The systematic effects of processing aids on pvc melt processing

PVC, as a widely used general-purpose plastic, presents significant challenges in its melt processing due to its unique granular structure and thermal instability. Processing aids, by precisely regulating the melting behavior, rheology, and interfacial properties of PVC, become crucial elements in solving its processing challenges. The following is a detailed analysis from nine dimensions, revealing the key roles of processing aids through the combination of microscopic mechanisms, testing methods, and application scenarios.

1. Promote plasticization: Break hierarchical structures and reduce processing temperatures.

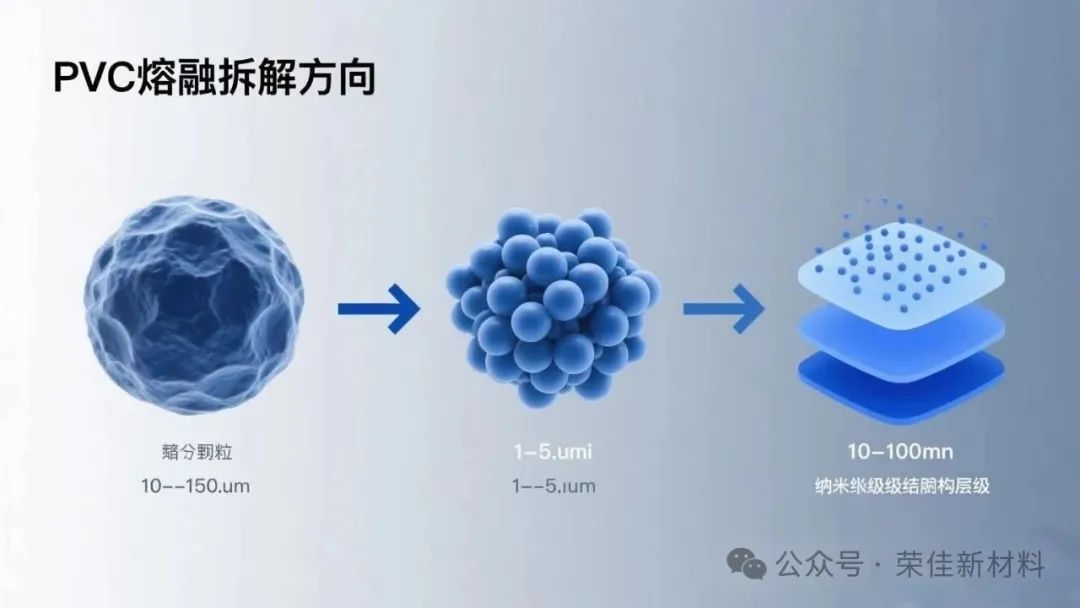

The granular structure of PVC resin exhibits significant hierarchy.Nanometer-sized precipitated particles (10-100nm) coalesce into primary particles (1-5μm), which then aggregate to form the final resin particles (10-150μm).The essence of the melting processIt is the reverse disassembly of this structure, which requires overcoming the cohesion between particles, but high temperatures can lead to thermal degradation of PVC (releasing HCl, causing chain scission).

The core of processing aidsThe function lies in penetrating the gaps between PVC particles through intermolecular forces, weakening the cohesive forces and accelerating structural disintegration. The chemical composition and molecular weight of processing aids are the two main factors affecting the melting of PVC, specifically manifested as:

