Using Three Different Sized Twin-Screw Extruders to Understand the Importance of Specific Mechanical Energy in Process Scale-Up

Introduction: The commercialization of a product involves several steps, including conception, design, development, laboratory-scale demonstration, application testing and performance, pilot-scale verification and validation, and finally production-scale certification. Products produced through twin-screw extrusion also need to follow this workflow, and a critical step for their successful commercialization isBridging the gap between laboratory scale and production scale. To this end, conducting medium-scale process studies is beneficial, as it allows for a better understanding of the limitations of a particular process.

This article demonstrates how to useCompare mechanical energyThe scale-up production process involves preparing masterbatch using polyolefin resin and three additives. All raw materials are fed through the extruder's feed port (barrel 1). The diameters of the laboratory, pilot, and production scale TSE are respectively26mm, 40mm, and 92mmIn addition, the extruder is co-rotating, fully intermeshing, parallel, and has a similar screw configuration (length-to-diameter ratio of 44, outer diameter to inner diameter ratio of 1.55).

Laboratory-scale compounding was carried out on a 26 mm TSE.

The masterbatch was initially produced on a laboratory scale using a 26mm TSE. The development of the compounding process for new products typically requires multiple iterations to determine the optimal process variables, including screw design, throughput, screw speed, and temperature profile, to ensure consistent and reliable operation and to produce products that meet specific quality requirements. Once these parameters are established, they can serve as a reference for scale-up production.

Under optimized processing conditions, the produced masterbatch pellets have an SME of 0.083 kWh/kg. Source (all images): C. Escobar

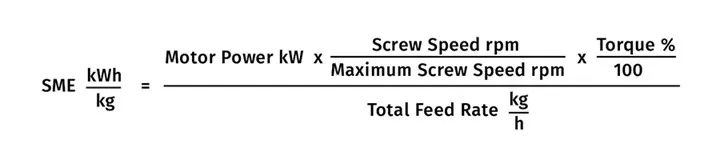

A key parameter for scaling up TSE is the Specific Mechanical Energy (SME) input. SME refers to the energy per unit mass transmitted from the extruder drive motor through the screw to the compound being processed, and it also affects the performance of the final product. Therefore, matching SME also helps ensure product quality.

The SME of the process can be estimated using Formula 1. In this 26 mm case, the SME of the masterbatch mixed using optimized process variable values is 0.083 kWh/kg. Figure 1 shows a photo of the optimized masterbatch pellets.

Conducting pilot-scale compounding using a 40mm TSE.

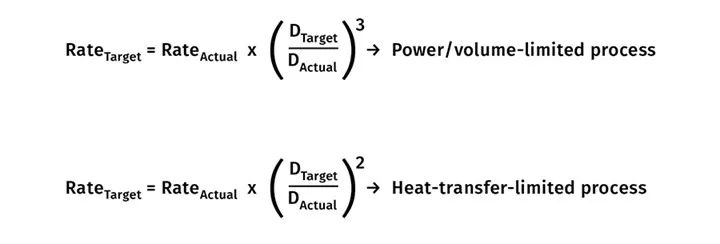

There are two extremes regarding the achievable rates in scale-up production of twin-screw extrusion processes. If the scaled-up extruder is limited by power/volume, the maximum rate can be estimated by the cube of the extruder diameter ratio, as shown in Equation 2. If the scaled-up extruder is limited by barrel wall heat transfer, the maximum rate can be estimated by the square of the extruder diameter ratio, as shown in Equation 3.

These scaling rules apply to extruders with screw combinations of similar geometry. In these formulas, D represents the extruder diameter, and "target" and "actual" refer to the extruder sizes to which the process will be scaled and the extruder size used to develop the process, respectively. For example, the "target" D is 40 mm, and the "actual" D is 26 mm.

The initial scale-up process for the 40 mm TSE adopted the same process conditions as the 26 mm TSE (optimized screw design, temperature profile, screw speed, etc.). Since there was no evidence indicating heat transfer limitations in the 26 mm TSE, the corresponding scale-up factor was estimated using Equation 2.

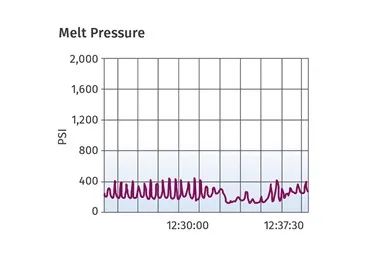

The initial compounding process with the 40 mm TSE exhibited significant and frequent pressure fluctuations, making the process unsustainable and unreliable, and also resulting in a marked decline in masterbatch quality. Therefore, process adjustments were made for optimization. After adjusting the process variables, the SME for masterbatch compounding was 0.055 kWh/kg (approximately 34% lower than the SME of the 26 mm TSE).

Figure 2A shows the pressure response over time during the initial compounding process on a 40 mm TSE, using the optimized variables obtained during process development on a 26 mm TSE.

Figures 2A, 2B, and 2C respectively show the initial pressure response, the adjusted pressure response, and the masterbatch obtained after optimization. Figures 2A and 2B display the variation of process pressure over time. In the initial stage (Figure 2A), the process pressure exhibits significant and frequent fluctuations over time.

Figure 2C shows the segregation and poor mixing of masterbatch components. Figure 2B shows the change in pressure over time after adjusting the temperature profile, screw speed, and rate.

