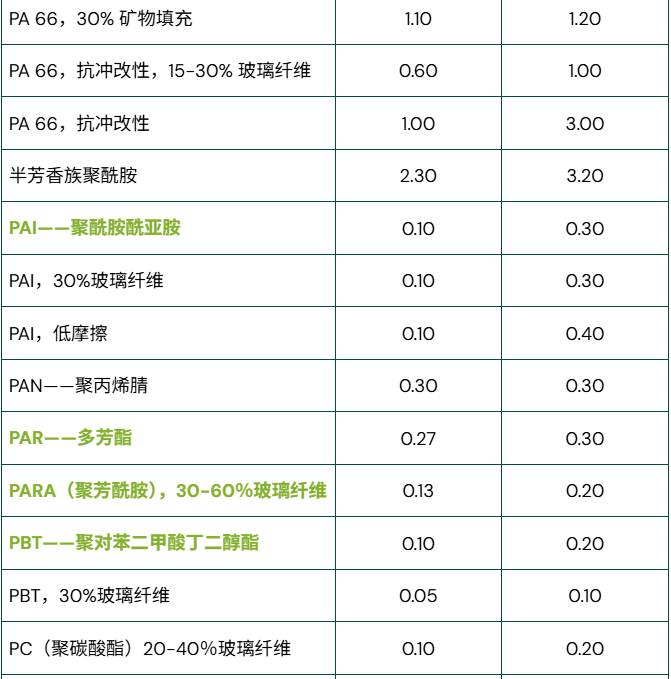

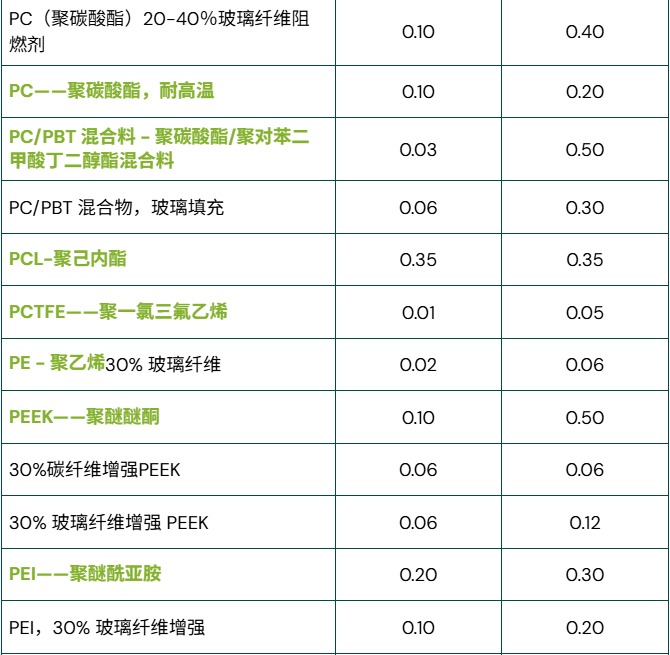

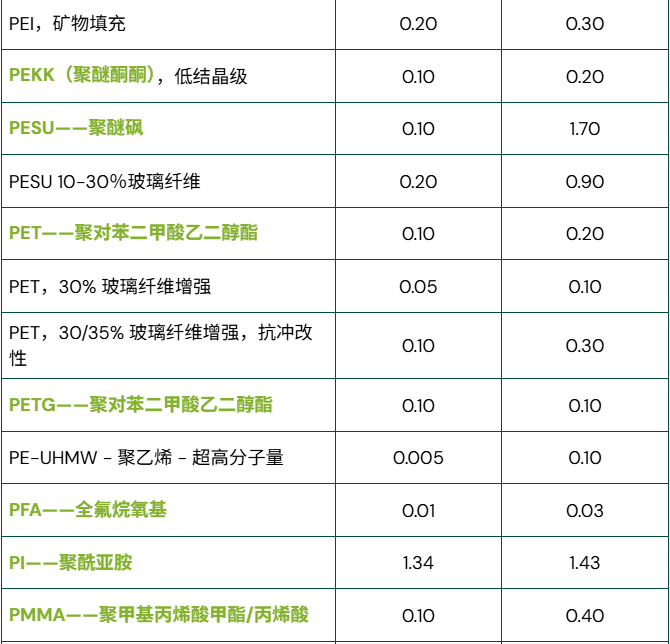