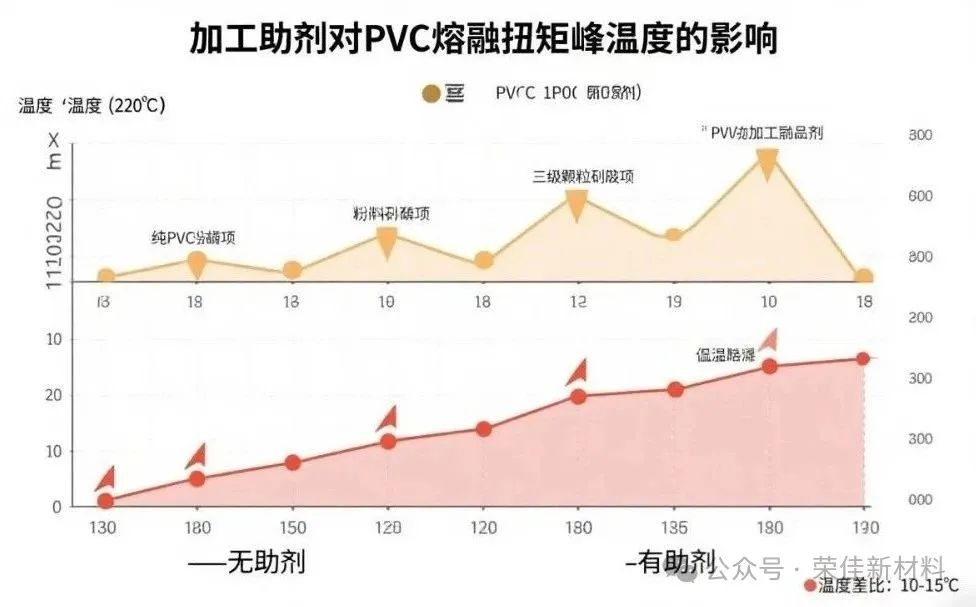

Lower the melting temperatureThe presence of processing aids can reduce processing temperature and accelerate the melting process of PVC. Monitoring with a Haake rheometer or Brabender plastometer reveals that after adding processing aids, the three torque peaks of PVC (powder crushing, secondary particle breaking, primary particle melting) all shift to lower temperatures. The third peak (corresponding to primary particle melting) can be reduced by 10-15°C, avoiding the risk of thermal degradation.

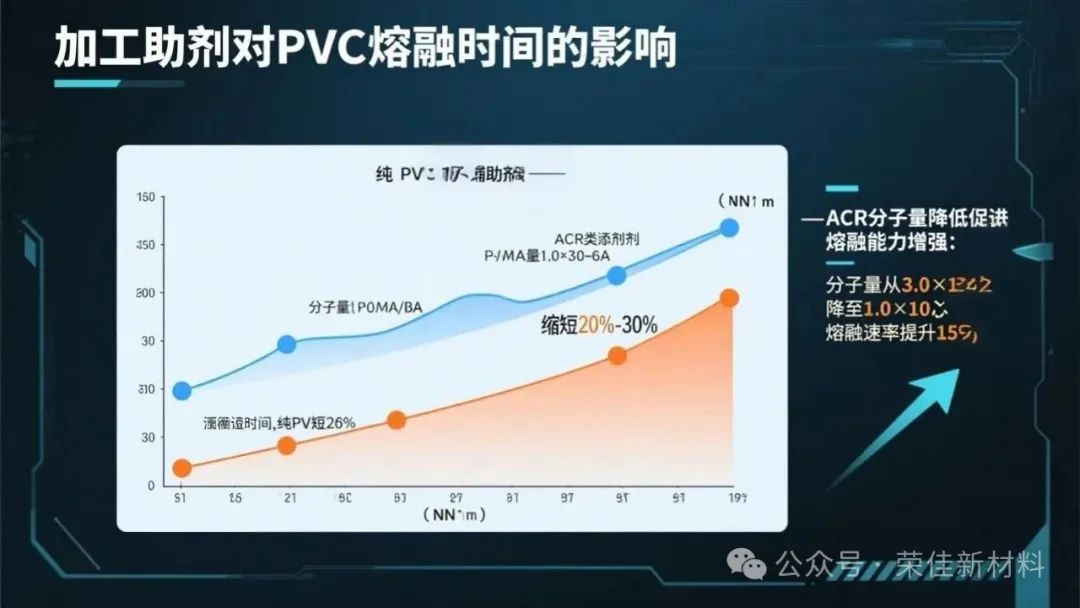

Reduce melting timeAs the amount of processing aid increases, the melting time shortens, and the time to reach equilibrium torque also shortens. The torque-time curve shows that with the increase in processing aid amount (typically 0.5%-3%), the time to reach equilibrium torque is reduced by 20%-30%. For example, when the molecular weight of ACR-type aids (such as P(MMA/BA)) decreases, the melting capability is enhanced — reducing the molecular weight from 3.0×10⁶ to 1.0×10⁶ can increase the melting rate by 15% (see Figure 3).

Ensure uniformity of meltingScanning electron microscopy observations confirm that when processing aids are insufficient, unmelted primary particles remain in PVC products, leading to a decrease in mechanical properties (e.g., impact strength reduced by 10%-20%). Adequate amounts of aids can uniformly disperse the molten phase into 10-100nm nanometer-sized particles, ensuring stable product performance.

