[weekly new materials] global chemical recycling projects "large withdrawal"! polymer additive company rushes to go public

This week's industry highlights: In corporate developments, Huafon Chemical and Wanhua Chemical reported a decline in net profits, Celanese closed a plant but saw a net profit increase, Saperatec declared bankruptcy, and Nengzhiguang will apply for listing on the Beijing Stock Exchange; Kaizhong Precision plans to set up a factory in Thailand, and Hitachi plans to exit the white goods market.

In terms of production capacity, Dow has canceled the construction of a plant, PetroChina's facility has been handed over, and multiple projects have made progress. In the field of innovative materials, new products are emerging, and breakthroughs have been made in research and development. In the automotive sector, materials have new applications, and the Polyplastics Group will also showcase recycling technology at K 2025.

01

Company News

For the performance changes, Huafeng Chemical stated that in the first half of 2025, the company faced a complex and volatile external economic environment, with factors such as U.S. tariffs and geopolitical issues impacting the situation, leading to a weakening overall growth momentum. The spandex industry, in which the company operates, has experienced an oversupply, with product prices at historical lows and overall trends favoring volume over price. Both product prices and profits have been affected.

According to the news from Special Plastic World on August 14, German multilayer flexible plastic packaging recycler Saperatec has filed for bankruptcy.

The company will begin operating its first recycling plant in Dessau, Saxony-Anhalt, in May 2024. The facility has been under construction since 2022 and has an annual output of 17,000 tons. The project is funded by the state of Saxony-Anhalt and the European Union as part of the Horizon 2020 research funding program.

On August 13th, Ningbo Nengzhiguang New Materials Technology Co., Ltd. (stock code: 920056.BJ) officially launched its IPO on the Beijing Stock Exchange, with an issue price set at 7.21 yuan per share. This "small giant in polymer additives," backed by industry giants such as Kingfa Sci & Tech, BASF, and LG, entered the capital market with a P/E ratio of 11.28, attracting significant attention from the plastics industry.

According to reports, for this IPO, Neng Zhiguang plans to raise 107 million yuan, of which 81 million yuan will be used for the expansion project of functional polymer materials, and the remaining funds will be used for the construction of the R&D center. The implementation entity for the former is Ganzhou Neng Zhiguang. According to its public transfer prospectus for listing on the New Third Board, Ganzhou Neng Zhiguang is mainly responsible for the expansion of the company's plastic modification additives and biodegradable polymer materials projects, serving as a beneficial supplement to the parent company, and began production in 2020.

On August 13, Kaizhong Precision announced that in order to implement the strategic planning layout for its overseas connector and other precision component businesses, the company intends to invest in establishing a subsidiary in Thailand and constructing a new production base. The investment amount will not exceed 250 million RMB (or equivalent in other currencies), including but not limited to purchasing land, acquiring and constructing fixed assets, and related matters. The funding will come from the company's own funds and self-raised funds, with the actual investment amount subject to approval by the relevant authorities in China and the local area.

According to Japanese media reports, the comprehensive electric machinery giant Hitachi is currently considering selling its domestic white goods business, including core product lines such as refrigerators and washing machines. This is also Hitachi's last white goods business segment. The company has already approached several companies, including Samsung and LG, to explore acquisition interest. The transaction is expected to amount to between 100 billion and several hundred billion yen. If this transaction materializes, Hitachi will become the fourth Japanese giant, following Sanyo, Toshiba, and Sharp, to sell its home appliance business overseas.

Recently, a series of actions by specialty materials manufacturer Celanese Corp. has attracted widespread attention in the plastics industry.

On one hand, in the second quarter financial report released on August 11, Celanese's net profit increased significantly. On the other hand, the company announced the closure of its plant in Sarnia, Ontario, Canada. This plant primarily produces Vamac brand ethylene acrylic elastomers (AEM), known for their high-temperature resistance, oil resistance, and chemical corrosion resistance. These products are widely used in automotive seals, electronic insulation materials, and other plastic-related fields.

On August 11, 2025, Wanhua Chemical (600309.SH) released its semi-annual report, showing that the company achieved operating revenue of 90.901 billion yuan in the first half of the year, a year-on-year decrease of 6.35%; the net profit attributable to shareholders was 6.123 billion yuan, a year-on-year decrease of 25.10%.

