Uniloy Expands Product Line with 35-Ton Extrusion-Blow and 105-Ton Injection-Blow All-Electric Equipment at K 2025

Preface:Uniloy has launched two new energy-efficient blow molding machines, both equipped with remote monitoring and troubleshooting capabilities.

Blow molding machine -

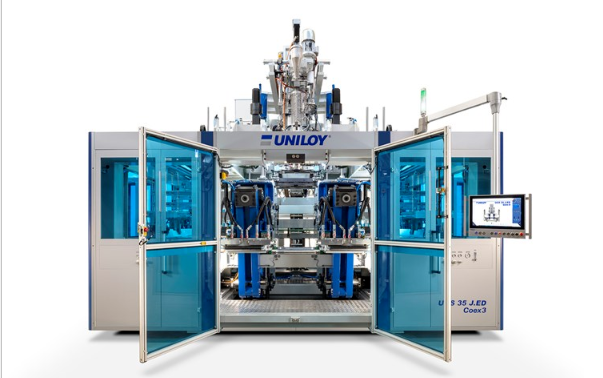

At the K 2025 exhibition held in Düsseldorf, Germany, Uniloy showcased two brand new all-electric machines. One of them is the UCS 35 J.ED Coex3 reciprocating continuous blow molding machine, which features a clamping force of 35 tons, a mold opening stroke of 700 mm, and is equipped with an easily adjustable rear cooling station. This model enhances Uniloy's UCS electric series product line, with the maximum clamping force of series machines reaching up to 40 tons. The displayed machine is configured with three independent extruders and utilizes an optimized screw design, allowing for 100% recycled material filling in the middle layer of three-layer containers.

Uniloy has completed its UCS electric series product line with this 35-ton equipment. This reciprocating three-layer co-extrusion equipment can achieve 100% recycled material filling in the middle layer of the container. (Image source: Uniloy)

This device features a wide safety door and a certified low-speed operation mode, ensuring safe and convenient mold changes, equipment debugging, and maintenance operations. Additionally, it is equipped with a Uni-Smart control interface and an OPC-UA interface for Industry 4.0 integration, supporting remote control via wired or Wi-Fi connections for production monitoring and predictive maintenance.

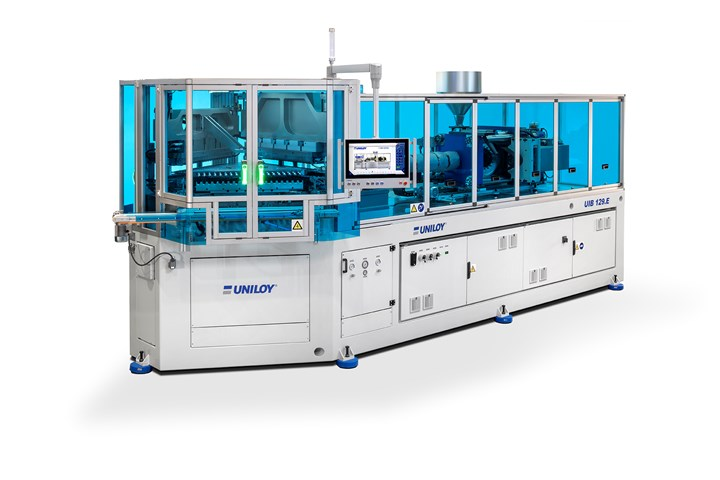

Uniloy has enriched its first fully electric injection-blow series product line with this 105-ton equipment.

The second new model is the UIB 129.E all-electric injection blow molding machine, with injection and blow molding clamping forces of 105 tons and 18 tons, respectively. This model complements Uniloy's first all-electric injection blow molding machine series, which was launched around NPE 2024, with the first model being an 85-ton device. According to Uniloy, the energy consumption of this equipment is only 18 kilowatts, achieving a 60% energy saving compared to the hydraulic version. The equipment is also equipped with the OPC-UA communication protocol, enabling real-time production monitoring and remote connectivity for predictive maintenance.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

List Released! Mexico Announces 50% Tariff On 1,371 China Product Categories

-

Dow, Wanhua, Huntsman Intensively Raise Prices! Who Controls the Global MDI Prices?

-

Clariant Unveils Cost-Cutting Plan Details, Plans to Shut Down Multiple Plants

-

New Breakthrough in Domestic Adiponitrile! Observing the Rise of China's Nylon Industry Chain from Tianchen Qixiang's Production

-

Nissan Cuts Production of New Leaf EV in Half Due to Battery Shortage