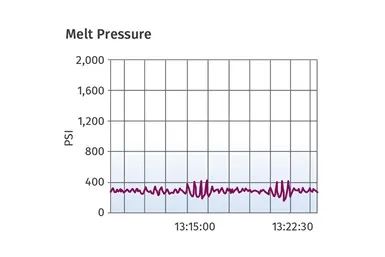

After adjusting the temperature profile, screw speed, and feed rate, the pressure response became more stable; however, significant short-term fluctuations still occurred over time, as shown in Figure 2B. Although the pressure response improved, the quality of the masterbatch deteriorated significantly, resulting in obvious phase separation and poor mixing of the compounded materials, and the material could not be pelletized, as shown in Figure 2C.

To address the significant differences in SME between laboratory and pilot scales and to improve the process, we made modifications to the screw design (increasing melting and mixing), the temperature profile (cooler), and the screw speed (reduced). Figures 3A, 3B, and 3C show that after implementing these improvements, the pressure response, mixing, and process stability were all enhanced.

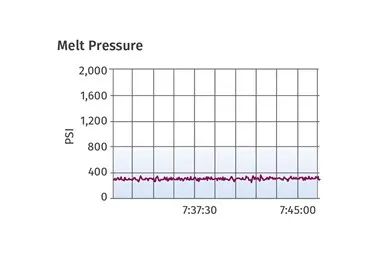

Figure 3A shows a stable pressure response with negligible fluctuations over time. Similarly, Figure 3B shows an improved homogeneous melt with no signs of phase separation or poor mixing. Figure 3C indicates that process improvements allow the masterbatch to be pelletized. The improved process has an SME of 0.079 kWh/kg (approximately 5% lower than the SME of the 26 mm TSE). Additionally, the expected rate estimated according to Formula 2 has been achieved, which is 3.64 times higher than the rate of the 26 mm TSE.

Figure 3A shows the pressure variation over time during the 40 mm TSE compounding process after adopting a new screw design and reducing processing temperature and screw speed. Figure 3B shows the uniform melt at the extruder discharge port.

Commercial-scale compounding using a 92 mm TSE

Similar to the scale-up transition from laboratory scale to pilot scale, optimized process conditions—namely the screw design, temperature profile, and screw speed of the 40 mm TSE—were employed during the scale-up from a 40 mm TSE to a 92 mm TSE. The corresponding scale-up factor for the 92 mm TSE was estimated using Equation 2. Surprisingly, the implementation of these conditions did not translate into a reliable and sustainable process on the commercial-scale extruder.

For example, Figure 4 shows a photo of a scrap bin located below the directional valve downstream of the 92 mm TSE. The photo shows some solid polymer particles being discharged from the extruder. The unevenness of the melt clearly indicates that when the optimized conditions used for the 40 mm TSE are applied to the 92 mm extruder, insufficient energy is transferred to the material. This is consistent with an SME input of 0.026 kWh/kg, which is 69% and 67% lower than the inputs for the 26 mm and 40 mm TSE, respectively.

Figure 4 Solid polymer particles discharged through the diverter valve of the 92 mm TSE are collected in a waste bin.

Root cause analysis indicates that the low shear stress transmitted to the material is likely due to a lubricating effect caused by low viscosity of the raw material on the extruder barrel and screw. This phenomenon did not occur on the 26 mm TSE, and although there were slight signs of it on the 40 mm TSE (such as phase separation and poor mixing), the issue was successfully resolved at this scale through appropriate adjustments as described above.

It is noteworthy that as the size of the extruder increases, the area/volume (A/V) ratio of the heat exchanger (TSE) decreases sharply. This means that as the diameter increases, control over variables such as heat transfer becomes increasingly poor. The result of the analysis was a reassessment of screw design and feed configuration. After implementing these improvements, the SME increased from 0.026kWh/kg to 0.086kWh/kg.

Figures 5A and 5B show photographs of the discharged melt and pelletized masterbatch after implementing these improvements. Figure 5A displays a completely homogeneous melt, with neither phase separation nor unmelted pellets, while Figure 5B demonstrates that the process can produce pelletized masterbatch. Ultimately, this process is capable of achieving the corresponding economically feasible scale-up ratio (estimated using Equation 2), which is 12.17 times higher than that of the 40 mm TSE.

Figure 5A shows the fully homogeneous melt discharged through the 92 mm TSE die; Figure 5B shows the masterbatch pellets.

Conclusion

The scaling-up of the TSE process from laboratory scale to commercial scale involves multiple aspects.Although formulas may provide potential achievable rate indicators, other factors may hinder the scaling-up process. Therefore, an appropriate scale-up strategy should be determined/defined based on the analysis of as much process data as possible at each scale (unit operations and their sequence, boundary conditions, physical and chemical properties of raw materials, process limitations, etc.).

In this case study, the specific mechanical energy (SME) obtained from the laboratory-scale TSE is a key parameter and reference for subsequent scale-up production. Furthermore, the laboratory-scale compounding process did not exhibit any type of limitation (such as heat transfer, feeding, raw material fluidization, etc.); therefore, the power/volume method (Equation 2) was chosen for scale-up to larger extruders (40 mm and 92 mm TSE).

Despite encountering poor process instability and quality issues in the 40mm and 92mm scale pilot-scale upscaling,However, as long as subsequent process changes and adjustments at this scale match the SME obtained on the 26mm TSE, the process can achieve the desired masterbatch quality stability and reliability.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track