[Weekly New Materials] ExxonMobil Halts European Plastic Recycling Investment, Attends K Show with Multiple Giants Showcasing New Products

This week's industry highlights:

In terms of project developments, Dow Chemical's Path2Zero project may be delayed by 1-2 years; Tesla's German factory plans to increase production; Nordic NG and ABB have launched carbon dioxide-based plastic accessories; Nova Chemicals has reached an rPE supply agreement with a packaging company; BASF's high-performance materials plant in Europe has obtained REDcert² certification.

In terms of capacity and innovation, the ethylene transformation project at Lanzhou Petrochemical has commenced; Wanhua Chemical has added a production capacity of 200,000 tons/year for ABS; Kunlun Engineering has successfully launched a 3,000 tons/year hydrogenated bisphenol A unit; Arkema will showcase sustainable polymer technologies at K2025; SMX and REDWAVE are collaborating to establish certification standards for recycled materials.

For more industry updates, please stay tuned for this week's [Weekly New Materials Plastics Delivery].

01

Company News

During a speech at the recent Morgan Stanley 13th Annual Laguna Conference, Dow Chemical CEO Jim Fitterling stated that due to market adjustments, the company's Path2Zero integrated polyethylene (PE) project in Alberta may face further delays.

Dow Chemical has recently suspended construction of its $11.6 billion net-zero emissions petrochemical project located northeast of Edmonton due to economic uncertainty. Fitterling stated this week that the construction of the project will be delayed until market conditions improve, with an update expected by the end of the year. "We have announced a one-year delay for the project. Currently, the delay period could be between 1 to 2 years."

André Thierig, the manager of Tesla's factory in Gruenheide near Berlin, told the German Press Agency (DPA) that due to strong sales performance, Tesla plans to increase production at the factory for the remainder of this year.

Nordic NG Company collaborates with ABB to launch the world's first carbon dioxide-based plastic electrical accessories.

NG Nordic has teamed up with ABB Oy, Wiring Accessories, Porvoo, a subsidiary of the ABB Group, to launch the world's first electrical accessory product made from carbon dioxide-based plastic.

Nova Chemicals Corp., headquartered in Calgary, has reached a long-term supply agreement with Chicago-based packaging manufacturer Charter Next Generation (CNG). Nova Chemicals will supply post-consumer recycled polyethylene (rPE) resin, derived from recycled films and plastic packaging, to be sold under Nova's Syndigo brand name.

Nova Chemicals stated that this material offers a lower-emission alternative compared to virgin polyethylene. Currently, Syndigo, produced at Nova's new facility in Connersville, Indiana, is being integrated into CNG's operations.

5. BASF's high-performance materials European factories have all obtained REDcert² certification.

Following the transition to renewable electricity at all its European sites in January 2025, BASF's Performance Materials Division announced on September 15 that all its production sites have obtained REDcert² certification. This certification is an authoritative system in the field of sustainable raw material usage in the chemical industry. With the recent successful certification of BASF's polyurethane production site in Malacky, Slovakia, the division can now offer certified quality balance solutions to customers through its ten facilities.

Alexander Weiser, Head of BASF's Performance Materials in Europe, stated: "At BASF, we are not only about proposing ideas; we are committed to delivering tangible results. This certification is another milestone in our 'Plastics Journey' towards sustainability, demonstrating our firm commitment to sustainability and circularity in the plastics sector. With this, we are ready to meet our customers' current and future demands for sustainable solutions."

Zeon Corporation announced adjustments to its COP plant plans in Japan! The investment amount has increased to 3.78 billion yen.

Zeon Corporation announced an adjustment to the investment plan for its cyclo olefin polymer (COP) plant located in Shunan City, Japan, increasing the total investment amount from the previously estimated 70 billion yen to 78 billion yen (approximately 3.7839 billion RMB).

The company stated that the increase in investment is due to the rising costs of labor, materials, and equipment, which are expected to lead to higher construction costs. Reon Corporation pointed out that the adjusted investment amount includes both confirmed cost increases and anticipated future expenditures. To raise this investment, the company plans to combine internal funds with loans from financial institutions. The new factory is expected to be completed in the first half of the fiscal year 2028, so Reon Corporation believes that this investment will have a minimal impact on its consolidated earnings for the fiscal year ending March 31, 2026.

Niche Polymer has acquired four resin powder plants in the United States from LyondellBasell Industries, with the purchase amount undisclosed. The company has established a new business division, Specialty Powders LLC, to manage the expanded powder manufacturing operations. This strategic acquisition enhances Niche Polymer's production layout and product portfolio in the specialty powders sector, based in Ravenswood, West Virginia. Previously known for its custom composite business in thermoplastic engineering resins, the company will now leverage LyondellBasell's mature powder technology—capable of precise particle size control and customized formulations—to deliver stable, high-performance products.

Sonoco, an American packaging group, has sold its ThermoSafe business unit to New York-based private equity firm Arsenal Capital Partners for a total transaction value of $725 million (equivalent to €619 million). The transaction includes a base acquisition price of $650 million, along with an additional $75 million contingent on this year's earnings. The transaction is expected to be completed by the end of 2025, and Sonoco plans to use the net proceeds from the transaction to repay debt.

