Top 10 Emerging Trends in Global Composite Materials (With Market Size Forecast)

01

High-performance resins and adhesives

A major risk with high-performance application materials is the delamination and degradation of composite layers, which occurs when the bonds between layers weaken and compromise structural integrity. Innovations in high-performance resins and adhesives prevent this issue by providing stronger interfacial bonding between the composite layers.

It also adds toughening agents to the material and surface to improve overall toughness and reduce the risk of sudden failure.

Another issue with composite materials is their sensitivity to environmental factors such as moisture, heat, and chemicals, which can degrade their mechanical properties over time. The use of high-performance resins and adhesives enables the materials and surfaces to resist these factors, thereby enhancing the durability and service life of composites.

02

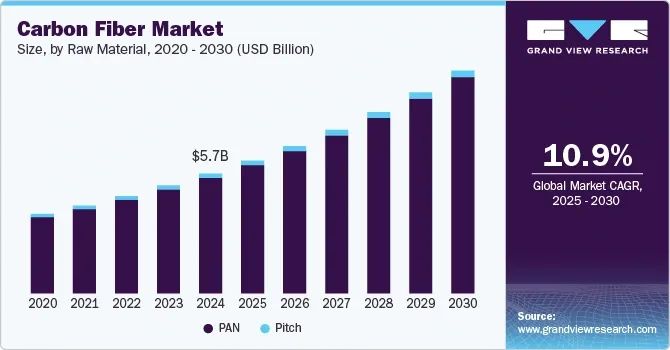

Carbon fiber-based materials

Traditional materials may not achieve the optimal balance of structural performance and may not meet the requirements of high-performance applications. Therefore, carbon fiber-based materials offer an alternative with an excellent strength-to-weight ratio, enabling lighter and more durable structures. They also exhibit superior impact resistance, reducing the risk of hidden damage and thereby enhancing the overall toughness of the composite materials.

In addition, composite materials are usually difficult to achieve thermal conductivity, which limits their application in high-temperature environments.

However, carbon fiber-based materials possess excellent thermal conductivity and can effectively dissipate heat, making them suitable for demanding thermal applications. Therefore, carbon fiber-based materials can be used in industries such as automotive, motorsports, and aerospace.

Aerospace and wind energy are currently the two main sub-markets utilizing carbon fiber-based materials. By 2024, the aerospace industry will account for the largest revenue share at 32.2%.

03

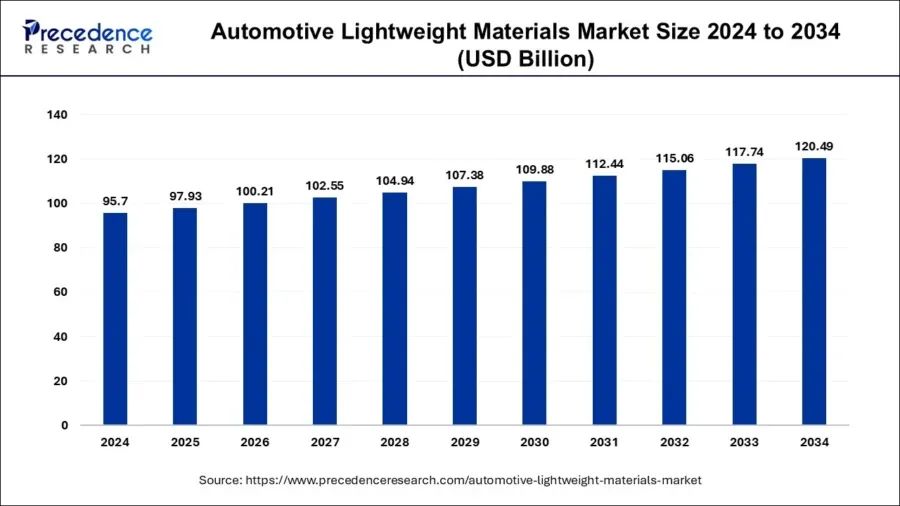

Lightweight

The weight of materials with high mechanical properties limits their application in industries such as automotive and aerospace. To overcome this problem, material manufacturers are developing innovative composite materials, such as carbon fiber reinforced polymers (CFRP) and foam core composites.