2. Improvement of Rheology: Optimize Melt Microstructure to Solve Processing Defects

Poor rheological properties of PVC melt (such as low melt strength and easy breakage) are key factors limiting its forming process.Processing aids improve rheology through a dual mechanism:

1. Microstructural regulationPromote uniform melting of PVC and reduce flow resistance fluctuations caused by incomplete melting of particles.

2. Synergistic effects of molecular chainsThe long molecular chains of processing aids can form a "network structure" in the melt, enhancing intermolecular entanglement and reducing stress concentration during flow.

In actual testing, the improvement in rheological properties can be quantified using equipment such as extruders and twin-roll mixers.

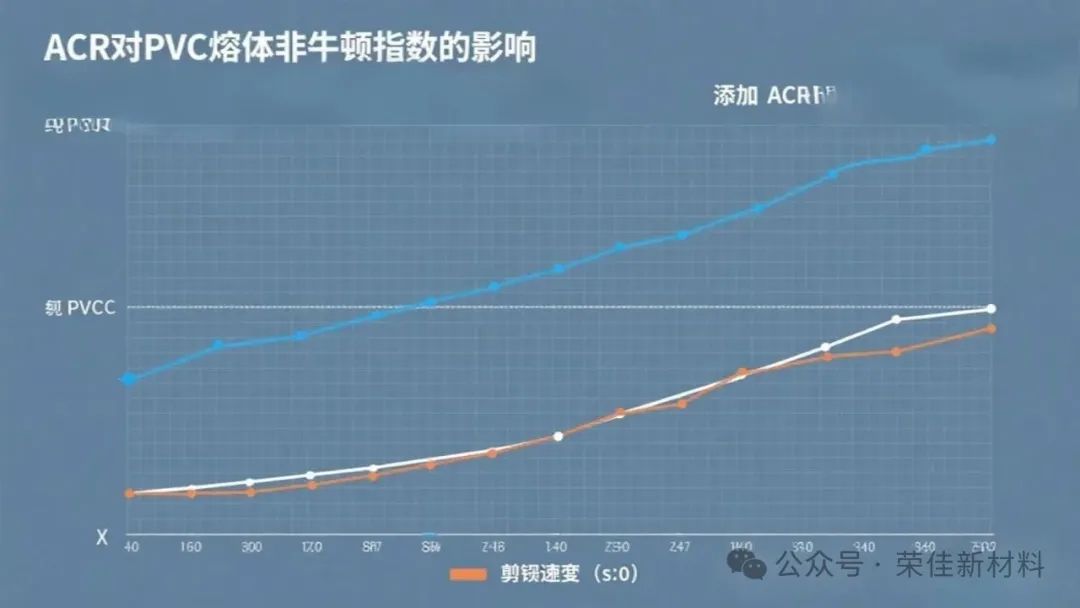

For blow moldingAfter adding 0.8% high molecular weight ACR, the non-Newtonian index of the PVC melt increased from 0.3 to 0.45, broadening the shear rate adaptability and avoiding uneven parison thickness caused by flow rate fluctuations.

- For injection moldingImproving rheological properties can increase the filling rate of the melt in the mold by 10%-15%, reducing defects such as material shortage and sink marks.

3. The Impact on Mold Release ExpansionBalancing forming accuracy and process requirements

Extrusion expansion ratio of polymers The influence of molecular weight, composition, and processing conditions (such as temperature, shear rate, and die exit time) of polymers.Die swell is the volumetric expansion that occurs when a polymer melt exits the mold due to elastic recovery, directly affecting the dimensional accuracy of the product.

The regulatory patterns of processing aids are as follows::

