Toshiba Global Open Day: Humanoid Robot Debuts at Center Stage, Ushering in a New Decade of Intelligent Manufacturing

On September 12th, the "AI Without Boundaries, Intelligent Manufacturing Coexistence – Tuosida Global Open Day 2025" successfully concluded in Dongguan. After several years, it was once again opened to global customers and partners, comprehensively showcasing Tuosida's cutting-edge technological breakthroughs and industrial integration practices in the fields of industrial AI and intelligent manufacturing through dual-base live demonstrations, new product launches, roundtable dialogues, and ecosystem signing ceremonies.

This event brought together over a thousand industry elites, including representatives of domestic and overseas clients, leading domestic AI model enterprises, global technology manufacturing giants, leaders in the intelligent device appearance and structure field, and representatives from several comprehensive national technology innovation centers prioritized by the country. It established a high-end exchange platform characterized by "openness, collaboration, and symbiosis," providing a more comprehensive display of Topstar's full-stack closed-loop capabilities from core components and high-end equipment to smart factory solutions. This injects strong momentum into promoting the construction of a new "intelligent manufacturing symbiosis" industry ecosystem.

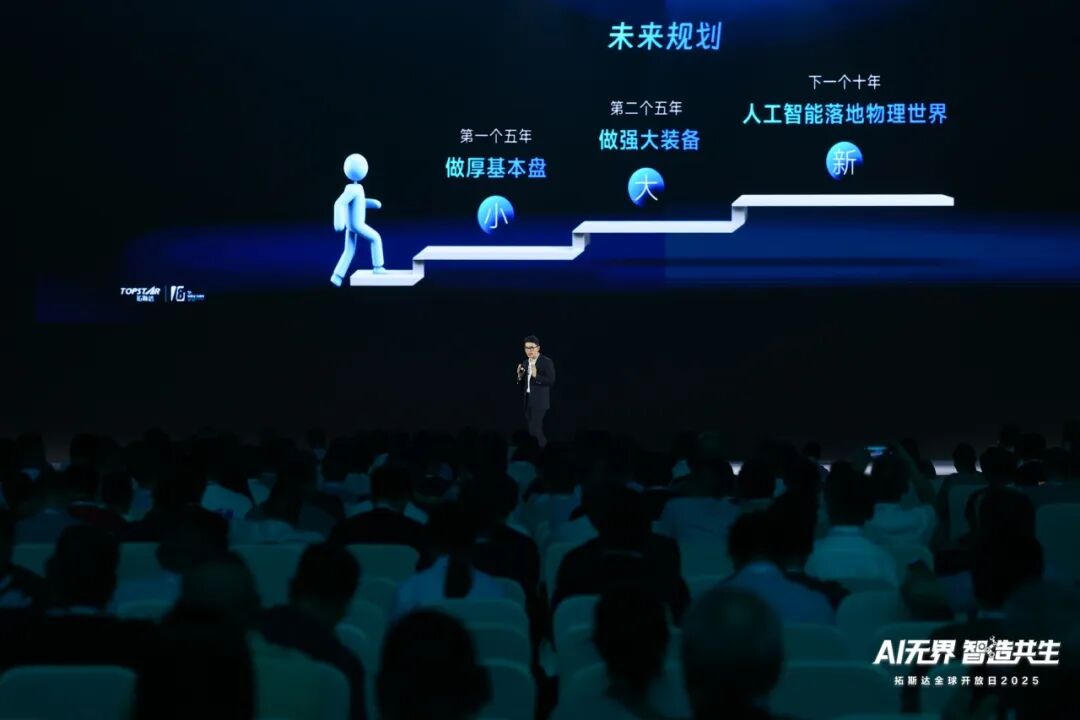

Focusing on "Small, Large, and New," deepening global presence

Part.1

Chairman Wu Fengli of Topstar shared the core logic and evolution path of the company's business growth over the past eighteen years, centered around the two fundamental materials of plastics and metals.Through a clear strategic blueprintHe explained how Topstar, with the value of "wholeheartedly serving customers," continuously focuses on solving process issues, standardizing product portfolios, developing core components, and optimizing organizational processes.Build replicable solutions and drive the company's steady development based on strong organizational capabilities.。

At the same time, Chairman Wu Fengli elaborated on the company's future development direction on-site: to continuously consolidate and expand its main business, focus on high-end intelligent equipment, and promote the application of artificial intelligence technology in manufacturing scenarios. In the future,Tusda's humanoid robots will achieve precise solutions to practical application challenges through deep integration of craftsmanship and scenarios, ultimately building a sustainable business closed loop.。