04

Advanced Polymer Composites

Achieving effective adhesion between reinforcing fibers and the polymer matrix is crucial for composites, as improper bonding can compromise overall strength and durability. Innovations in polymer composites address this issue by incorporating polymer matrices with enhanced adhesion properties, ensuring a strong interface between the fibers and the matrix.

The enhanced adhesion also translates into improved tensile strength and impact resistance. In addition, startups are incorporating hydrophobic polymers or modified polymer matrices to reduce moisture absorption and prevent material degradation. These advancements help to improve the overall durability and long-term performance of composites, making them more reliable.

05

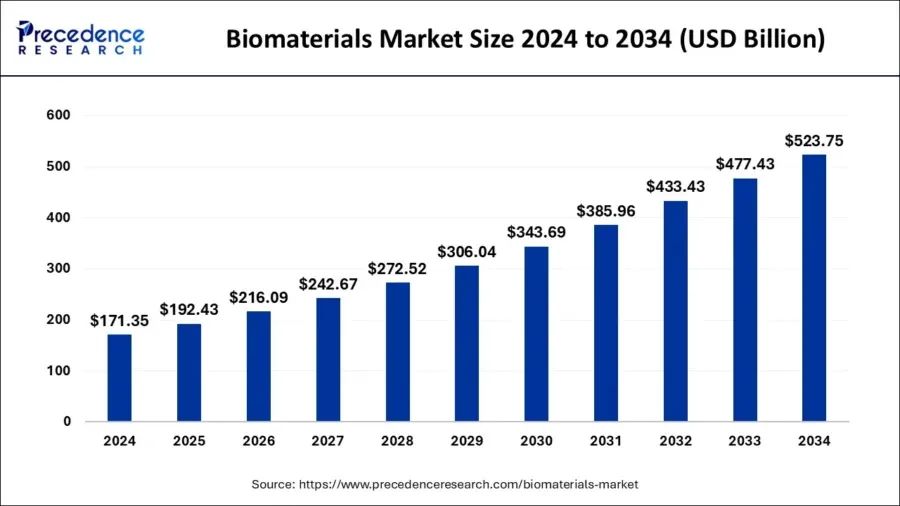

Biomaterials

Emerging companies are developing biocomposite materials that combine high-strength natural fibers or particles with lightweight matrices. These biocomposite materials exhibit an excellent strength-to-weight ratio. They also possess high corrosion resistance, UV radiation resistance, and abrasion resistance.

In addition, flame retardant additives based on biological materials and thermally stable matrices enhance the safety and performance of composites in high-temperature applications.

Compared with traditional composites, bio-based composites offer a wide range of advantages, including sustainability, lightweight strength, and enhanced health and safety benefits.

By 2034, the biomaterials market is expected to reach $523.75 billion, with a compound annual growth rate of 11.82%.

