Wanhua chemical key unit resumes production! q2 financial reports of chemical giants like basf show decline!

This week's industry highlight: Several key units at Wanhua Chemical's Fujian Industrial Park have resumed production.TDI production capacity leads the world; the global plastic additives market is set for expansion, and Liaoning Xinyuan Composite Materials Co., Ltd. is emerging; New Changan Automobile Group is drawing up a grand blueprint with the goal of achieving a production and sales volume of 5 million units by 2030, aiming to rank among the global top ten. Meanwhile, financial reports from chemical giants like BASF show declining performance in the second quarter, Binhu Chemicals is planning to list in Hong Kong, and Rebecca is under investigation for information disclosure violations.

In terms of production capacity, GuangdongThirteen key chemical projects highlight the advantages of clustering, with companies such as Lin'an Urban Investment Group, Anhui Huayang, and Ningbo Juhua advancing the construction and commissioning of new projects. Zhongjing Petrochemical's world's largest alkane integration base has also been put into operation.

Innovative materials and application fields, Amcor.Origin, along with companies like Hordijk and Kyoraku, is actively developing new products, while Toyota, Kreyenborg with infrared technology, and Vanden Global have also made new advancements in the application of sustainable materials.

Company News

1、36,000 tons of TDI capacity strongly resumes production! The price surge is expected to boost Wanhua Chemical's profits significantly.

Wanhua Chemical has released the latest announcement stating that its Fujian Industrial Park...The 800,000-ton/year MDI unit, the 360,000-ton/year TDI unit, and the 400,000-ton/year PVC unit have completed maintenance and resumed normal production.

As the world's largestWanhua Chemical, a producer of MDI and TDI, has a "giant" capacity layout: by the end of 2024, its annual TDI capacity will reach 1.11 million tons, accounting for nearly 30% of the global total capacity. After the second 330,000 tons/year TDI project in Fujian is put into operation in 2025, the total capacity will rise to 1.44 million tons/year. The TDI facility in the Fujian Industrial Park, which has been restarted, is one of the key nodes in its global supply chain.

The global plastic additives market is set to reach 650 billion! This company from Liaoning has already prepared its "trump card" product.

With the rapid development of the global plastics industry, the plastic additives market has also ushered in unprecedented growth opportunities.The global plastic additives market size in 2023 is approximately 58.12 billion USD (about 416.3 billion RMB), and it is expected to reach 90.69 billion USD (about 650 billion RMB) by 2033, with a compound annual growth rate of approximately 4.55%.

Plastic additives not only optimize the processing performance of plastics, significantly enhancing their strength, toughness, heat resistance, and corrosion resistance, but also include special functional additives such as flame retardants, antibacterial agents, and antistatic agents. These additives endow plastics with new application values and further expand their application fields. Among the many enterprises dedicated to the research, production, and sales of plastic additives, Liaoning Xinyuan Composite Material Co., Ltd. has secured a place in the industry with its high-quality products, professional services, and technological innovation.

3. Targeting a production and sales scale of 5 million vehicles by 2030, the new Chang'an aims to rank among the top ten global automakers.

On July 30th, the leadership team of China Changan Automobile Group Co., Ltd. made their first collective appearance. This new central state-owned enterprise, approved by the State Council and with the State-owned Assets Supervision and Administration Commission directly fulfilling the responsibilities of the investor, announced its strategic ambition to the world on the second day of its establishment — to build a world-class automobile group with global competitiveness and independent core technologies.

The establishment of China Changan Automobile Group is beneficial for accelerating the development of a globally competitive world-class enterprise and better supporting the high-quality development of the intelligent connected new energy vehicle industry. It aids Changan in integrating relevant resources to forge a new path in the fierce market competition and to open up new horizons, further strengthening, optimizing, and expanding state-owned enterprises. It also enables Changan to better participate in international competition, creating an international, market-oriented, professional, and youthful organization and team, thereby accelerating its progress towards becoming a world-class automobile brand.

Q2 Earnings Reports Are Here! How Did BASF, Dow, and Honeywell Perform?

Amid the intertwined backdrop of global economic fluctuations and geopolitical conflicts, the supply-demand imbalance challenges in the chemical industry have intensified. Recently, global chemical giants such as BASF, Dow, and Honeywell have successively announced...In the second quarter 2025 financial reports, how did each company perform? Which products were profitable? What important industry information was revealed?

