Types and features of plastic drying equipment: How to Choose the Right Model? Read This Article!

Proper drying of polymer resins is crucial during molding or extrusion processing of these materials to avoid operational errors and defects in the finished products.

Resin dryers provide convenient, quick, and efficient drying treatment for injection molding and extrusion processing.Its types are diverse and can provide high-quality drying effects for almost all application scenarios. Some of the most common types include:

Hot air dryer:No desiccant

Compressed air dryer: Non-membrane or low dew point membrane

Desiccant Bed/Dehumidification Type:Single or multiple bed types

Desiccant Wheel/Dehumidification Type:Spin the wheel

Vacuum dryer:Using heat and vacuum to remove moisture from materials.

Dryers are suitable for handling molding machines and extruders with capacities ranging from as low as 1 pound per hour to over 6,000 pounds per hour.

Optional solutions range from small, energy-efficient portable devices to large centralized systems. Many drying solutions feature compact designs and integrated conveying systems to ensure that dried materials are directly delivered to processing machines.

Dryer type

01 Hot air dryer:

Most economicalThe resin dryer usesUsing a one-way process, draw the atmosphere into the filter and heater, push the heated air through the drying hopper, and discharge it back into the atmosphere.。

Ambient air is heated and introduced into a drying hopper. Surface moisture is removed from non-hygroscopic materials, which are typically dried at temperatures of 180º F (82.22º C) or lower. For hygroscopic materials, the air heats the pellets, bringing internal moisture to the surface for drying. The maximum hot air temperature is determined by the material's softening (not melting) temperature. Such dryers are generally not used for hygroscopic materials, except when small quantities are taken from sealed resin bags.

02Compressed Air/Dehumidification/Membrane Dryer:

Mainly used forLow throughputApplications andSmall machineThe application requires a large amount of compressed air. High-pressure compressed air expands to produce a larger volume of low-pressure air. The expanded air passes through a heater and then enters the drying hopper. The heated moist air is discharged from the drying hopper into the atmosphere.

The non-membrane version provides factory (for process use) air with a dew point of 40ºF to 50ºF (approximately 4.44ºC to 10ºC). Factory compressed air typically provides air with a dew point of approximately 0 to +15ºF (approximately -17.8ºC to -9.44ºC). If the central compressed air system is equipped with a central compressed air dryer, this may reduce the compressed air dew point low enough (0 to -15ºF (approximately -17.8ºC to -26ºC)) to achieve proper drying without the need for an additional membrane on the dryer.

Membrane versions allow compressed air to pass through a membrane to remove moisture from the air. Compressed air dryers using membranes can produce air at -40°F (-40º C) or better.

Some applications may require the installation of a HEPA filter at the air outlet of the drying hopper to capture any discharged dust particles and prevent them from entering the atmosphere.

03Desiccant bed/dehumidifying dryer:

This type of dryer usesDesiccant materialsWhen beads (for example) absorb moisture, they undergo a regeneration process to remove the moisture once they are saturated, allowing the desiccant to be regenerated and moisture to be absorbed into the beads again (adsorption process). Extremely hot air (400 to 800°F, approximately 204 to 427ºC) passes through the desiccant, releasing the moisture absorbed from the airflow. However, the beads must be cooled before returning to the drying process to avoid melting the resin due to a sudden temperature rise when handling on the bed.

The multi-bed desiccant technology can use one or two blowers. The blowers provide process air, cooling air, and regeneration air, guiding the air through the desiccant beds using switching valves.