06

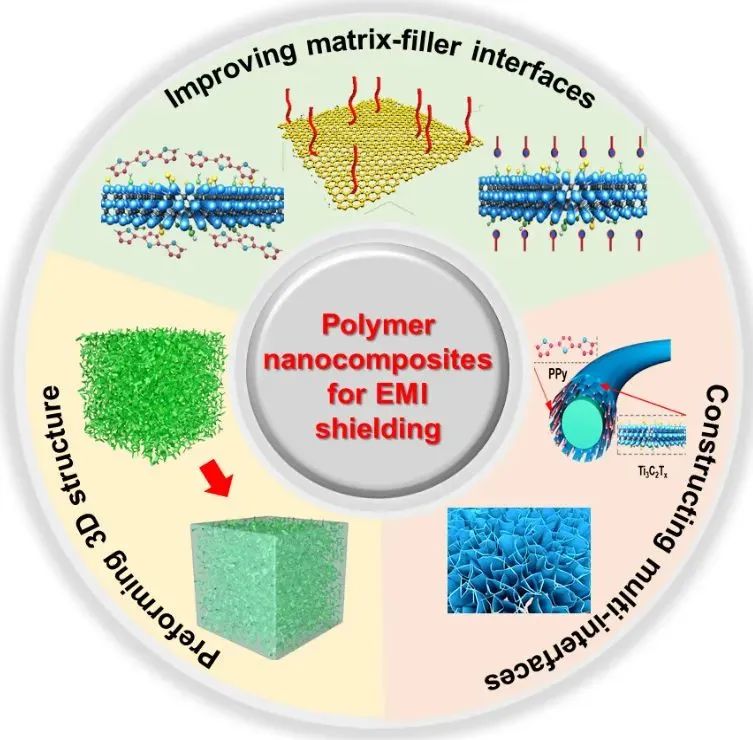

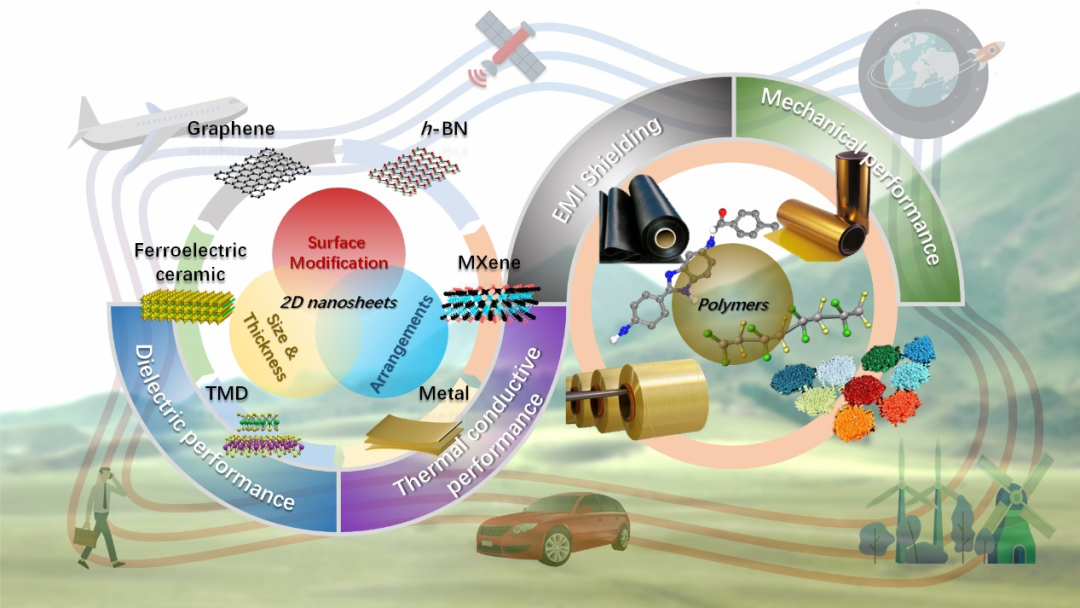

Nanocomposites

The thermal stability and dimensional stability limit the performance of composite materials in high-temperature applications. Nanocomposites overcome this issue by incorporating nanoparticles or nanofillers into the material matrix to enhance overall durability and resistance to thermal degradation. In addition, nanocomposites also improve electrical conductivity, making them suitable for electronic and energy storage applications.

Other innovations in nanocomposites include self-healing capabilities, in which nanoparticles or nanocapsules release healing agents when damage occurs. This leads to the autonomous repair of composite structures. In addition, nanocomposites also exhibit improvements in modulus, flexural strength, heat distortion temperature, and barrier properties.

The packaging industry is a major application area for nanocomposites. Graphene nanoparticles and carbon nanotubes are two types of nanocomposites used in this field.

07

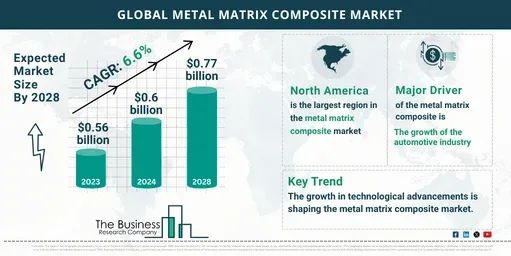

Intelligent Metal Composite Materials

Intelligent metal matrix composites are an innovative class of materials that combine shape memory alloys or shape memory polymers with a metal matrix. These composites respond to external triggers such as temperature or stress by changing their shape or properties. By undergoing reversible deformation, they adjust and adapt as needed.

