The most expensive component in new energy vehicles: Why Power Batteries Are So Critical? Analysis of Plastics Material Application

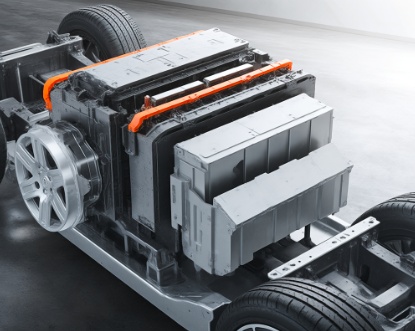

In the cost structure of new energy vehicles, the power battery is the most critical component, with its cost typically accounting for a significant proportion of the total vehicle cost.The proportion of over 30% not only reflects the core position of power batteries in new energy vehicles but also illustrates the dual characteristics of their technical complexity and material costs.

As a vertical platform in the plastics industry, Specialized Plastics World will analyze the value of power batteries, the development of China's industrial chain, the application of key materials, and future technology directions. It will explore why power batteries have become the most expensive component in new energy vehicles and analyze how the plastics involved play a role.

The image is AI-generated.

Power Battery: The Core of New Energy Vehicle Performance and Cost

The value of power batteries goes far beyond their cost proportion; as the core of energy storage and conversion, they directly determine the range, safety, and user experience of new energy vehicles.

Early electric vehicles had a limited range of just a few dozen kilometers due to low battery energy density, making them insufficient for daily needs. With technological advancements, the energy density of power batteries has increased from less than...Increasing from 100Wh/kg to over 300Wh/kg, mainstream models have a range exceeding 400 kilometers, while some high-end models even surpass 1000 kilometers. This is what truly enables electric vehicles to have the potential to replace gasoline vehicles.

Safety is another key indicator for power batteries. Thermal runaway of batteries has been a major cause of spontaneous combustion in new energy vehicles. To address this, the industry has made advancements through material innovations (such as high-nickel ternary cathodes and silicon-based anodes) and structural optimizations (such as...CTP technology balances energy density and thermal stability. For example, BYD's "blade battery" achieves safety performance by preventing single cell thermal runaway from spreading through improved cell structure combined with ceramic thermal pads and a honeycomb design.

Charging efficiency also affects user experience. From the early stages ofFrom the 400V platform to today's 800V and 1000V high-voltage platforms, charging power has increased from 60kW to 350kW. Some models have already achieved "charging for 5 minutes, range of 200 kilometers." This breakthrough relies on the synergistic evolution of battery materials (such as high-conductivity cathodes and thinner separators) and thermal management technologies. For example, Tesla's 4680 battery employs thermal conductive adhesive and liquid cooling structures, which have improved thermal management efficiency by 30%.

China's Power Battery Industry: From Catching Up to Global Leadership

Chinese companies dominate the global power battery market.In 2025, the global market share of power batteries exceeds 68%, with CATL and BYD ranking first and second, respectively, accounting for a combined share of 55.7%. This achievement is attributed to multiple factors:

CATL fromFounded in 2011, the company has focused on the fields of power batteries and energy storage batteries, rejecting the temptation to manufacture cars. It has built technical barriers through a full-chain R&D approach from "materials-manufacturing-application." Its R&D investment in 2024 reached 18.6 billion yuan, with over 43,000 patents. This long-term commitment has laid the foundation for its technological leadership.

Source of the image: Tong Jiren Automobile Research

The automotive-grade sodium-ion battery launched by CATL has an energy density.The battery has an energy density of 175Wh/kg and can maintain 90% of its charge at minus 40°C, with carbon emissions 60% lower than lithium batteries, effectively alleviating the dependency on lithium resources. In addition, its second-generation Shenxing ultra-fast charging battery supports a 12C peak charge (1.3 megawatts), allowing for 80% recharge in 10 minutes, showcasing a breakthrough in fast-charging technology. The dual-core battery technology, through "lithium + sodium" and "lithium + lithium" combinations, balances cost and performance, supporting a 500-kilometer range and 5C fast charging.

As Chinese power battery companies deeply integrate upstream materials (cathode, anode, electrolyte) and downstream car manufacturers through large-scale production (such as CATL globally.For example, BYD has achieved cost reduction through vertical integration, implementing full process control from cell to battery pack, thereby further enhancing its cost advantage.

Plastics in Power Batteries: Functions and Applications

The demand for lightweight, sealing, and safety in power batteries has driven the widespread application of high-performance plastic materials. Although these materials do not directly participate in electrochemical reactions, they play a key role in the reliability and durability of the batteries.