On July 30th, BASF Group released its financial data for Q2 2025 and its full-year outlook. According to the financial report, the company's sales for this quarter amounted to 15.8 billion euros, a decrease of 342 million euros compared to the same period last year, representing a decline of 2.1%. Net profit plummeted by 81.6% year-on-year, amounting to only 79 million euros (compared to 430 million euros in the same period last year).

The chemical business continues to drag down overall performance, particularly the petrochemical department, which is significantly affected by oversupply, resulting in a year-on-year decline in chemical sales.The profit pressure in the basic chemicals business segment is evident, with earnings before interest, taxes, depreciation, and amortization excluding special items decreasing by 185 million euros compared to the same period last year, to 1.8 billion euros. The profit margin fell from 12.1% to 11.2%.

5. Revenue and net profit surge in Q1 2025! Leading chemical company goes public in Hong Kong.

On July 29, 2025, Binhu Chemical Co., Ltd. (601678.SH), a leading domestic chlor-alkali chemical company, announced that it is planning to issue H shares overseas and list them on the Hong Kong Stock Exchange. At the same time, the company is discussing specific advancement work related to this H share listing with relevant intermediaries, and details have yet to be determined.

Binhua Co., Ltd. was established inThe company, which was listed on the Shanghai Stock Exchange in 2010, was founded in 1968. It has five major business divisions: chlor-alkali, petrochemicals, specialty chemicals, new materials, and new energy. It is the largest supplier of propylene oxide and oilfield additives in the country, the largest domestic supplier of trichloroethylene, and an important producer of caustic soda products.

Caustic soda is widely used in light industry, chemical industry, textile, metallurgy, medicine, petroleum, and other industries. According to statistics, as of...By the end of 2024, China's total caustic soda production capacity will amount to 50.1 million tons. Among this, Binhua Co., Ltd. has a caustic soda production capacity of 610,000 tons, ranking at the forefront within Shandong Province. Meanwhile, Binhua Co., Ltd. is the largest granular caustic soda producer in China, and its flake caustic soda production capacity holds a leading position within Shandong Province.

6. The Wig Tycoon Harvests 900 Million Market Value, with the CSRC Penalty Revealing a Trillion-Yuan Blue Ocean in Plastic Wigs

Special VisionOn July 28th, it was observed that over the past weekend, an announcement thrust "Wig King" Rebecca (SH600439) into the spotlight. This wig giant, with a total market value of 4.188 billion yuan, is under investigation by the China Securities Regulatory Commission for alleged violations of information disclosure laws.

The announcement shows that Rebecca and its controlling shareholder Henan Rebecca Holding Co., Ltd. failed to disclose related-party non-operating fund transactions, insufficient provision for inventory write-downs, and poor management of insider information, among five major issues, exposing deep-seated risks in the company's governance. Just two months ago, Rebecca was penalized for failing to disclose in a timely manner.In 2024, the performance forecast was warned by the Henan Securities Regulatory Bureau, and the annual net profit attributable to the parent company was a loss of 118 million yuan, further exacerbating the predicament of its first loss in 25 years.

Production Capacity Dynamics

1. Thirteen key chemical projects revealed! Huizhou, Guangzhou, and Jieyang are going full throttle! An overview of Guangdong's petrochemical industry cluster.

Guangdong is an important economic province in China and is also in the top tier of the national petrochemical industry. "Vanguard", holding five major integrated refining and chemical bases in Guangzhou, Huizhou Daya Bay, Zhanjiang Donghai Island, Maoming, and Jieyang Dapeng Bay, and 24 chemical parks. In 2024, the refining capacity will reach 87.75 million tons per year (third nationwide) and ethylene capacity will be 5.17 million tons per year (second nationwide). Over 9,800 large-scale petrochemical enterprises generate 2.02 trillion yuan in revenue. Guangdong connects its 4,100-kilometer coastline with mega ports like Guangzhou Port and Zhanjiang Port, leading the nation in raw material import and product export costs. Moreover, as a key point of the "Belt and Road Initiative," it attracts global giants such as BASF and ExxonMobil to settle, continuously unleashing the innovative vitality of private chemical companies. Below are the latest developments of some benchmark projects.