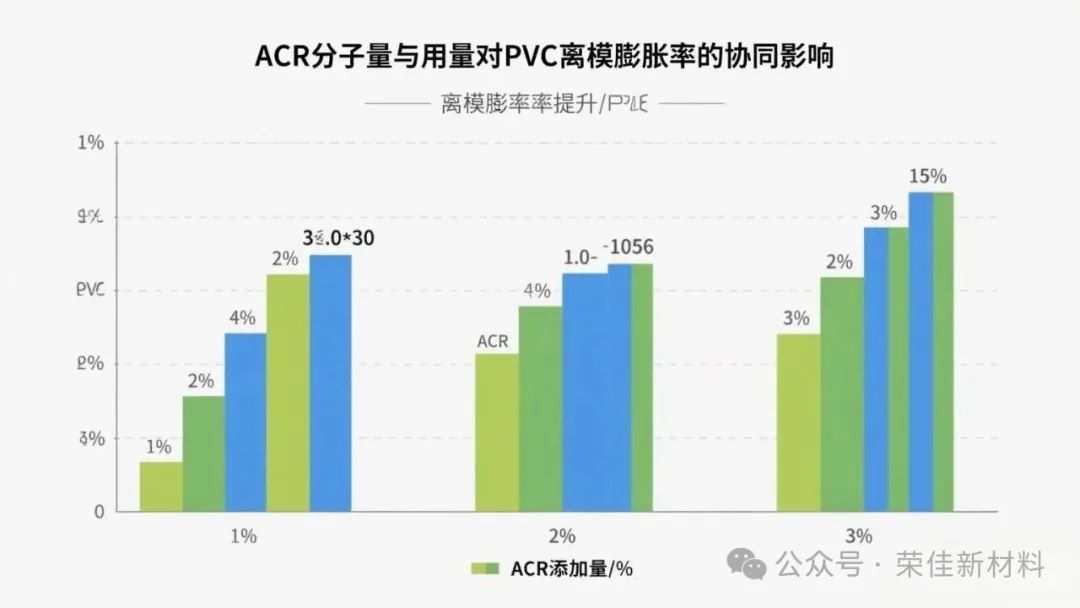

Molecular weight and dosage synergyAs the molecular weight of the additive increases and the dosage increases, the mold release expansion rate becomes higher. For example, ACR with a molecular weight of 3.0×10⁶ increases the expansion rate by 40% compared to pure PVC when added at 2%. Meanwhile, ACR with a molecular weight of 1.0×10⁶ only increases the expansion rate by 15% at the same dosage.

Process Adaptability: During forming, moderate expansion (expansion rate of 10%-20%) helps the parison conform to the mold, improving the uniformity of the bottle's wall thickness. To minimize expansion during extrusion (control within 5%), low molecular weight additives should be selected (Mw < 1.0×10⁶), along with reducing the extrusion speed (shear rate < 100 s⁻¹).

With the increase in both the amount and molecular weight of processing aids, the expansion of PVC upon extrusion molding increases. Within a certain range of molecular weights, the expansion ratio and the logarithm of Mw have an almost linear relationship. When Mw is below 1.0×10⁶The expansion ratio tends to the expansion ratio without added processing aids. At lower molecular weights, the increase in the expansion ratio of PVC upon leaving the mold depends on the molecular weight of the PVC resin.

Test MethodThe expansion ratio (mold outlet diameter/product diameter) at different shear rates is measured using a capillary rheometer, which can precisely match the type of additives with the molding process.

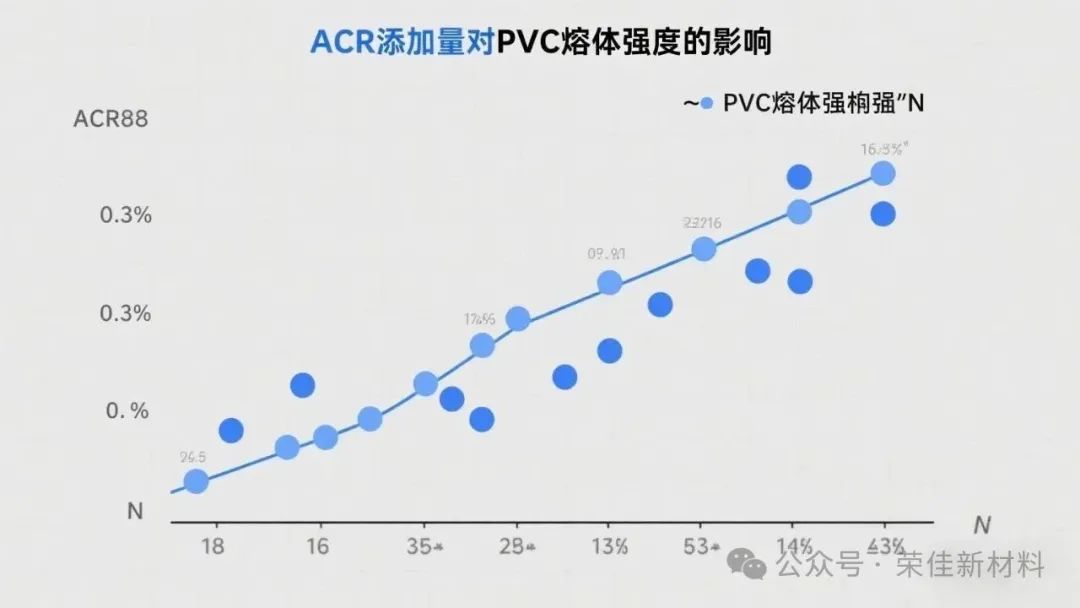

4. Improving Melt StrengthDealing with the challenges of gravity and tensile stress

Melt strengthIt reflects the elasticity and elongation viscosity performance; it is the ability of PVC to resist tensile fracture in a molten state, which is crucial for processes such as blow molding and foaming.