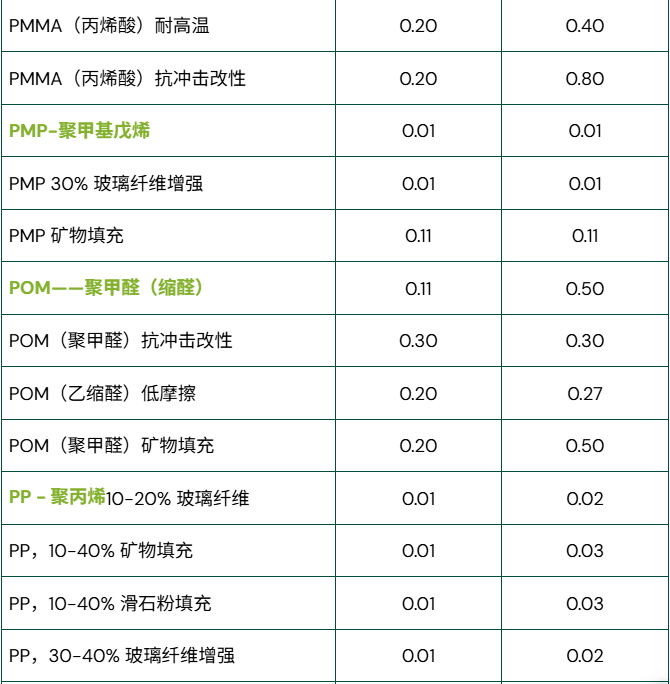

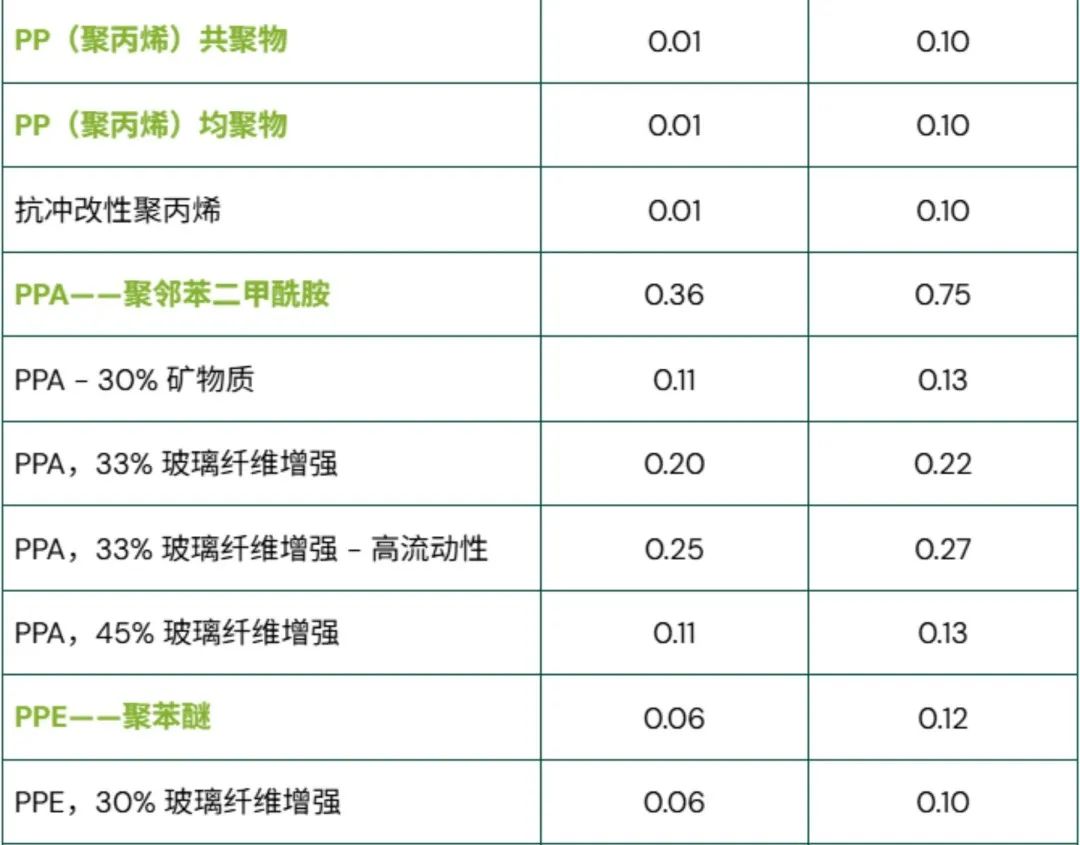

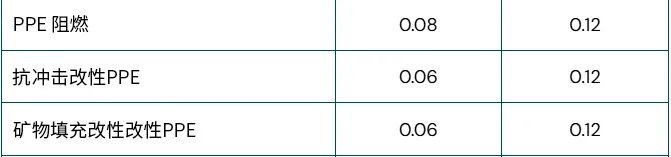

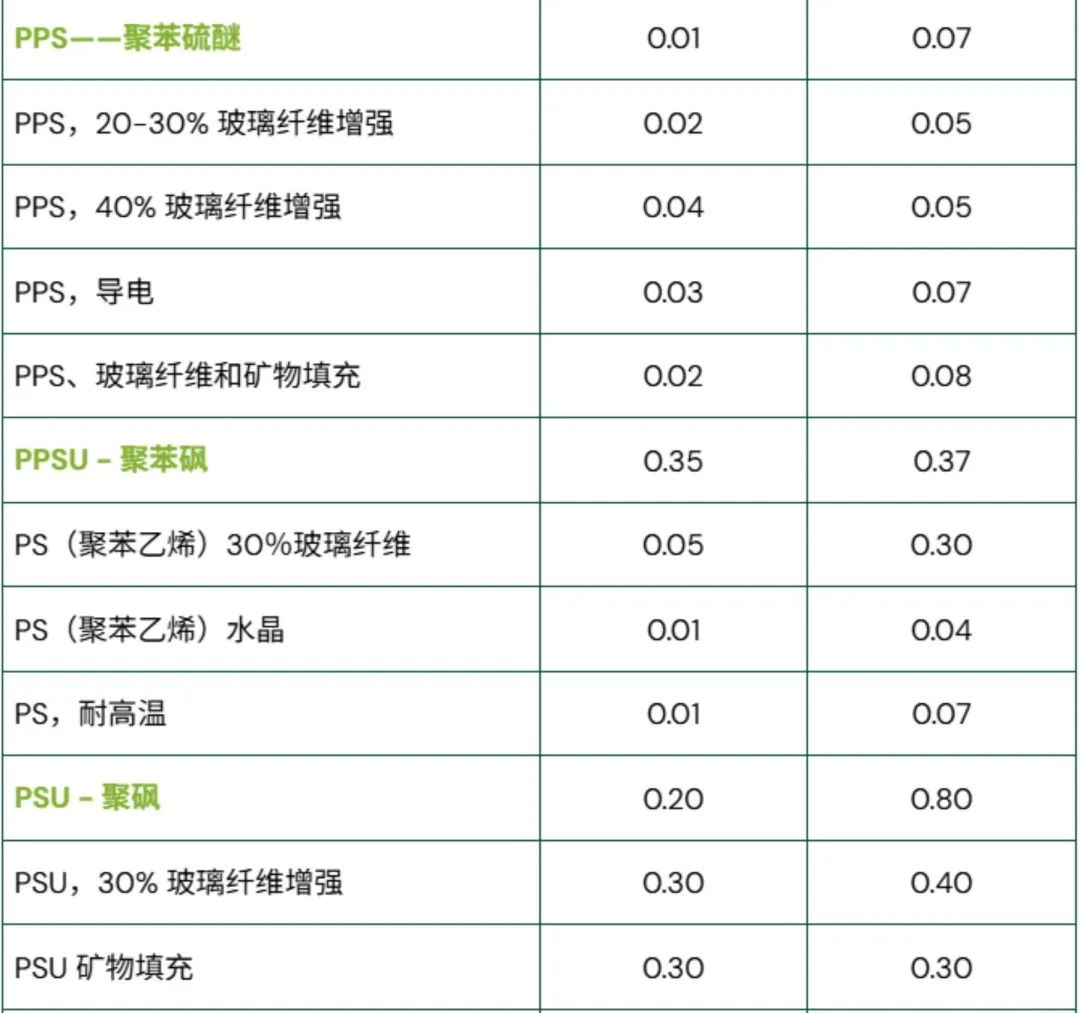

A Review of the Water Absorption Rates of Common Plastics

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track