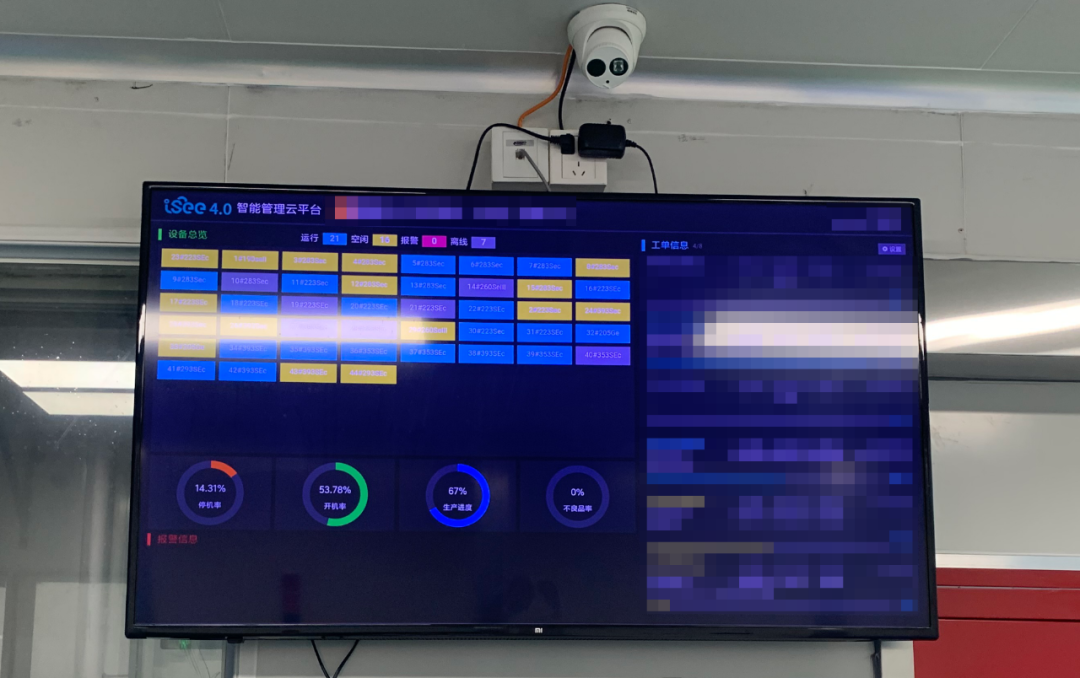

"transparent manufacturing process: How the iSee 4.0 Intelligent Management Cloud Platform Makes Injection Molding Workshops 'Open Kitchen and Bright Stove'"

From Xibei's pre-made dishes to injection molding workshops, transparency is becoming a mandatory question in the manufacturing industry.

Recently, the remote "battle" between Luo Yonghao and Xibei has pushed pre-prepared dishes into the spotlight of public opinion. Consumers are eager to know: How is the food they consume produced? The same question exists in the manufacturing industry—customers want to know: In what environment and how are the purchased components produced?

As the "transparent kitchen" solution in the injection molding industry,iSee 4.0 Intelligent Management Cloud Platform SystemUsing digital means to answer this question.

The "pre-made dishes dilemma" in the injection molding workshop:

Trust requires seeing to believe.

Consumers are curious about the kitchen behind pre-made meals, just as manufacturing enterprise clients are particularly interested in the production processes of their suppliers.

1 Do the raw materials meet the standards?

2Are the process parameters strictly followed?

3Is quality inspection reliable?

4How to ensure production efficiency?

iSee4.0 Intelligent Management Cloud Platform SystemA complete transparency solution is provided for the injection molding workshop, making every process visible and clear.

iSee 4.0: Four Major Transparency Scenarios in the Injection Molding Workshop

Real-time monitoring of the operating status of each injection molding machine.

Real-time display of start-up rate, utilization rate, and OEE data.

Automatic equipment failure alarm and dispatch of maintenance personnel.

Mold usage automatic counting, preventive maintenance reminder.

It's like a restaurant displaying kitchen monitoring, allowing customers to understand the production situation at any time.

Complete process record of injection molding process parameters:

Real-time monitoring of key parameters such as barrel temperature, injection pressure, and holding time.

Automatically compare the standard process range, immediately alert when deviations are detected.

Parameter modification access is managed by levels to prevent arbitrary changes.

Ensure that each product is produced under optimal process conditions to address the industry challenge of "inconsistent taste."

Establish a full lifecycle quality traceability system.

From raw material storage to finished product delivery, each batch of products has a digital identity card.

Real-time upload of quality inspection data, automatic generation of SPC statistical analysis.

Record of the entire process of handling defective products, tracing the root cause

Allow customers to clearly understand product quality information, just like checking the ingredient list of pre-made dishes.

Real-time visualization of order execution status:

Order completion progress is updated in real-time, and delivery date forecasting is accurate and reliable.

The capacity load is clear at a glance, enabling scientific production planning.

Material inventory dynamic monitoring, automatic triggering of purchasing alerts.

Help customers accurately grasp order status and build delivery trust.

From Prepared Dishes to Injection Molded Parts: Transparency is the Common Future of Manufacturing

The debate between Lao Luo and Xibei reveals the fundamental change in the consumer market: consumers not only want to eat well but also want to understand what they are eating. Similarly, manufacturing clients not only want good products but also want clarity in the production process.

iSee4.0 Intelligent Management Cloud Platform SystemIt is the "Bright Kitchen and Stove" project of the injection molding industry, which uses digital means:

1Enable devices to "speak" and report their operating status in real time.

2Make the process "memorable" by fully recording the production process.

3Make quality "traceable" and quickly locate the root cause of problems.

4Make management "transparent" and comprehensively improve operational efficiency.

In conclusion: Transparency is the core competitiveness of the new manufacturing era.

In this era where everything can be digitized, invisible production processes will become a thing of the past, and transparent manufacturing is defining new industry standards.

The transparency revolution in the injection molding workshop has begun. Is your company ready?

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track