ExxonMobil suspends $118 million plastic recycling investment in Europe, with EU policy disputes as a key obstacle.

U.S. energy giant ExxonMobil (XOM.N) has suspended its 100 million euro (approximately $118 million) investment plan in the European plastic recycling sector due to disputes over the proposed EU regulation draft's standards for the "recycled material content in end products."

The company originally planned to deploy two chemical recycling projects at its existing petrochemical plants in Rotterdam and Antwerp, with an annual processing capacity of 80,000 tons of plastic waste. However, Senior Vice President Jack Williams revealed in an interview that these two projects have currently been put on hold. He pointed out that the EU draft links the calculation method of recycled material content directly to the "mass of waste input" and the "mass of finished product output." This rule essentially "discriminates" in favor of independent recycling facilities rather than integrated petrochemical plants with fossil feedstock supply. Williams emphasized, "Apart from policy factors, all other conditions are ready—we have local support and are eager to advance the investment, but EU policy has become the only obstacle."

02

Capacity Dynamics

Recently, the construction of Zhonglu Company's No. 1 loading and unloading facility and its peripheral supporting projects has commenced, marking a critical phase of full acceleration and comprehensive advancement in the ethylene transformation and upgrading supporting project of Lanzhou Petrochemical.

The project utilizes raw materials such as styrene, butadiene, methyl methacrylate, and butyl acrylate produced by the integrated ethylene project at Wanhua Yantai Industrial Park, employing Wanhua's self-developed, proprietary emulsion grafting-in-situ SAN blending process to produce ABS and ASA. Upon completion, the production will include 200,000 tons/year of general-purpose ABS materials and 20,000 tons/year of ASA materials.

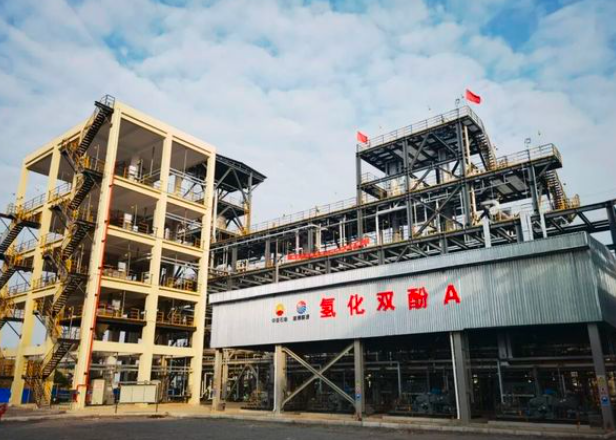

Recently, the first 3000-ton/year continuous hydrogenation bisphenol A unit, developed and designed by Kunlun Engineering, was successfully launched at Puyang Shengtong Juyuan New Materials Co., Ltd., with product quality indicators reaching international leading levels. This technology adopts a continuous hydrogenation process developed by Kunlun Engineering, featuring a simple process flow and high product purity. It also allows for flexible adjustment of different isomer ratios, showcasing originality and novelty.

On September 15th, the environmental impact assessment document for the relocation project of Suzhou QuanHua Biomaterials Co., Ltd.'s annual production of 400 million sets of biodegradable material tableware was accepted for public announcement.

Suzhou Quanhua Biomaterials Co., Ltd. was originally located at No. 8, Building 3, Mu Xu East Road, Mudu Town, Wuzhong District, Suzhou. Due to the company's development needs, it now plans to invest 43 million yuan to relocate to No. 28, South Guandu Road, Yuexi Street, Wuzhong District, Suzhou. The company will lease the plant of Suzhou Xingquanhua Bioplastics Co., Ltd. for production and operation activities. The leased area covers 26,746.9 square meters, and after completion, it will form a production capacity of 400 million sets of biodegradable tableware per year.

The petrochemical downstream and extended industrial chain project of Shandong Yulong Petrochemical Co., Ltd. relies on the basic chemical raw materials produced by the Yulong Island Refining and Chemical Integration Project (Phase I), including ethylene, propylene, butadiene, xylene, benzene, toluene, ethylene oxide, styrene, ethylene glycol, PX, etc. This project involves the construction of downstream petrochemical deep processing units and industrial chain extensions to produce various high value-added new materials and chemicals. A total of 56 production units, utility engineering facilities, auxiliary engineering facilities, and production roads will be constructed.

03

Innovative Materials

Arkema to showcase cutting-edge polymer solutions and technologies at K 2025.

Arkema will showcase at K2025, the world's leading trade fair for plastics and rubber, held in Düsseldorf this October. Under the theme "Innovating for a Sustainable Future," Arkema will focus on presenting its cutting-edge solutions and technologies to address the major trends shaping the global industry.

At K2025, Arkema will showcase innovations focused on five key strategic areas, highlighting the group's commitment to advancing sustainability and meeting the evolving demands of the global market. The company will also present its latest innovations in high-performance polymers, marking an important milestone this year—including the expansion of Kynar® PVDF production capacity in the United States, the launch of a new brand Zenimid™ for ultra-high-performance polyimide series, and a significant investment in the Rilsan® Clear transparent polyamide facility in Singapore, which will double its global capacity and is set to be operational in the first quarter of 2026.