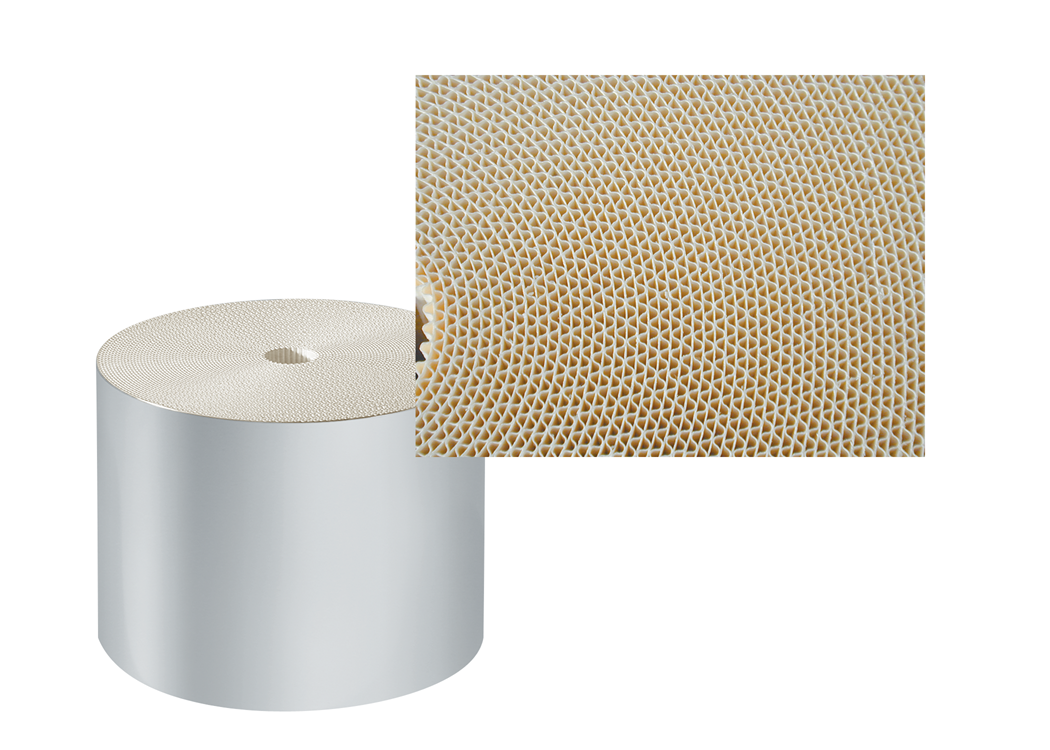

04Desiccant rotor (honeycomb type) dryer:

The desiccant wheel dryer provides a different type of desiccant drying method. They...More efficient and more compact.And compared to other models, it requires less. Traditional desiccant dryers use a large amount of molecular sieves (in granular form) consisting of at least 30% clay. These desiccant beads degrade over time. The design of the desiccant wheel is completely different. It is composed of pure molecular sieves impregnated on a durable carrier medium. This material is formed into a reinforced honeycomb structure.

Desiccant wheel dryers can provide stable and extremely reliable dew points under almost any environmental conditions. A stable process temperature means no bed temperature peaks; these dryers take only a few minutes to start drying from a cold start; due to the low rotor pressure drop, they can achieve above-average process airflow with minimal energy; the large surface area to volume ratio of the desiccant provides faster adsorption and desorption (regeneration) regulation; the honeycomb structure has a thin layer of desiccant that absorbs moisture evenly; during regeneration, the absorbed moisture easily evaporates off the media, allowing the dryer to achieve efficient continuous drying as the wheel rotates slowly.

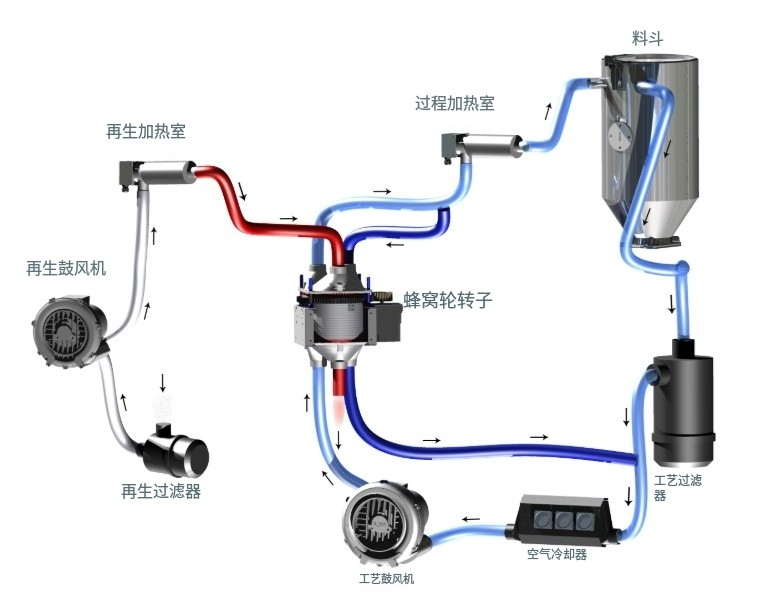

The working principle of a wheel dryer

The rotary dryer operates simultaneously through three processes:Drying, regeneration, and cooling.

In the drying circuit, moist air from the drying hopper passes through a filter, cooler, and blower to reach the desiccant wheel, where moisture is extracted from the process air, and then it returns to the drying hopper.

The regeneration process uses separate filters, blowers, and heating chambers to remove moisture from the desiccant wheel, expelling the hot, moist air outside the dryer.

The regeneration process uses separate filters, blowers, and heating chambers to remove moisture from the desiccant wheel, discharging hot, humid air outside the dryer.

After regeneration comes cooling, with a portion of the low dew point cooling air being directed towards the desiccant wheel (before the heater) to enhance its moisture absorption capacity in preparation for the next drying cycle.

05Vacuum dryer:

Vacuum dryerLowered the boiling point of water.In a vacuum degree of 90%, water boils at 122ºF (approximately 50ºC). The current design employs an insulated vacuum container; an insulated stainless steel hopper with drying temperatures up to 662ºF (approximately 350ºC); weighing sensors to control material levels and display material consumption; a dry air membrane for purging the vacuum container; and an insulated retention hopper for drying materials. The pellets are heated to the required temperature. When vacuum is applied, the water vapor inside the resin boils. Compared to traditional drying methods, the resin is ready for processing in a shorter time. The vacuum dryer has fewer moving parts, making it suitable for certain processing applications.