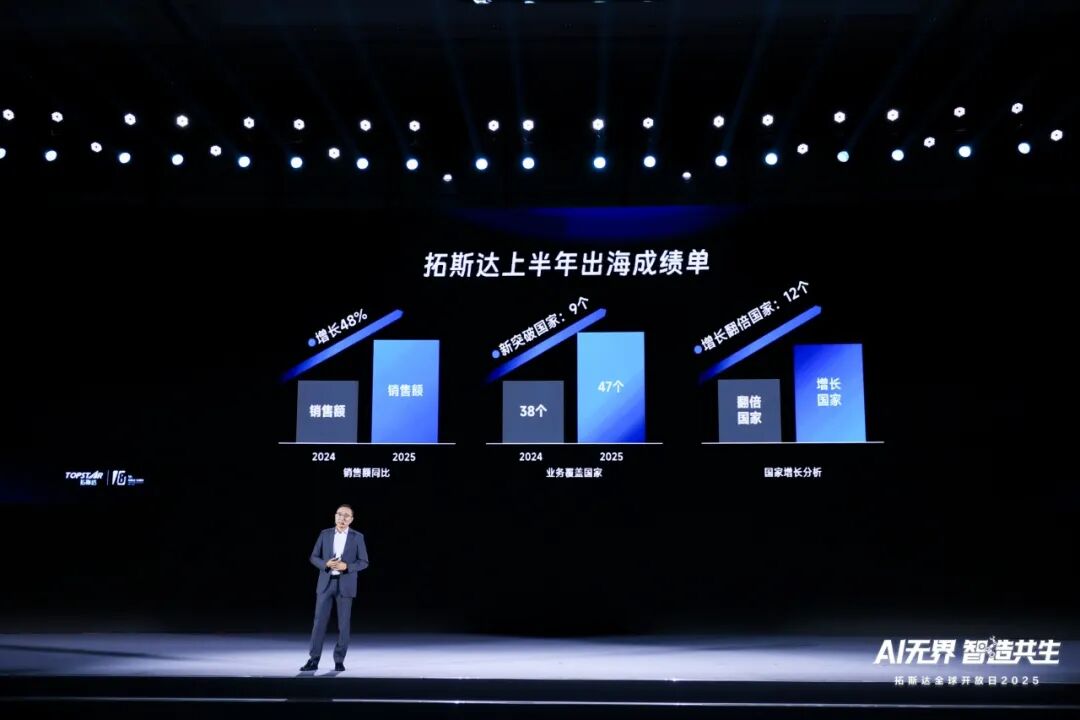

In terms of overseas expansion, Tosun Vice President Jiang Xiangqian shared cases of providing attentive services and ensuring rapid delivery, which have enabled the company to establish a solid customer base and supply chain network worldwide. To date, Tosun's business has covered more than 50 countries and regions globally.

Humanoid robot debut, building a full-stack closed-loop ecosystem

Part.2

From deep cultivation in the domestic market to global expansion, and from technological innovation to product implementation, the company continuously promotes the "boundaryless integration" of AI and the manufacturing industry at the hardware, software, and system levels.

Matrix Intelligence CEO Huang Jing officially launched the world’s first humanoid robot—Xiao Tuo. This also marks…The first humanoid robot applied in the injection molding industry marks a crucial step forward in the application of humanoid robots in industrial scenarios.。

"Xiao Tuo," based on the embodied model jointly developed by Topstar and Zhipu, is capable of autonomous reasoning and decision-making for complex tasks. Leveraging the scenario understanding and technological expertise accumulated from serving 15,000 industrial clients,"Xiao Tuo" has completed multiple rounds of verification in the injection molding workshop.By integrating a 3D camera with an AI vision inspection system, it can identify the yield of injection molded parts in real-time and autonomously complete processes such as tray loading, achieving full-process automation from inspection to operation.

The manufacturing process of humanoid robots itself embodies the technological integration of high-end equipment. The core components are processed using the Evermi DMU400 five-axis CNC machine, leveraging self-developed spindle and GTRT gear-driven cradle turntable technology.Achieved high rigidity cutting with precision exceeding one-third of a hair's breadth, providing robots with reliable "steel bones."。

The most hardcoreTosda has made significant breakthroughs in key technologies such as servo control. The company's chief servo technology expert, Dr. Wang Zhicheng from the Shenyang Institute of Computing Technology, Chinese Academy of Sciences, shared on-site the innovative application of mechanical end jitter suppression control technology, which has been successfully applied to the humanoid robot "Xiao Tuo." This technological breakthrough not only demonstrates the company's strong capabilities in the high-end servo field but also provides critical technical support for the large-scale deployment of humanoid robots.

Most abundantStarting from injection molding auxiliary equipment as its core business in the early stages of development, Topstar gradually expanded into electric machines and has now established a comprehensive injection molding full-chain solution service capability covering everything “from single machines to entire factories.” With nearly 20 years of accumulated experience and a wide variety of application scenarios, it has served more than 15,000 customers.Covering multiple fields such as 3C, medical, automotive, and daily chemicals, it provides a solid verification foundation and ample expansion space for the practical application of Tuosda humanoid robots, effectively supporting the large-scale application of humanoid robots in industrial scenarios.。

The release of "Xiao Tuo" not only showcases the potential applications of humanoid robots in industrial settings but also fully demonstrates...Tosda's integrated closed-loop ecological capability of "technology-manufacturing-product-scenario."。

Partnering with Ecosystem Partners

Promote the large-scale implementation of diverse scenarios

Part.3

In discussing how AI can truly become the "new quality productive force" in the manufacturing industry, Dr. Zhuang Ruiyan, Chief Scientist of the National Technology Innovation Center in the Guangdong-Hong Kong-Macao Greater Bay Area, pointed out in his presentation "The 'Big Future' of Chinese Manufacturing—AI Reshaping Manufacturing and Empowering New Quality Productive Forces" that AI has already become a tangible "new quality productive force" on production lines, driving Chinese manufacturing to leap towards efficiency, quality, and intelligence.

In the face of the rapid development of AI technology, how should the manufacturing industry seize opportunities to achieve breakthroughs? Topstar, together with authoritative institutions and industry leaders such as the National Technology Innovation Center of the Guangdong-Hong Kong-Macao Greater Bay Area and Foxconn Technology Group, engaged in a roundtable discussion on this topic.

In addition, together with several research institutions, universities, and leading industry enterprises, a "Tostars Humanoid Robot Ecological Innovation Alliance" has been jointly initiated to integrate resources from industry, academia, research, and enterprises, accelerating the large-scale implementation and innovative application of humanoid robots in diverse scenarios.

Through cutting-edge, ecological cooperation, and a global perspective, Tuosda is deeply involved in the intelligent transformation process of the global manufacturing industry.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track