Sealing elementEnsuring battery safety is fundamental, for example,PPS (polyphenylene sulfide) sealing rings can withstand high temperatures of 220-240℃ for extended periods, resist electrolyte corrosion without deformation, and are widely used in battery module sealing to ensure a stable internal environment.

Insulation materialUsed to prevent thermal runaway propagation in battery cells. Aerogel composite film, polyimidePI) Foam and other materials, due to their low thermal conductivity (as low as 0.012W/(m·K) for aerogels) and high temperature resistance (capable of withstanding up to 1200°C), have become the main choices for thermal insulation between battery cells. BYD's "blade battery" employs ceramic insulation pads and a honeycomb structure to prevent the spread of thermal runaway in individual cells, which is a typical example of the application of thermal insulation materials.

Structural support components represented by battery packsResponsible for fixing the position of the cell and bearing vibrations and impacts. Modification.PPO (polyphenylene oxide) and PC/ABS (polycarbonate/acrylonitrile-butadiene-styrene) materials combine strength and toughness. PPO is resistant to high temperatures up to 130°C, while PC/ABS is suitable for thin-walled part molding. CATL's CTP technology enhances volume utilization by 20% by reducing module structures and directly integrating battery cells with polymer supports, exemplifying the optimization of structural support materials.

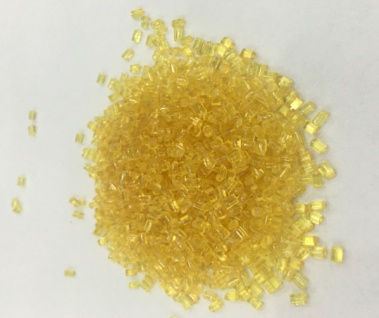

Electrical insulating materialsIn high-pressure environments (For voltages above 800V, it is crucial. Materials such as PPS and PEI (Polyetherimide) are resistant to electric arcs and tracking, ensuring insulation performance. For example, Huawei's AI fast-charging system uses PEI insulation sheets that can withstand 3000V, with a thickness of only 0.2mm, meeting the insulation requirements of high-voltage fast charging.

PEI, image source: Baidu Encyclopedia

Thermal management materialsThermal conductive silicone, phase change materialsPCM (Phase Change Material), etc., are used for efficient heat dissipation and temperature uniformity. Thermal conductive silicone fills the gap between the battery cell and the liquid cooling plate, with a thermal conductivity of 1-5 W/(m·K); the phase change material absorbs heat and melts at 45°C to control temperature rise. Tesla's 4680 battery adopts a structure of thermal conductive adhesive combined with liquid cooling, improving thermal management efficiency by 30%, which is precisely the result of the synergistic effect of thermal management materials.

Packaging and protective materials such as aluminum-plastic film(NylonAluminum foil/PP composite), V0 grade flame-retardant PC, used for pouch cell packaging and hard shell battery casing protection. The thickness of Funeng Technology's pouch cell aluminum-plastic film is 152μm, with a puncture strength of >30N and resistance to electrolyte corrosion for 1000 hours, reflecting a breakthrough in protective performance.

Future Technology Direction: Material Innovation Drives Performance Upgrades

Despite significant advancements in power battery technology, the industry is still exploring more efficient and safer solutions.

Solid-state batteryIt is an important direction for the future, and its sulfides...Polymer solid-state electrolytes have achieved an ionic conductivity of 10^-3 S/cm with an energy density target of 500 Wh/kg. Although mass production may take another 3-5 years, it is expected to completely solve the thermal runaway risk of liquid batteries.

Sodium-ion batteryDue to abundant resources and low cost (lower than lithium batteries)In 2025, CATL will launch a new sodium battery with an energy density of 175Wh/kg, stable performance at -40°C, which will be first applied in commercial vehicles and energy storage fields to alleviate the pressure on lithium resources.

In the production of power batteries,AI-empowered materials research and developmentAccelerate the development of cathodes (such as lithium-rich manganese-based), anodes (such as hard carbon), and electrolytes (such as ionic liquids) through high-throughput computation and machine learning, thereby shortening the cycle from laboratory to mass production for new materials.

In terms of circular economy,Battery recycling (nickel, cobalt, lithium) and secondary utilization (energy storage) become new growth points.CATLThe "battery swapping + recycling" model has covered 100,000 vehicles, achieving efficient resource utilization.

Power batteries as for new energy vehicles"The 'heart' is valuable not only because of its cost proportion but also as a platform for technological integration, driving the cross-disciplinary fusion of material science, manufacturing processes, and energy management. The leading position of Chinese enterprises in the global industrial chain is attributed to continuous investment in technological depth and rapid response to market demands."

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track