2. Lin'an City Investment Group invests 1 billion to construct a renewable resource recycling project.

According to Zhang Wei, the Minister of the Urban Investment Engineering Management Department, the preliminary procedures for this project have been completed. The project was fully completed in June and smoothly commenced under the principles of high standards and high efficiency. The project has now entered the full construction phase, with site leveling and temporary facility setup successfully completed. The construction team is working diligently on the foundation and main structure to ensure completion by the end of January 2027 as scheduled. Once completed, the project will feature nine production lines and will broadly cover the production of building materials, sand washing from construction waste, solidified soil processing, and the sorting and recycling of waste plastics, household appliances, textiles, etc. Notably, the District Urban Investment Group will employ fully intelligent and environmentally friendly equipment, integrating green energy applications and digital twin technology, as well as establishing a digital ERP platform. This is aimed at creating a comprehensive circular economy industrial cluster that combines intelligent recycling and sorting, high-value processing and utilization, and the production of new building materials from solid waste resources. This will inject strong momentum into the reduction, harmlessness, and resource upgrading of solid waste disposal in the entire region of Lin'an District. After production starts, the annual output value is expected to reach 1 billion yuan.

The total investment is 350 million! The first phase of the Anhui Huayang Green Degradable, Recyclable, and Functional Fabric Project has been completed and put into operation!

On July 29, it was reported that the first phase of the Anhui Huayang Technology Co., Ltd. green degradable, recyclable, and functional fabric smart factory project has been completed and put into production.

The Anhui Huayang functional fabric project is located in Yuhui District, Bengbu City.In March 2024, a formal agreement will be signed, with a total investment of 350 million RMB, covering an area of 170 acres. Relying on internationally leading intelligent and automated dyeing and finishing equipment, the focus will be on providing one-stop solutions from fabric to garment for globally renowned clothing brands. Currently, the company's clients include domestic and international outdoor brands such as Li-Ning and Toread. Once the project is fully completed and operational, it will have an annual production capacity of 98 million meters of functional fabric, with an expected annual output value of 1.2 billion RMB and an annual tax contribution of 40 million RMB, further enhancing its market share in the high-end textile materials sector.

4. Ningbo Juhua's Ethylene Oxide Method for PDO Production! 150,000 Tons of Specialty Polyester Soon to be Commissioned

The South Plant of Ningbo Juhua Chemical Technology Co., Ltd.The 150,000-ton-per-year specialty polyester new materials project is scheduled to start production in the first half of the year.

After the project is put into production, it is expected to generate additional annual sales revenue.With an investment of 2.5 billion yuan, not only can it break the long-term technological monopoly of foreign countries in the polyester field and achieve full industry chain localization, but it also holds the promise of making a significant contribution to the independent controllability of China's special materials industry chain.

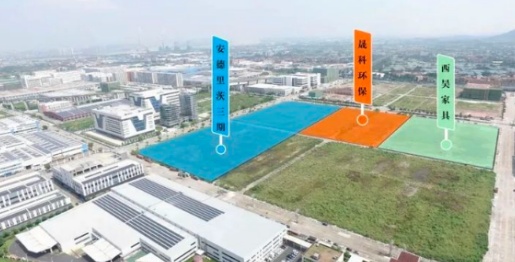

The foundation-laying ceremony for the Shengke Environmental Protection Resource Recycling Intelligent Equipment Production Base, with a total investment of 200 million yuan, was held in Foshan.

On July 26th, the groundbreaking ceremony for the Shengke Environmental Protection Resource Recycling Intelligent Equipment Manufacturing Base, with a total investment of 200 million RMB and a planned area of 40 mu, was held in the Lingang International Industrial Community. This adds a new force to the green intelligent manufacturing industry in Nanhai, Jiujiang! On the morning of the ceremony, Chen Haobin, Director of the Standing Committee of the Nanhai District People's Congress, along with a group of district and town leaders, participated in the groundbreaking for the Shengke Environmental Protection Resource Recycling Intelligent Equipment Manufacturing Base project.

It is reported that the investor, Guangdong Shengke Environmental Protection Technology Co., Ltd., has been deeply involved in the field of solid waste resource recycling equipment for many years.The project, recognized as a "High-tech Enterprise" and a "Specialized and New Enterprise of Guangdong Province," is being established in the Lingang International Industrial Community of Jiujiang Town. With a total investment of 200 million RMB and covering an area of approximately 40 mu, it will focus on the fields of plastics, metals, and electronic waste. The project aims to create a comprehensive base integrating the research and manufacturing of professional solid waste recycling equipment and production lines, along with the development and promotion of environmental protection technologies.

The world's largest alkane integration production base by Zhongjing Petrochemical, with a total investment of 30 billion yuan, has officially commenced operations.

