[Weekly New Materials Report] Huicheng Environmental Protection 200,000 Ton Project Resumes Production Smoothly! European Giants' Factory Closures Trend Spreads!

Weekly New Materials Frontier

01

Company News

On October 10, Saisir (601127.SH), which recently announced a 11.5 billion yuan investment in Huawei's automotive smart platform, released a statement saying that its subsidiary, Chongqing Phoenix Technology Co., Ltd. (hereinafter referred to as "Saisir Phoenix"), has signed a "Embodied Intelligence Business Cooperation Framework Agreement" with Beijing Volcano Engine Technology Co., Ltd. (hereinafter referred to as "Volcano Engine").

BASF has agreed to sell a majority stake in its coatings business to private equity firm Carlyle Group and Qatar Investment Authority. This business includes automotive OEM coatings, automotive refinish coatings, and surface treatment operations, with a valuation of 7.7 billion euros. BASF will retain a 40% stake in the coatings business and will receive approximately 5.8 billion euros in pre-tax cash proceeds upon the completion of the transaction.

Recently, Dow announced that it will permanently close its polyether polyols production facility at its Tertre plant in Belgium by the end of the first quarter of 2026. The plant has a polyether polyols production capacity of 94,000 tons per year.

Last year, Dow announced a strategic review of its European assets, with a particular focus on its polyurethane business. The decision to close the polyether polyol production facility at its Tertre plant in Belgium was also based on the previous strategic assessment.

On October 6, INEOS confirmed plans to close two production plants located in Rheinberg, Germany, resulting in the loss of 175 jobs. The direct reasons for the planned plant closures are the high costs of energy and carbon emissions, as well as the lack of tariff protection.

Both factories produce essential chemicals. The allyl chemicals division produces a key component of epoxy resins, which are crucial for defense, aerospace, automotive, and renewable energy infrastructure. The electrochemical plant produces chlorine, essential for clean water, pharmaceuticals, industrial processes, and sanitation facilities. On the following day, October 7, INEOS further announced that it would cut 20% of the workforce at its acetyl plant in Hull, UK. INEOS attributed the cause to the impact of cheap high-carbon imported products.

On October 2, Arlanxeo, a subsidiary of Saudi Aramco and one of the world's largest synthetic rubber suppliers, announced plans to cease operations at its synthetic rubber production facility in Port Jérôme, northern France. Arlanxeo stated that its factory is facing challenges such as "rising costs, global market imbalance, and increased regulatory pressure," leading to ongoing losses and the inability to find any viable way to improve profitability. Currently, the synthetic rubber production capacity at the Port Jérôme facility is 140,000 tons per year, with products including neodymium polybutadiene rubber (Nd-PBR) and solution polymerized styrene-butadiene rubber.

On October 8, Swiss industrial giant ABB announced that it had reached an agreement with Japan's SoftBank Group to sell its robotics business unit for $5.375 billion. This news instantly electrified the global technology and industrial sectors, driving SoftBank's stock price to surge by 13% at one point on October 9, setting an intraday high.

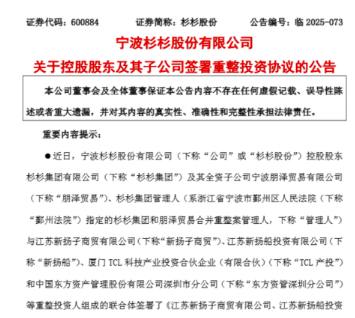

Recently, a significant piece of news emerged in the capital market of the new energy materials sector—Sunshine Co., Ltd. (600884.SH) announced that its controlling shareholder, Sunshine Group Co., Ltd., and its wholly-owned subsidiary Ningbo Pengze Trading Co., Ltd., have officially signed a "Restructuring Investment Agreement" with a newly formed investment consortium.

This news marks the official entry of the Shanshan Group, which has endured two years of family disputes and debt crises, into a "restructuring and rebirth" phase dominated by external capital, setting a crucial tone for the future direction of this leading Chinese lithium battery materials company.

02

Production Capacity Dynamics

Recently, Shanghai Cathay Biotechnology Co., Ltd. (Cathay Biotech) announced that the company will postpone the date when the fund-raising project "Annual Production of 500,000 Tons of Bio-based Cadaverine and 900,000 Tons of Bio-based Polyamide" reaches its scheduled usable state. Due to the current project's park infrastructure and production conditions still needing improvement, the company has decided to extend the project's completion date from December 31, 2025, to December 31, 2027.

Recently, Longhua New Materials (301149.SZ) stated on the investor interaction platform that the company's polyamide series products include PA66 and specialty nylon, which are widely used in toothbrush bristles, drone fan blades, food and beverage packaging, high-end electronics and appliances, high-speed rail, automotive parts, machinery, and other fields. There are still many processing and manufacturing steps between the company's products and the downstream end products, and the specific usage scenarios are determined by downstream customers based on their own needs.

According to reports, Longhua New Material currently has a production capacity of 40,000 tons of polyamide resin, including PA66 and specialty nylon products. Barrier nylon MXD6 is classified as a specialty nylon. It is also stated that the company's polyamide products can be compounded with carbon fiber to produce thermoplastic composites.

On October 8th, Xinhua News Agency reported under the title "Huajin Amoco Project Remains Operational During National Day and Mid-Autumn Festival Holidays" that the Huajin Amoco fine chemical and raw materials engineering project continued work without interruption during the "Double Festival" period, with builders tirelessly working at the construction site.

During the National Day and Mid-Autumn Festival holidays, at the construction site of the Huajin Aramco Petrochemical and Raw Material Engineering Project in Panjin, Liaoning, construction workers are seizing the "golden September and silver October" peak construction period to speed up construction and ensure the progress of the project.

