The impact of different additive concentrations on the properties of halogen-free flame-retardant toughened reinforced pa66

In the halogen-free flame retardant, toughened, and reinforced PA66 system, the content of various additives is a complex balancing act, where a single change can affect the entire system. Below, I will break down in detail the impact of different additive contents on the key properties of the finished product.

"Seesaw" effect

In plastic modification, there are few additives that "only bring benefits." Most of the time, we are Improving one aspect of performance often leads to a decline in another. Understanding this "seesaw" effect is key to designing formulations.

Component analysis and its influence on content

1. Halogen-free flame retardant

Common TypesAmmonium polyphosphate (APP)-based intumescent flame retardants, hypophosphites (such as aluminum diethylphosphinate), melamine cyanurate (MCA), etc.

Content Impact:

Flame retardancy:Positive correlationTo achieve UL94 V-0 level (usually at a thickness of 1.6mm or 0.8mm), aCritical additive amountIf it is below this amount, the flame retardant effect will not meet the standard or will be unstable; if it is above this amount, the improvement in flame retardancy is limited, but the negative effects increase sharply.

Mechanical properties (strength/rigidity):Negative correlationFlame retardants are mostly inorganic compounds or low molecular weight organic compounds, which have poor compatibility with the PA66 matrix and can disrupt the continuity of the matrix, acting as "stress concentration points." The higher the content, the more pronounced the decrease in tensile strength and flexural strength.

Resilience:Negative correlationFlame retardant particles are rigid particles that can significantly hinder the deformation ability of plastics, leading to a notable decrease in impact strength (especially notched impact strength). This is the main reason why flame retardant PA66 often requires simultaneous toughening.

Liquidity:Complex impactMost flame retardants reduce melt viscosity, but certain types (such as APP) may partially decompose at processing temperatures, producing gases that affect melt uniformity and surface quality.

● Heat distortion temperature:Slightly decreased or basically unchangedThe flame retardant itself has decent heat resistance, but because it weakens the matrix strength, it may lead to a slight decrease in HDT.

Electrical performance:Negative correlationThe ionic impurities in inorganic flame retardants may affect the volume resistivity and dielectric strength.

- Appearance and weather resistance:Negative correlationHigh content can easily lead to surface floating fibers and precipitation (frosting), and certain flame retardants (such as APP) have poor hydrolysis resistance, which may migrate and lose effectiveness over long-term use.

2. Toughening agent

Common typesPOE grafted with maleic anhydride (POE-g-MAH), EPDM (EPDM-g-MAH) and other elastomers.

Content impact:

Resilience:Positive correlation (but with a saturation point)Adding a small amount of toughening agent (such as 5%-10%) can significantly enhance the notched impact strength. However, beyond a certain amount (such as over 20%), the improvement effect slows down, and performance may even decline due to excessive elastomer aggregation.

Mechanical properties (strength/stiffness):Significantly negatively correlatedThis is the biggest "cost" of toughening agents. They can significantly reduce the tensile strength, bending strength, and modulus of the material. The higher the content of the toughening agent, the "softer" the material becomes.

Liquidity:Usually positively correlatedThe elastomer itself has good fluidity, which can improve the processing fluidity of the system.

Heat deformation temperature:Significantly negatively correlatedThe glass transition temperature (Tg) of elastomers is very low, and a large addition can significantly reduce the heat distortion temperature of the material.

Flame retardancy:Usually negatively correlatedMost elastomers are flammable; their addition dilutes the concentration of flame retardants and becomes "fuel" for combustion.Severe deterioration of flame retardant effectThis is the biggest contradiction in flame retardant and toughening formulation design.

3. Enhancer

Common typesChopped glass fiber (GF) is the most mainstream choice.

Content Influence:

● Mechanical properties (strength/rigidity):Positive correlationGlass fiber is the most effective means to improve strength, rigidity, and modulus. The higher the content (usually ranging from 15% to 35%), the better these properties.

● Heat Deflection Temperature:Significant positive correlationFiberglass can significantly increase HDT, allowing the material to maintain its shape at higher temperatures.