This unique feature opens up a range of applications in specialized industries. In the aerospace field, smart metal composites can be used for spacecraft components, including self-healing antennas. In the field of smart structures, these composites aid in real-time deformation and behavior adjustment, optimizing aerodynamics and reducing vibrations.

08

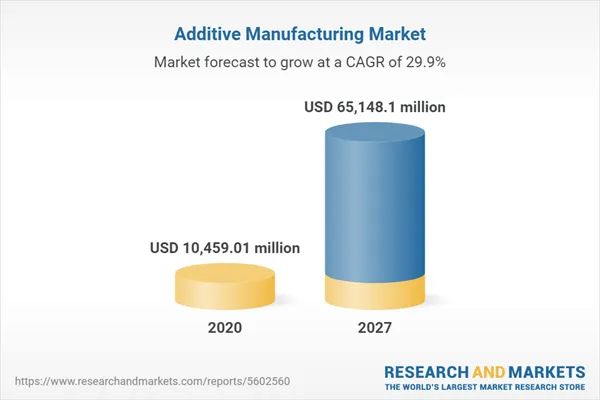

Additive Manufacturing

3D printing overcomes several issues by precisely depositing composite materials layer by layer, allowing for the creation of complex, customized structures. This technology can produce internal features and graded material compositions that are difficult or impossible to achieve through traditional subtractive manufacturing.

Advancements in additive manufacturing technology for composite materials include the use of novel raw materials, such as continuous fibers, nanoparticles, or functional fillers. This enhances the mechanical, thermal, and electrical properties of printed composites.

In addition, the development of multi-material and multi-process printing capabilities has expanded the design possibilities and performance of composite materials.

The additive manufacturing market size is expected to reach $65.148 billion, with a compound annual growth rate of 29.86%.

09

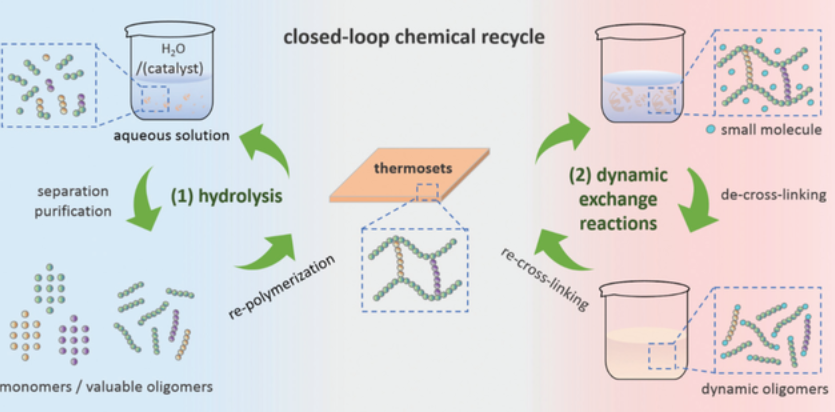

Circular Material Economy

The limited recyclability and end-of-life management of composite materials lead to environmental waste and sustainability issues.

In addition, composite materials typically focus on performance characteristics, making them more difficult to recycle than traditional alternatives. Circular Materials aims to address this issue by incorporating principles of recycling and reusability into material design and production.

Recyclable composite materials with a disassemblable structure can effectively separate and recover their constituent materials at the end of the product’s life cycle.

10

Intelligent Design and Manufacturing

There is a lack of efficient design tools and processes for optimizing composite structures. Therefore, the company is developing intelligent design and manufacturing solutions that utilize advanced computational tools such as finite element analysis (FEA) and machine learning algorithms. This optimizes composite material design and customizes material properties.

These technologies support the development of intelligent design algorithms that take into account factors such as load distribution, stress concentration, and material interactions. Therefore, such tools enhance the performance and durability of composite materials.

Other innovations include generative design techniques, which explore a vast design space to discover optimal composite material configurations and topologies, as well as virtual prototyping and simulation-based testing.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track