Recently, the construction project of the packaging industrial park of Shanxi Yamei Packaging Technology Co., Ltd. officially commenced. It is understood that the project has a total investment of 300 million yuan and covers an area of 160 acres. With the core concept of "green manufacturing and full-chain collaboration," it integrates three core segments: raw material research and development, intelligent printing, and finished product manufacturing. The project aims to build a vertical industrial chain from polymer new materials to end packaging products. It also focuses on six major functions, including intelligent manufacturing and research and development design, striving to create an integrated platform for the entire industrial chain, assisting Xiongshan Group in its transition from the traditional energy industry to advanced manufacturing.

After the project is completed and put into production, it will have an annual production capacity of 20,000 tons of high-barrier functional film new materials, new plastic packaging film materials, and polymer new materials, among other composite packaging products. It is expected to achieve an annual sales revenue of up to 500 million yuan and create over 100 jobs, injecting new vitality into the high-quality economic development of the Shangdang District.

On October 8, 2025, Guangdong Dongyue Chemical Technology Co., Ltd., a subsidiary of Huicheng Environmental Protection, successfully resumed production and achieved stable operation for its 200,000 tons/year mixed waste plastic resource utilization demonstration project.

After multiple rounds of optimization and transformation, the project team successfully advanced the resumption of production. Following the resumption, the unit quickly entered a stable operational state, and the light oil product from plastic pyrolysis met all standards according to third-party testing. It has been successfully delivered to customers in Quanzhou. This delivery marks a new phase in the market application of the 200,000-ton/year project, laying a practical foundation for the large-scale promotion of waste plastic resource technology.

03

Innovative Materials

Currently, the resource utilization rate of 865 million tons of crop straw in China is only about 1%, creating a significant gap between the enormous resource potential and the actual utilization. This gap provides a broad stage for industry innovators. Driven by both policy incentives and market demand, Shandong Taike Environmental Technology Co., Ltd. has become a benchmark for the implementation of the national bio-based materials strategy, leveraging its full industry chain layout, technological breakthroughs, and cross-regional collaboration.

The self-developed polylactic acid synthesis process has broken through industry bottlenecks: the bio-based content exceeds 92%, the material's heat resistance surpasses 120℃, and the impact strength exceeds 80 MPa. It has been successfully applied in high-end fields such as lightweight structural components for new energy vehicles and aerospace interior parts, promoting a carbon reduction rate of over 70% throughout the material's entire lifecycle, providing a Chinese solution for the global "dual carbon" goals.

Global leader in advanced materials and specialty chemicals, Solvay, has launched a new high-temperature grade of non-fluorinated surfactants (NFS) perfluoroelastomer (FFKM) product range. This innovative series is meticulously designed to provide exceptional sealing performance in the most demanding environments while supporting the semiconductor industry’s transition towards a more sustainable future.

Based on the tradition of scientific exploration, the latest fluorine-free surfactant perfluoroelastomer (FFKM NFS) from Sealsource offers a continuous working temperature exceeding 320°C, far surpassing the performance of traditional perfluoroelastomers. This new grade utilizes the latest developed high-temperature curing agent, providing unparalleled purity and reliability in high-temperature environments without the need for additional fillers.

On October 8, at the K Show in Düsseldorf, Germany, a leading global exhibition for the plastics and rubber industry, Covation Biomaterials LLC ("CovationBio®"), a biomaterials company, showcased its latest research and development achievements in the field of advanced bio-based materials innovation. They highlighted milestones and the latest progress of the CovationBio® bioPTMEG project. CovationBio® bioPTMEG is a bio-based alternative to fossil-based PTMEG, aimed at helping customers reduce their dependence on non-renewable materials. It also demonstrates excellent durability and elasticity in high-performance applications such as spandex, polyurethane, and thermoplastic elastomers.

04

Material Application

At the K 2025 exhibition in Düsseldorf, Covestro will focus on "The Material Effect" as its core theme: at booth A75 in Hall 6, showcasing over 25 innovative stories demonstrating how high-performance material solutions can help address the most pressing contemporary challenges. In line with the K 2025 conference theme "The Power of Plastics - Green·Smart·Responsible," Covestro presents a series of solutions that already combine more sustainable materials and processes with innovative expertise, which have been implemented in scalable applications and are suitable for mass production.

Genomatica (referred to as "Geno"), a leading company in industrial biomanufacturing technology, announced a new partnership with Sojitz Corporation, aimed at significantly accelerating the commercialization process of plant-based nylon 6 using Geno's proprietary technology. Sojitz Corporation will expedite the product launch cycle through strategic financial investment and contribute its expertise in commercial operations.

On October 6th, Costa Rica officially launched a new design for its physical identity cards. The new design aims to enhance security, increase usability, and protect personal data. The physical identity cards with the new design will be valid for 10 years.

The newly designed physical ID card uses a more durable polycarbonate material and colored laser engraving technology; the barcode on the ID card has been replaced by the MRZ (Machine Readable Zone), which allows automatic identity verification systems to read the document information.

【Copyright and Disclaimer】This article is the property of PlastMatch. For business cooperation, media interviews, article reprints, or suggestions, please call the PlastMatch customer service hotline at +86-18030158354 or via email at service@zhuansushijie.com. The information and data provided by PlastMatch are for reference only and do not constitute direct advice for client decision-making. Any decisions made by clients based on such information and data, and all resulting direct or indirect losses and legal consequences, shall be borne by the clients themselves and are unrelated to PlastMatch. Unauthorized reprinting is strictly prohibited.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track