Resilience:Complex impact。

Unnotched impact strengthSlight improvement possible.

Gap Impact Intensity:Possibly negatively correlatedThe ends of glass fibers are natural stress concentration points, which, under notch conditions, can easily lead to rapid crack propagation, thereby reducing impact strength. This is why "reinforcement" does not equate to "toughening."

Anisotropy:Positive correlationThe higher the content, the more obvious the issues of uneven shrinkage and warping deformation caused by fiber orientation.

● Processing wear:Positive correlationFiberglass causes severe wear on screws and molds, and the higher the content, the faster the wear.

Flame retardancy:Slight negative correlation or little impact.Glass fiber itself is non-combustible, but the "wick effect" may promote burning and dripping. When a V-0 flame retardant rating is required, a small amount of glass fiber can sometimes help achieve V-0 by carrying away heat through dripping. However, too much glass fiber can hinder the formation of a stable char layer, thereby requiring more flame retardant.

Density:Positive correlationThe density of fiberglass is higher than that of PA66, and the higher the content, the heavier the material.

4. Other additives (lubricants, coupling agents, etc.)

Although the content is small (typically <1%), its role is crucial.

LubricantImprove demolding and reduce energy consumption. Excessive amounts can lead to surface oil stains, affecting appearance and secondary processing (such as bonding and spraying).

● Coupling agent (such as silane coupling agent)To improve the interfacial adhesion between glass fiber and PA66, enhancing strength. Its usage is related to the glass fiber content.

Comprehensive Formulation Design and Balancing Strategy

In actual development, it is necessary to====Application scenarios of the final productTo determine priorities.

Scenario 1: High rigidity, high flame retardancy (such as circuit breaker housing)

→ Strategy:High glass fiber (~30%) + high flame retardant (~20%) + low/medium toughening agent (~5-8%)

ConsiderationPrioritize strength and flame resistance. Sacrifice some toughness, and compensate for brittleness through precise mold design and craftsmanship.

Scenario 2: High toughness, high flame retardancy (e.g., cordless power tool housings)

Strategy:Medium/low glass fiber (~15-20%) + high flame retardant (~20%) + high toughening agent (~15-20%)

ConsiderationThis is the most difficult balance. It requires the selection of an efficient halogen-free flame retardant system and may involve using special toughening agents that have minimal impact on flame retardancy. High levels of toughening agents can significantly reduce strength and HDT, necessitating repeated testing and verification.

Scene 3: Flame Retardant Thin-Walled Products (such as Connectors)

→Strategy:Low glass fiber (~10-15%) + high-efficiency flame retardant (may require >20%) + minimal toughening agent

ConsiderationThin-walled components themselves do not require high toughness, but they require extremely high fluidity and rapid flame-retardant carbonization ability. The focus is on optimizing the flame retardant and lubrication systems.

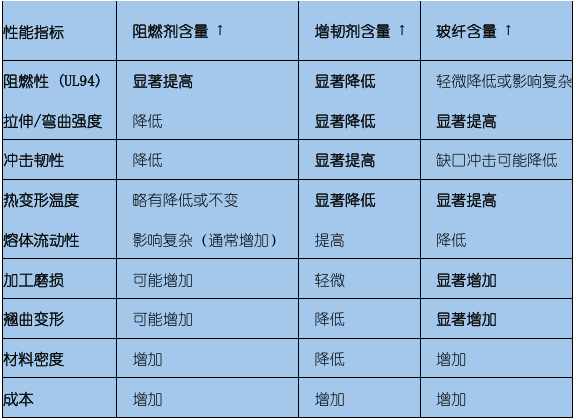

Summary Table

Designing a halogen-free flame-retardant, toughened, and reinforced PA66 formulation is essentially a process ofConstant weighing and compromise.The process. There is no "perfect" formula, only the "most suitable" formula for a specific application. The usual R&D process is: determine the core performance objectives → determine the base of flame retardants and glass fibers → compensate for toughness loss with toughening agents → use other additives to fine-tune processability and secondary performance → verify and optimize through extensive experimentation.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track