Control system

The control system monitors and maintains optimal performance during the drying process. Today's control platforms offer many control and diagnostic functions, including airflow and temperature control. Some platforms are capable of adjusting dew point parameters and incorporating dryer maintenance programs into routine operations and usage.

Dryer control systems are typically equipped with color, user-friendly touch screens that intuitively display drying parameters and processes. The intuitive layout enables operators to quickly learn and initiate dryer functions.

The dryer control device meets the data collection requirements of Industry 4.0 used in the plastics industry. The advanced control device optimizes moisture removal through features such as energy control algorithms and integrated conveying control with purge take-off functionality.

The remote monitoring feature allows operators to closely monitor operations via mobile phones, tablets, or computers.

The process data collected by modern dryer controllers enables smarter facilities and displays trend graphs of key parameters.

Dry hopper

All types of drying applications require drying hoppers. Drying hoppers allow the appropriate amount of material to reside for the right amount of time. This enables the dryer to remove the necessary moisture from the resin.

The design of the resin drying hopper is another key consideration in the plastic drying system.Flow design, size determination, and thermal insulationThe key factors to understand when choosing an ideal drying hopper.

Flow design (mass flow or funnel flow) will affect the material passing through the hopper.

In overall flow design, all materials flow through the hopper at the same rate, and the material flow direction is opposite to the direction of the drying air (countercurrent). In a funnel flow system, materials flow faster in the center of the hopper and slower near the sides and walls of the hopper. Overall flow design is necessary to ensure that the material has adequate residence time before entering the feed throat of the processing equipment.

The size of the drying hopper can be determined by weight or volume. The average capacity of small drying hoppers ranges from 0.1 cubic feet to 30.0 cubic feet. These are usually mounted on floor stands or portable carts, typically located next to or near the processing machine. For some low throughput applications, drying hoppers can be directly mounted on the feed throat of the machine. The average capacity of large drying hoppers is from 30 to 425 cubic feet, and they are usually installed on floor stands or mezzanine platforms due to the larger footprint requirements of the equipment.

To determine the size of the drying hopper by weight, its capacity must equal the machine's processing rate (pounds/hour) multiplied by the material residence time (hours). For example, if your machine can process 100 pounds of material per hour and the material residence time is 4 hours, you will need a drying hopper with a capacity of 400 pounds.

The formula for determining the size of a drying hopper by volume is: machine processing rate (lbs/hour) multiplied by material residence time (hours), then divided by bulk density (lbs/cubic foot). For example, 100 pounds of material requiring a 4-hour residence time with a density of 40 lbs/cubic foot would need a drying hopper with a capacity of 10 cubic feet.

Many engineering resins can refer to a bulk density of 35 to 40 lbs/ft³ for virgin pellets (refer to material supplier data sheets). Filled resins—such as ABS with 40% glass filler—are heavier, while regrind is often less dense. The particle size and shape of regrind can also affect material density. For example:

PET virgin pellets:52 to 53 pounds per cubic foot

PET recycled sheet material:The density is usually 17 to 23 pounds per cubic foot, depending on the thickness of the board.

PET bottle preform recycled material:Average 26 to 38 lbs/ft³

PET bottle flakes:Typically 18 to 23 lbs/ft³

PE virgin pellets:32 to 35 lbs/ft³

PE film:7 to 11 pounds per cubic foot (depending on specifications)

Due to various reasons, non-insulated drying hoppers are not very popular: they waste energy, overheat the process area, affect operator safety, and the material adjacent to the hopper wall will be at a temperature below the selected set point.

Resin moisture measurement equipment

Understanding the initial moisture content of plastic resins is crucial for determining their drying time. The drying time and temperature guidelines provided by material suppliers are often based on assumed initial moisture content, which can lead to over-drying or under-drying of the resin, resulting in process and part issues.

Resin moisture measurement devices come in two forms: offline (laboratory) or online. Laboratory equipment can also provide complete chemical analysis, while online equipment is usually cheaper and easier to use.

Offline devices include:

Weightlessness Analyzer:Measure the total change in weight of the resin sample when heated at a specific temperature.

Moisture AnalyzerDetect the moisture content using a chemical process.

Online moisture analyzer includes:

Capacitive sensor:Measure the capacitance change caused by dielectric variation.

Microwave:The working principle is that the dielectric constant of water is significantly higher than that of most other materials. Due to the dipole effect of water molecules, the resonance frequency of a microwave resonator changes with variations in water content. These changes are detected by the sensor electronics and scaled through a calibration process to provide an accurate reading of the presence of moisture.

Near-infrared:Using a beam to excite water molecules and measuring the wavelength of light absorption to indicate the moisture content in resin.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track