The mechanism of action of processing aids is:

The long chains of high molecular weight additives form stronger molecular entanglements in the melt, enhancing energy dissipation during stretching and reducing parison sagging due to gravity.

The data shows:

- Add 1.2% Mw=3.0×10⁶ ACRAfterward, the PVC melt strength increased from 0.5N to 1.2N, and the wall thickness deviation of the blow-molded bottles can be controlled within ±5% (without additives, the deviation reached ±15%).

- Avoid excessively high molecular weight (e.g., Mw > 5.0×10⁶).Otherwise, it will lead to a sudden increase in melt viscosity, which will instead increase extrusion energy consumption (motor power needs to be increased by more than 10%).

Testing methodsA high-temperature tensile tester can simulate the stretching rate during forming (usually 50-200mm/min) to measure the maximum tensile force at melt fracture and quantify the strength enhancement effect.

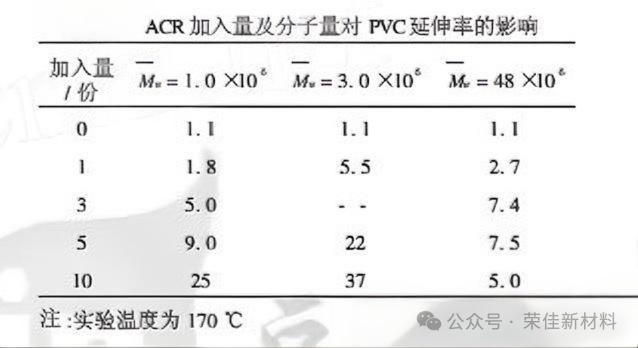

V. Impact on the Elongation Rate:Balancing scalability and production efficiency

In processing applications such as thermoforming, foam extrusion, and blow molding, not only is high melt strength required, but also a certain resistance to elongational or extensional deformation is needed.Elongation rateThe plasticity of PVC melt in thermoforming and foam extrusion is determined.

The impact of processing aids exhibits a "threshold effect.":

The effect is optimal when the molecular weight is moderate.When Mw=3.0×10⁶ ACR is added at a concentration of 1.0%, the melt extensibility is increased by 60% compared to pure PVC, and the cell rupture rate during foam extrusion is reduced to below 5% (compared to 30% without the additive).

Side effects of excessively high molecular weightWhen Mw > 4.0×10⁶, the increase in elongation slows down, but the rise in melt viscosity leads to a 20% increase in roller torque during calendering, making the film surface prone to "wrinkle" defects, necessitating extended heating time (production cycle increases by 15%).

Foam productsIncreasing the elongation rate can make the dispersal of the foaming agent more uniform, reducing the foam density by 10%-15% with the same formulation, thereby achieving lightweight and cost optimization.

The relationship between melt extensibility and the amount of processing aid, and Mw = 3.0 ×10⁶The processing aid Mw = 1.0 ×10⁶ The processing aids are more effective. When the molecular weight is larger, the effect of the processing aids diminishes.

