The Role of Hot Runner Systems in Reducing Waste and Cycle Time

The plastics industry has always been a source of new ideas, efficiency, and sustainability. Among the numerous technological advancements impacting the industry, hot runner systems have proven to be one of the most powerful. These systems facilitate the way manufacturers approach injection molding by meeting two critical needs: saving cycle time and minimizing the potential for injection molding waste. As global economic pressures demand greater precision in plastic parts, faster turnaround, and more environmentally friendly, sustainable production options, organizations are increasingly focusing their investments on the advantages of hot runners in plastics to remain competitive.

This article will discuss the multifaceted impact of hot runner systems on injection molding efficiency, mold performance, industry-wide mold temperature control methods, mold maintenance procedures, and energy-saving molding practices in modern manufacturing.

Understanding Hot Runner Systems in Injection Molding

The core of any plastic manufacturing business is the ability to produce parts with consistent integrity at the lowest possible cost. Traditionally, cold runner systems have dominated, where plastic resin flows through unheated channels before filling molds and the molds themselves. Nevertheless, these runners leave behind excess material and by-products, prolonging the manufacturing process and increasing inefficiencies in injection molding.

On the other hand, the hot runner system uses heating elements to keep the resin molten as it rises to the cavity. The bypass of the flow channel means that direct gating produces minimal waste and simplifies the process. When combined with appropriately specified injection molding machines, hot runners provide manufacturers with a proven competitive advantage.

Shortening cycle time: competitive advantage

One of the main factors leading manufacturers to implement hot runner systems is the reduction of cycle time. In injection molding, there is no idle time. Cold runner processes require longer cycles because the runner must cool down to be ejected. The use of hot runners reflects a decrease in cooling and cold runners, enabling faster output.

Careful study of industry case studies shows that, due to the installation of hot runner systems, they have been able to reduce cycle times by as much as 30-50%. This is reflected in increased output, full utilization of injection molding specifications, and reduced operating costs. More importantly, the reduction in cycle time also means a faster response to market demand—an important differentiating factor in the automotive, electronics, and medical plastics industries.

Precision and Quality of Plastic Parts

The essence of high-quality manufacturing lies not only in speed but also in precision. Insufficient cooling, inconsistent melt or flow, or mold temperature can often alter the precision of plastic parts. Hot runner systems provide uniform pressure and temperature distribution, as they keep the resin molten at all times and guide it to the cavity.

This consistency results in smoother surfaces, fewer weld line propagation, and the elimination of part defects. Hot runners are absolutely essential for industries such as medical devices because the precision of plastic parts directly impacts patient safety. Additionally, the system's compatibility with high-tech molds ensures high repeatability and consistency, even in large-scale production.

From the perspective of sustainable development: reducing waste in injection molding

Today’s manufacturing industry adopts lean approaches and is environmentally responsible. Reducing waste is one of the greatest advantages of hot runner technology in injection molding. Traditional cold runner systems generate unnecessary waste in the form of excess material, which must either be recycled or discarded, further increasing costs for companies and disrupting the environment.

For the hot runner system as well, there should be no runner from the start, thereby minimizing material waste to the greatest extent possible. This aligns with the broader goal of sustainable plastic manufacturing, enabling companies to meet regulatory requirements and customer expectations. When combined with energy-efficient molding processes, hot runners can lead to a more environmentally friendly industrial cycle with almost no impact on productivity.

Mold Temperature Control: The Hidden Key

Every efficient molding process relies on proper mold temperature control. When the temperature is not controlled, manufacturers may face issues like incomplete filling, part warping, or shrinkage.

The hot runner system keeps the resin at the required temperature before injection, thereby improving control over the mold temperature.

In modern hot runner design, zone heating has also become possible, allowing for adjustments to heating based on the complex design requirements of the mold. This control itself helps improve the efficiency of injection molding and the precision of plastic parts, enabling the production of injection-molded parts that meet stringent tolerance levels without producing costly rejects.

Energy-saving Forming Practice

The plastic industry has long been accused of using energy-intensive business practices. However, by introducing hot runner technology, it can save energy. Hot runners also utilize energy more efficiently, as they direct heat to where it is needed most, whereas cold runners consume energy to regrind or recycle excess material.

More importantly, combined with a set of optimized injection molding machine specifications, the hot runner system reduces the total power consumption per cycle. This integration not only saves utility costs but also contributes to making plastic production in the industry more sustainable.

The advantages of hot runner systems in plastics: a broader perspective.

Using a hot runner in plastic has indeed more advantages than just reducing waste and speeding up cycle times. These include a more efficient raw material structure, less labor required for handling the runners, minimized post-processing costs, and improved cleanliness in the factory. When a company produces millions of products, these profits can lead to significant profitability.

In addition, hot runners also allow for in-depth exploration of advanced mold design options, which is impractical for cold runners. This flexibility enables manufacturers to innovate, meet customized requirements, and enhance their competitive position.

Mold maintenance service: Keep the system efficient.

If not monitored regularly, no technology can perform at its best. Regarding maintaining the hot runner system at optimal performance, mold maintenance service is crucial. Preventive maintenance will keep fixed components such as heating elements, nozzles, and manifolds in good condition, preventing failures that could lead to temporary downtime and potentially result in significant financial losses for the company.

The number of outsourced mold maintenance has also increased, with experts coming to conduct inspections, mold cleaning, and component replacement.

This will provide exceptional reliability, and manufacturers are not limited to optimizing the efficiency of injection molding.

Injection molding machine specifications: aligned with the hot runner system

To achieve optimal results using a hot runner, it is necessary to specify the machine requirements. Various factors, including clamping force, injection size, and injection speed, are crucial for promoting smooth operation. Failing to match the machine's capabilities with the hot runner's requirements may lead to inefficient processes or low precision in plastic parts.

Forward-thinking companies are investing in machines specifically designed to accommodate hot runner molds, further accelerating cycle times and energy-saving molding initiatives.

Market Insights: Hot Runner Systems and the Global Plastics Industry

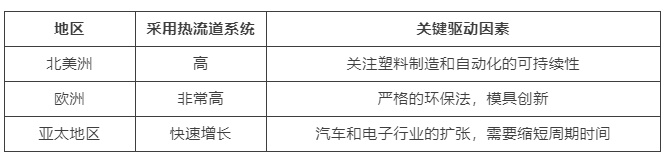

The global plastic market is expected to grow steadily, with hot runner systems being a key factor. According to a report by analysts in this field, the adoption rate of hot runner systems is very high in regions with strict environmental regulations and a growing consumer demand for eco-friendly products.

The increase in market awareness has reinforced the belief that the advantages of hot runners in plastics are no longer optional but rather a key factor for long-term competitiveness.

The Future of Hot Runner Technology

As technology continues to advance, hot runner systems are becoming increasingly intelligent, energy-efficient, and easier to connect. Digital sensors used for controlling mold temperature, artificial intelligence monitoring the precision of plastic parts, and predictive analytics for mold maintenance services are transforming this field.

In fact, the integration of hot runner systems with the concept of Industry 4.0 in the next decade will elevate injection molding performance to a new level, extending the capabilities for cycle time minimization, energy-efficient injection molding, and further sustainability in plastic production.

Hot runner systems are no longer just a means to simplify processes in today's plastic commercial sector. They constitute a pillar of injection molding longevity, enabling shorter cycle times, achieving high precision in molded plastic parts, and taking important steps to reduce injection molding.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track