The report card has attracted widespread attention and discussion in the chemical industry. As a benchmark enterprise in China's chemical sector, the performance fluctuations of Wanhua Chemical not only reflect the cyclical adjustments of the current chemical industry but also reveal the deeper logic of industry transformation.

02

Production Capacity Dynamics

Recently, Dow announced the cancellation of the construction project for Europe's largest chemical recycling plant. The plant was to be developed in collaboration with technology partner Mura Technology and was originally planned to be built at Dow's site in Böhlen, Germany, with an annual capacity of 120,000 tons. According to S&P Platts, the cancellation of this plan is due to Dow's decision to permanently close the steam cracker in Böhlen by 2027. The recycling plant was initially intended to provide a sustainable naphtha alternative (i.e., recycled feedstock) for the cracker. With the closure of the cracker, the economic prospects for the recycling plant also seem to have vanished.

On August 12, the PO/SM unit of the Guangxi Petrochemical Refining and Chemical Integration Transformation and Upgrade Project was successfully and thoroughly handed over with high quality.

The plant commenced construction on October 8, 2023, with the EPC contract awarded to Huanqiu Engineering Company. A consortium formed by Huanqiu Beijing Company and Huanqiu Six Construction Company will jointly execute the project, which is expected to be completed and delivered in 22 months. As China's first independently designed, procured, and constructed PO/SM plant, its commissioning will significantly reduce the capacity of the high-pollution chlorohydrin method for producing propylene oxide, lower import dependency, and further enrich the industrial chain in the South China and East China markets.

The Inner Mongolia Zhuozheng Coal Chemical Project is a large-scale modern coal chemical project invested and constructed by Inner Mongolia Huineng Holding Group's wholly-owned subsidiary. It is located in the Nalin River Industrial Park of the Sulige Economic Development Zone in Uxin Banner, covering a total area of approximately 7,500 acres, with an estimated total investment of 59 billion yuan. On the basis of the original project with an annual output of 1.2 million tons of methanol and 1 million tons of acetic acid, the overall project involves conducting on-site research and technical exchanges with 53 units including design institutes, process package patent holders, and production enterprises. In accordance with the national green, low-carbon, energy-saving, and environmental protection industry guidance policies, the project adopts advanced coal fractionation, efficient and clean comprehensive utilization technology, coupled with large-scale pulverized coal gasification, fixed-bed hydrocracking, the methanol-to-ethanol and formaldehyde-to-glycolate technology from Dalian Institute of Chemical Physics, and the polyglycolic acid technology from Shanghai Pujing, among other advanced technologies.

The project will be constructed in two phases and four stages, with an expected production capacity of 1,101,500 tons by 2027 and a total of 2.6 to 3.2 million tons of new material products by 2030.

Recently, the biodegradable materials industrial park project in Xun County, invested and constructed by Henan Techuang Biotechnology Co., Ltd., was officially put into operation. This marks a significant step forward for Xun County in the field of green and low-carbon economic development, injecting new vitality into the county's sustainable development.

It is understood that the project employs internationally advanced bio-fermentation and polymerization technologies to convert agricultural waste such as straw and corncobs into high-value-added products like fully biodegradable packaging materials and textile fibers. Currently, the products have been adopted in fields such as express delivery, supermarkets, catering, and agriculture, with leading companies like JD.com, SF Express, and Meituan using "Jun County Manufacturing."

As the world's largest supplier of BOPA (biaxially oriented polyamide film), Zhonglun New Material Co., Ltd. has made new moves once again. On August 11, news came from the construction site of Zhonglun New Material's new energy film material project located in Haicang that the civil engineering of the main building of Phase I has been successfully completed, and the project has entered the equipment commissioning stage. The project leader stated that the technical team is focusing on partial equipment commissioning, making every effort for the final sprint to put the new energy film production line into operation.

In the high-cleanliness dust-free workshop under debugging, a nearly 100-meter-long world-class new energy thin film production line has been installed in place. From the silo equipment in the feeding area, the melt extruder, to the precision chain clamps densely arranged in the stretching area, and on to the winding and slitting devices, the entire process is highly automated. This technologically advanced production line is expected to be put into operation in October this year and will be used to produce ultra-thin capacitor films. This is also an important initiative by Zhonglun New Materials to enrich its high-precision product matrix and enhance market competitiveness.

