What Are the Special Features and Advantages of a Lateral Vacuum Device for an Extruder?

In the plastic extrusion industry, vacuum degassing is a crucial process step. To improve product quality and remove volatile impurities from raw materials, different types of vacuum extraction devices are widely used. Among them, the "lateral vacuum extraction device" has gradually gained attention in the industry in recent years.

So, what are the differences between it and the traditional "top vacuum extraction" devices? This article will provide a concise analysis based on professional interview content.

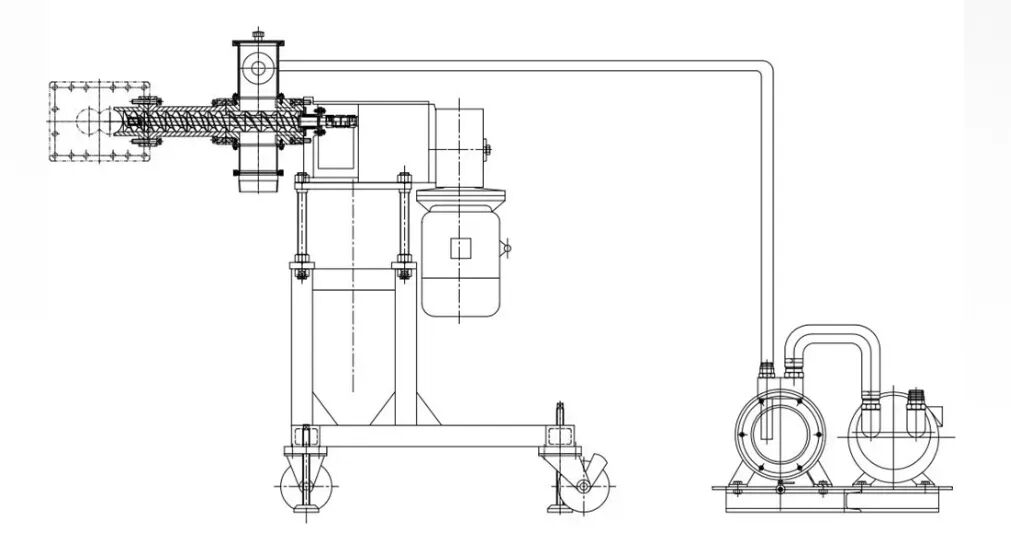

Lateral Forced Vacuum System Diagram: Meizhilong

Lateral vacuum extraction vs. top vacuum extraction: structural differences.

Traditional vacuum extraction devices are mostly placed above the extruder. The principle is to remove volatiles from the material through negative pressure. However, this method tends to pose a risk of "material overflow" during high-output processing or when processing specific raw materials. "Material overflow" refers to the phenomenon where material is sucked out at the vacuum port, leading to contamination or equipment malfunctions.

The lateral vacuum extraction device effectively avoids this problem.The design places the vacuum inlet on the side, and since the rotation direction of the screw is inward, the raw materials are continuously pressed into the screw channel during rotation, effectively preventing the material from being drawn out. This not only enhances process stability but also avoids the hassle of frequently cleaning the vacuum system. It resolves the quality issue of product discoloration caused by top vacuum backflow, and cleaning the vacuum without stopping the machine will not contaminate the product.

Is a higher vacuum level always better?

This is a common misconception. Many people believe that vacuuming is "the stronger, the better," but this is not actually the case. In the degassing process, the key is not the degree of vacuum, but a continuous, stable negative pressure environment and a sufficiently large pumping capacity.

An experienced operator stated, "Generally, we aim for negative pressure, but there's no need to pursue an extremely high level of vacuum. The key is to avoid blockages and material overflow, and to ensure stable operation of the vacuum system." In fact, the effectiveness of vacuuming is closely related to screw design, temperature control, and speed coordination.

Key factors affecting desorption efficiency

In addition to the vacuum system itself, the desorption effect is also influenced by the following factors:

1. Temperature control:To release volatile substances from the material, appropriate temperature support is necessary. If the temperature is too low, the volatiles will not be sufficiently released, while too high a temperature may lead to material degradation.

Screw speed:The rotational speed determines the residence time of the material and also affects the devolatilization efficiency.

3. Threaded block design:Different combinations of threaded blocks can affect the distribution and shear state of the material, thereby influencing the release of volatile components.

The emergence of lateral vacuum extraction devices provides a more stable and safe solution for volatilization, especially suitable for process scenarios that are sensitive to volatilization materials or contain a high level of volatile impurities. Although it occupies some space, its advantages are evident from the perspective of practical application.

When selecting a vacuum system, we should comprehensively consider the process requirements, equipment layout, and material characteristics, rather than just looking at the "vacuum degree" indicator. It's not about extracting as vigorously as possible, but about extracting 'correctly'.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track