HolyPoly invites guests to the 2025 K Show to join a "time travel" journey in the iconic DeLorean DMC-12 from the movie "Back to the Future." Through this creative approach, the company aims to draw public attention to an urgent and pressing issue: the shortage of high-quality recycled plastic materials.

During the K fair in 2025, visitors can experience a "time travel" ride in a DeLorean DMC-12 at the booth of HolyPoly GmbH, a company widely known from the movie "Back to the Future." This German startup seems to have "returned" from the future, bringing with it an achievement that has yet to be realized: a stable supply of high-quality, cost-effective post-consumer recycled materials. "We offer booth visitors an opportunity to 'travel' to 2035," said Matthias Röder, HolyPoly's marketing manager. "They will look back at the next decade through the 'rearview mirror of history' — such an experience may change their perception of the present."

Global supply chain solutions company SMX has announced the signing of a letter of intent with REDWAVE Technology Center, a subsidiary of BT-Systems, to integrate molecular traceability technology into industrial recycling systems. This collaboration aims to combine SMX's molecular tagging and blockchain verification technology with REDWAVE's sorting detection systems, creating a recycling process that can both separate materials and provide real-time certification of their origin and composition.

According to the press release, the collaboration focuses on three main objectives: embedding SMX traceability technology into the REDWAVE platform, ensuring that recycled materials comply with re-entry into the supply chain, and establishing industry standards for recycled material certification. The two parties plan to achieve technical synergy through joint industrial deployment and large-scale system integration.

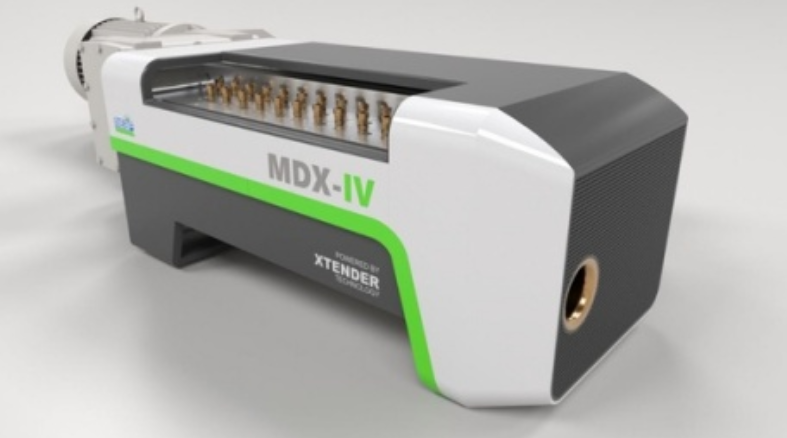

MEAF showcases Xtender technology at the 2025 K Show in Germany, with two new devices aiding in the quality enhancement of recycled materials.

At the 2025 K Show in Germany (International Trade Fair for Plastics and Rubber), Dutch manufacturer MEAF Machinery will launch two new equipment series aimed at enhancing the quality of recycled materials — the MDX-IV series and the MDX-DEO series. Both of these devices are based on the company's patented Xtender melt conditioning technology.

04

Material Application

Saudi Basic Industries Corporation (SABIC) will showcase at the 2025 PCIM Asia exhibition, located at booth F03 in Hall N5, highlighting its ultra-thin ELCRES™ HTV150 dielectric film.

The film is highly suitable for capacitors in demanding electrical applications, including AC-DC inverters for electric vehicles (EVs). High-end capacitors made with this film from SABIC can operate in high-temperature environments up to 150°C, with minimal derating of the applied voltage (V).

Syensqo has launched a new medical-grade Amodel® polyphthalamide (PPA). This glass-filled polymer is designed for advanced disposable medical devices, featuring excellent heat resistance, strong electrical performance, and key biocompatibility requirements for limited contact time medical applications.

Amodel® PPA has a melting point exceeding 300°C and maintains mechanical strength at temperatures up to 280°C. These characteristics make it highly suitable for demanding manufacturing processes such as Surface Mount Technology (SMT) assembly, infrared (IR) reflow soldering, and metal overmolding. This material is particularly suitable for electrosurgical instruments and electronic device assembly, where complex injection molding geometries offer advantages over other materials.

BASF's Intermediate Business Unit announced that its standard-grade amine product portfolio will soon be produced using 100% renewable electricity from the integrated production site in Geismar, Louisiana. This transformation plan is expected to begin in the fourth quarter of 2025 and continue into 2026, complementing the ongoing transitions in Europe.

Renewable electricity will be applied to the production of the amine product portfolio at the Geismar integrated production site through the use of solar and wind renewable energy credits. This transformation reflects BASF's overall strategy to achieve its 2050 net-zero emissions target, while ensuring product quality and supply continuity. By utilizing renewable energy credits and optimizing production processes, BASF's Intermediates division is significantly reducing the product carbon footprint (PCF) of its amine product portfolio.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track