Unveiling! How Does This Injection Molding Machine Achieve Drying-Free Injection?

In the traditional injection molding production process, drying of plastic pellets has always been an indispensable step. Common engineering plastics such as ABS, PET, and PC often require drying before use, which not only consumes time and energy but also easily leads to material performance degradation. Zhoushan Hongtuo Machinery Co., Ltd. has developed an internal circulation dehumidification series injection molding machine, offering a more efficient and environmentally friendly solution to help customers simplify processes and reduce costs.

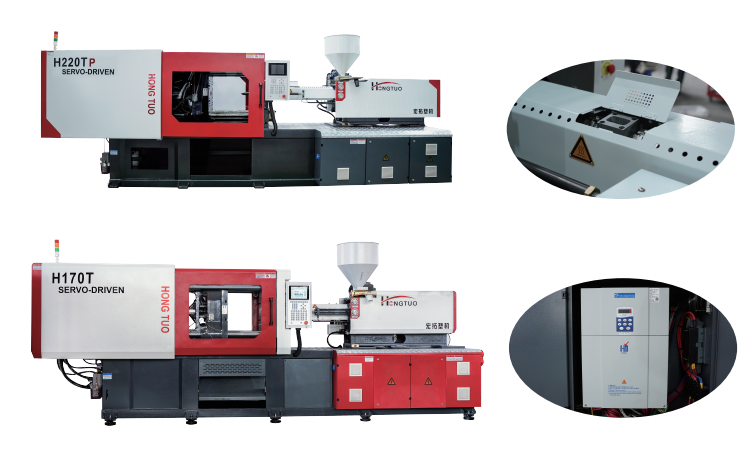

(Internal Circulation Dehumidifying Series Injection Molding Machine)

Product Advantages

✔ No need for drying, cost-saving

Traditional injection molding requires pre-drying of raw materials, while Hongtuo's internal circulation dehumidifying injection molding machine can mold directly, eliminating the need for drying equipment and electricity costs, reducing production steps, and lowering operating costs.

✔ Maintain the properties of raw materials and ensure stable product quality

Without the need for high-temperature drying, the plasticity and color of the raw materials are better preserved, avoiding property changes caused by excessive heating. The quality of the finished product is closer to the original state of the raw materials.

✔ Reduce dust, improve the production environment

The drying process tends to generate dust, affecting workers' health and equipment cleanliness. The Hongtuo internal circulation dehumidifying injection molding machine eliminates the drying step, reducing dust pollution, and making the production environment cleaner and safer.

✔ Easy to operate and highly efficient in production

The equipment adopts a standardized operating mode, compatible with ordinary injection molding machines without requiring complex adjustments, while optimizing the production process and improving overall efficiency.

Technical Principles

Based on traditional injection molding machine technology and processes, Hongtuo has developed a new generation of internal circulation dehumidifying injection molding machines. Using independently developed screws, it does not require auxiliary drying equipment. Through the internal circulation dehumidification system, moisture, volatile additives, and low molecular gas raw materials in the melt are directly expelled during processing, thereby achieving a drying-free effect.

For special engineering plastics that tend to generate small molecular volatiles during processing and require extremely low moisture content, an internal circulation dehumidification injection molding machine can effectively remove the gases produced during processing. This solution addresses the issue of product performance indices failing due to poor dehumidification and also avoids the high energy consumption problem associated with prolonged drying.

Application areas

In the injection molding industry, where all raw materials need to be dried to remove moisture before processing and production, the focus is on the processing fields of ABS, PET, PC, PA, POM, PMMA, engineering plastics, and moisture-sensitive biodegradable plastics.

Biodegradable plastic: Eliminate the necessary drying process, directly produce high-quality products, and make adjustments simpler.

2. Transparent plastics: Easily resolve common appearance defects in thick-walled products, ensuring product transparency.

3. Engineering plastics and high-temperature dehumidifying drying plastics: effectively remove small molecular volatiles and avoid the high energy consumption problem of high-temperature drying.

4. Recycled Plastic: Break through the limitations of traditional drying, significantly enhancing the gloss and performance of recycled material products.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track