In the first half of 2025, Qingyang City produced 6.3217 million tons of crude oil and 4.8623 million tons of raw coal, while the city's power generation reached 4.376 billion kilowatt-hours. Qingyang is focusing on five key areas: increasing oil and gas reserves and production, green and intelligent coal development, comprehensive development and utilization of new energy, oil-coal-gas conversion, and improving the planning system. The city is vigorously promoting the integrated development of oil, coal, gas, wind, solar, thermal, and hydrogen energy, accelerating the construction of the energy chemical base. The implementation of various energy projects has equipped Qingyang's modern energy industry with wings to soar.

Under the blue sky and white clouds, vehicles and construction personnel are shuttling back and forth. At the construction site of the Qingyang Tongxin 500,000 tons/year light hydrocarbon deep processing project in the southern petrochemical industrial park of Qingyang City Xifeng Industrial Park, various main unit projects and the whole plant pipe gallery are being constructed simultaneously. The machinery is roaring, vehicles are shuttling, sketching a bustling scene of construction.

03

Innovative materials

Clariant launches new product to expand stabilizer production capacity in China.

To meet the growing global demand, Clariant has taken a strategic initiative to make significant progress in its stabilizer product portfolio by combining expanded production capacity in China with innovative applications to enhance performance in artificial turf applications and the medical field. This expansion aims to meet the increasing demand for high-quality stabilizers in Asia and globally. The joint venture between Clariant and Beijing Tiangang Auxiliary Co., Ltd. has successfully completed the chemical commissioning of the second S-EED production line at its Cangzhou plant in China. The new production line will primarily produce the multifunctional stabilizer Nylostab S-EED.

With the comprehensive implementation of Canada's single-use plastics ban, Canadian materials science company CTK Bio has launched an end-to-end solution platform aimed at assisting businesses in transitioning away from traditional plastics. According to the Canadian federal Single-Use Plastics Prohibition Regulations (SUPPR), products such as checkout bags, cutlery, straws, stir sticks, ring carriers, and polystyrene containers are now banned. CTK Bio states that its product line "provides a direct path to compliance," and the sustainable materials it has developed not only meet regulatory standards but also help achieve broader Environmental, Social, and Governance (ESG) goals.

As of August 12, it is reported that as modern engineering demands more from materials, they not only need to maintain their shape but also be lightweight, high-strength, high-temperature resistant, and possess good damage recovery performance. In industries such as aerospace, defense, and automotive, such materials mean safer vehicles, longer service life, and less environmental waste.

Researchers at Texas A&M University have recently made a significant step toward this goal. They have discovered new properties of an ultra-durable, recyclable plastic known as aromatic thermosetting copolyester (ATSP). This plastic not only can self-heal and regain its shape but also maintains its strength through repeated use. This discovery could set new benchmarks for reliability and sustainability in high-performance manufacturing.

On August 14, it was reported that researchers at the Georgia Institute of Technology successfully developed a new material inspired by seashells. This breakthrough is expected to revolutionize the application mode of recycled plastics, making them stronger, more stable in performance, and significantly reducing production costs. The research team selected recycled high-density polyethylene (HDPE) as the experimental material, which is commonly used as transparent stretch film for wrapping pallet goods. They cut this stretch film into thin pieces to serve as "bricks," and then layered them with a softer adhesive polymer "mortar" to mimic the structure of nacre. When testing this biomimetic material on a custom mechanical device, the results showed that it not only maintained the performance level of the original plastic but also reduced the volatility of a key performance indicator—the maximum elongation—by more than 68%.

Cortec has launched EcoWorks 100, a new packaging film that combines fully bio-based components with industrial compostability. The film is certified by Austria's TÜV (certificate number).#TA8012509046It is certified as an industrially compostable product and contains 100% USDA certified biobased content.

04

Material Application

Materi'act launches fiber-reinforced composites to enhance automotive visible parts.