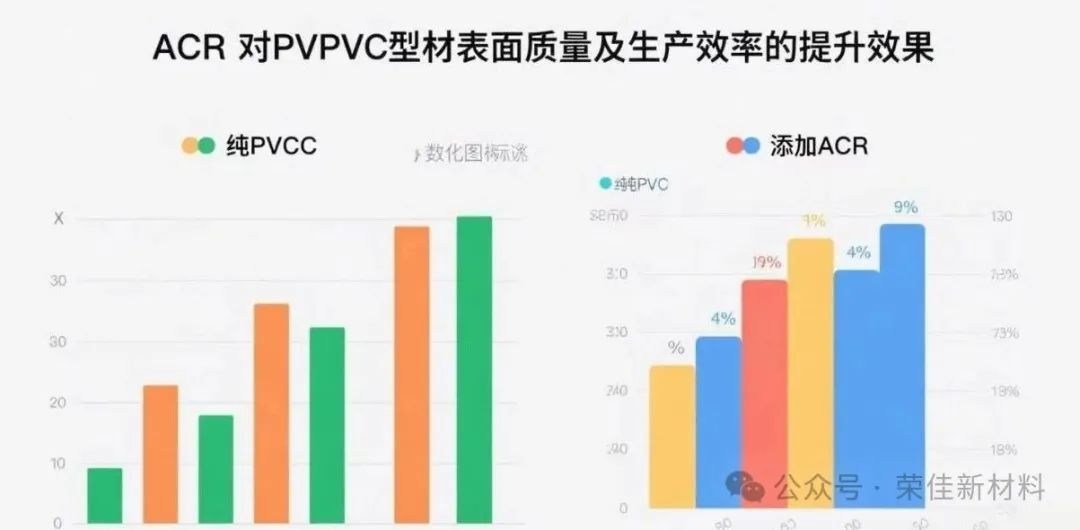

VI. Impact on Surface QualityBreak through shear stress limits and increase yield.

Melt fractureThe main cause of surface defects in PVC products (such as ripples and pockmarks) is that the shear stress exceeds the critical value (usually 0.1-0.3MPa).

Processing aids improve through the following ways::

Increase the critical shear stress of the melt.After adding 0.5% ACR, the critical value increases from 0.15 MPa to 0.25 MPa, and the extrusion speed can be increased by 30% without causing breakage.

- Optimize melt elasticityAdditive molecular chains can absorb part of the shear energy, reducing surface fluctuations caused by elastic recovery.

For example, in the injection molding of door and window profiles, after adding adaptive additives, the shear rate inside the mold increased from 50s⁻¹ to 80s⁻¹, production efficiency increased by 60%, and surface gloss improved from 60GU (gloss units) to 85GU.

7. Influence on Melt ViscosityBalancing Liquidity and Molding Demand

Processing aids, due to their high molecular weight, typically increase the viscosity of PVC melt.However, precise control can be achieved through formula adjustments:

Low additive amount (<1%)Viscosity change is not significant (increase <5%), suitable for injection molding process, to avoid excessive mold filling pressure.

- Regulation of high molecular weight additivesTo reduce viscosity, internal lubricants (such as stearate) can be compounded, or partially incompatible polymers (such as PE wax) can be selected to reduce viscosity by 10%-15% without affecting plasticization.

In practical applications, injection molding requires controlling the melt viscosity between 1000-2000 Pa·s (190°C, shear rate 100 s⁻¹). By adjusting the molecular weight of additives (such as selecting ACR with Mw=1.5×10⁶), precise matching can be achieved to ensure smooth filling and avoid flash defects.

8. Lubrication PerformanceAddress the sticking mold issue to ensure transparency and stability.

ACR-type lubrication additives have both internal and external lubrication functions.The advantage is:

- Low viscosity elasticityLow compatibility with the mold surface can form an isolation layer within the mold, reducing PVC melt adhesion and decreasing demolding force by 20%-30%.

- Non-migratoryThe entanglement force between the molecular chain and the PVC matrix is strong, preventing migration to the surface like traditional paraffin lubricants, thereby avoiding reduced adhesion during subsequent printing and bonding.

Transparency GuaranteeBy selecting additives with a refractive index close to that of PVC (1.52-1.54), such as specific acrylate copolymers with a refractive index of 1.53, the increase in haze caused by light scattering can be eliminated (haze controlled to <3%, pure PVC haze is about 2%).

If brown defects caused by incompatibility occur, two refractive index complementary additives (such as ACR and methyl methacrylate-styrene copolymer) can be blended to control the refractive index deviation of the system within ±0.005 to eliminate color change.

IX. ConclusionMultidimensional collaborative optimization is the key.

The impact of processing aids on PVC processing is not isolated but is governed by their chemical composition, molecular weight, addition amount, and the synergistic effects with other additives (such as fillers and impact modifiers). For example:

When compounded with calcium carbonate fillerThe amount of processing aids needs to be increased (from 0.8% to 1.2%) to counteract the adverse effects of fillers on melt flow.

- With impact modifiers (When used with CPE, a medium molecular weight ACR (Mw=2.0×10⁶) should be selected to avoid a sudden increase in melt viscosity due to excessive entanglement of molecular chains.

Therefore, in the actual formulation design, it is necessary to====Rheological testing(Torque-time curve, melt strength determination) andProcess simulationBalance plasticizing efficiency, rheology, and surface quality.To achieve efficient and high-quality PVC processing, these indicators must be met.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track