On July 27, 2025, the Zhongjing Petrochemical Technology Park in the Jiangyin Port Economic Zone of Fuzhou City, Fujian Province, was adorned with colorful flags and a lively atmosphere as the world's largest alkane integrated production base of Zhongjing Petrochemical held a grand completion and commissioning ceremony. The completion of this milestone project signifies a crucial step forward in Zhongjing Petrochemical's development towards integration, scaling, intensification, and greening. With the world's largest single-plant production capacity, it reshapes the competitive landscape of the global alkane industry chain.

Innovative materials

Amcor develops lightweight polypropylene caps for household products.

Amcor has developed a polypropylene product for household use.The PP bottle cap combines a unique design with a lightweight construction, helping brands enhance visual appeal while supporting sustainability commitments. Amcor states that this new "Hector Child-Resistant Closure (CRC)" weighs only 7.25 grams, making it one of the lightest caps on the market, significantly saving materials and reducing carbon dioxide emissions. Compared to the traditional 14-gram caps, an order of one million Hector caps can reduce plastic usage by 6.75 tons.

2、Origin collaborates with Hordijk to produce sustainable PET caps on a large scale in Europe.

Origin Materials and Dutch packaging manufacturer Royal Hordijk Packaging have announced a strategic partnership to mass-produce polyethylene terephthalate (PET) bottle caps, marking an important step in promoting circular packaging solutions in the European market.

3. Kyoraku's tableware uses BASF's PESU.

Tokyo Kyoraku, a Japanese plastic products manufacturer, is now using BASF's specialty plastics. Ultrason® has added a unique dinnerware design concept to its comprehensive home goods product portfolio. It is called Amberware, made from Ultrason® E 3010 NAT, an injection molding and extrusion polyethersulfone (PESU) with higher toughness and high chemical resistance.

Material Application

Toyota Tsusho's ASR-derived recycled plastic has been adopted for use in Toyota's front fenders.

Toyota Tsusho Corporation announced that its group company K.K. PlaniThe ASR (Automobile Shredder Residue) derived recycled plastic manufactured by Planic has been used for the first time in Japan for the front fender seal of Toyota's Crown "Sport". Planic is a recycled plastic manufacturing company in Japan, jointly owned by Toyota Tsusho and Kojima Industries Corporation (a member of Kojima Industrial Corporation Group). The raw materials for recycled plastic used by Planic are collected from Toyota Metal Co., Ltd., a Toyota Tsusho Group company engaged in automobile recycling, as well as from ASR recycling facilities and home appliance recycling plants across Japan. Since the collected plastic containing ASR-derived plastic is difficult to classify by material, it is challenging to achieve car-to-car recycling with high-quality requirements, and thus the plastic is mainly incinerated (thermal recovery). In this situation, Planic became the first company in Japan to introduce advanced gravity separation technology and equipment, which has been practically applied in Europe, to achieve the production of high-quality recycled plastic and car-to-car recycling. This has become a major advantage for the company.

The European Food Safety Authority has approved Kreyenborg's infrared technology for use in food packaging recycling materials.

European Food Safety Authority (EFSA)The European Food Safety Authority (EFSA) has issued a positive "scientific opinion" on the infrared technology IR-Clean from the German company Kreyenborg, based on EU Regulation 2022/1616. This technology can decontaminate recycled polyethylene terephthalate (PET) flakes, enabling them to be used in the production of food packaging.

Kreyenborg announced that with the approval of its process by the EFSA, its IR-Clean system will be assigned a unique Recycling Authorization Number (RAN) and included in the public register.

Kreyenborg stated that multiple IR-Clean processes have received positive feedback from customers according to the old EC 282/2008 regulation. The company also added that with the new EU 2022/1616 regulation, the approval procedures for Kreyenborg and its packaging industry customers will be streamlined and simplified.

3. Vanden Global Launches New Catalog of Recycled PET Resins and Flakes

Plastic recycling companyVanden Global has launched a new catalog of recycled PET resins and sheets, which the company claims can provide manufacturers with a stable supply of high-quality recycled polyethylene terephthalate (rPET) materials.

The company, headquartered in the UK, stated:"As the demand for food-grade rPET and technically verified recycled materials continues to grow, Vanden's latest catalog showcases a full range of flakes and pellets certified by the European Food Safety Authority (EFSA), the U.S. Food and Drug Administration (FDA), and RecyClass, while also offering customized raw material solutions." The company also added that the launch of the new catalog demonstrates its ability to consistently and stably supply materials through its global presence, local expertise, and internal logistics network.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track