Materi'act, a sustainable materials supplier, announced a breakthrough in sustainable biocomposite materials for injection molding processes in the automotive industry. Building on the success of their NAFILean-R material—a recyclable biocomposite made from recycled plastic and enhanced with 20% hemp fibers—the company has launched a new series of NAFILean Vision materials. The new material not only meets stringent performance standards but also enhances the visual texture by highlighting its biomass content. Materi'act, a sustainable materials subsidiary of Forvia (formerly Faurecia SE), a Tier 2 automotive systems supplier in France, stated that this new material sets a new benchmark for environmentally friendly and visually appealing automotive components.

The University of Michigan discovers 3D X-ray view of magnesium alloy for the first time, potentially revolutionizing lightweight automotive design.

Breakthroughs in materials science may help engineers design stronger, lighter, and more fuel-efficient cars. According to foreign media reports, researchers at the University of Michigan have used powerful X-rays to capture the 3D view of the internal microstructure of lightweight magnesium alloys for the first time, revealing how they absorb stress without fracturing. This discovery opens the door for the broader application of magnesium in the automotive industry, potentially reducing costs and enhancing performance.

This research, funded by the U.S. Department of Energy, provides new insights into the response of magnesium alloys under mechanical stress. Magnesium is 30% lighter than aluminum, and although some manufacturers have already used it for non-load-bearing components, its broader application has been limited due to its unpredictable behavior under stress. Understanding and controlling this behavior could make magnesium a mainstream material in automotive production.

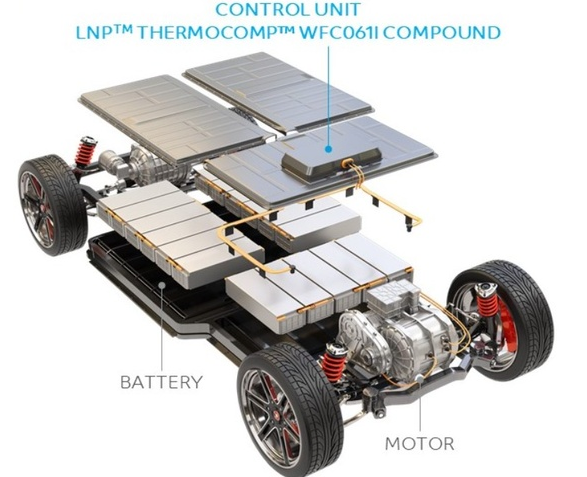

SABIC launches LNP™ THERMOCOMP™ non-halogenated flame retardant compound to enhance the safety performance of electric vehicle control units.

Global chemical industry leader SABIC recently launched a modified material, LNP™ THERMOCOMP™ WFC061I, which features excellent non-brominated/non-chlorinated flame retardancy (FR) and is designed to enhance the safety and functionality of key components like electric vehicle control units (EVCU). This new specialty material, which won the 2025 Edison Award, is especially suitable for manufacturing enclosures for various applications. With its outstanding structural performance, it effectively protects sensitive internal electronic components from fire/smoke, impact, moisture, and other potential threats.

On August 15th, Zhuanshu Vision reported that the Polyplastics Group will update its series of sustainability commitments at the upcoming 2025 K Show (Hall 7A/B02) to be held in Düsseldorf, Germany, from October 8th to 15th. The company will unveil new technologies aimed at reducing the global environmental footprint and accelerating the move towards a cleaner and healthier world.

Measures to promote the circular economy include setting two carbon emission reduction targets. By 2030, Daicel Group, including Polyplastics Group, plans to reduce its greenhouse gas emissions by 50% compared to 2018. The company also aims to reduce the cradle-to-gate Product Carbon Footprint (PCF) by 30% compared to 2018.

【Copyright and Disclaimer】This article is the property of PlastMatch. For business cooperation, media interviews, article reprints, or suggestions, please call the PlastMatch customer service hotline at +86-18030158354 or via email at service@zhuansushijie.com. The information and data provided by PlastMatch are for reference only and do not constitute direct advice for client decision-making. Any decisions made by clients based on such information and data, and all resulting direct or indirect losses and legal consequences, shall be borne by the clients themselves and are unrelated to PlastMatch. Unauthorized reprinting is strictly prohibited.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track