The first low-carbon standard in the dairy industry has been implemented, with a requirement for no less than 5% of biodegradable packaging materials as one of the indicators.

Recently, the first low-carbon evaluation technical specification standard for the dairy industry, "Technical Specification for Low-Carbon Evaluation of Dairy Enterprises" (Group Standard No.: T/FDSA 0063-2025), was officially released. This standard was jointly compiled by the Institute of Carbon Neutrality at Peking University, the Certification and Accreditation Technology Research Center of the State Administration for Market Regulation, Inner Mongolia Mengniu Dairy (Group) Co., Ltd., Heilongjiang Feihe Dairy Co., Ltd., Shanghai Jinsinan Financial Research Institute, the Feed Research Institute of the Chinese Academy of Agricultural Sciences, the School of Food and Health at Beijing Technology and Business University, Junlebao Dairy Group Co., Ltd., and the Beijing Entrepreneurs' Foundation for Environmental Protection. The standard will come into effect on April 15, 2025, and is applicable to low-carbon evaluation activities for dairy enterprises. It specifies the basic requirements, evaluation principles, evaluation procedures, evaluation methods, and evaluation reports for low-carbon evaluation of dairy enterprises.

The Technical Specification for Low Carbon Evaluation of Dairy Product Enterprises has established four major categories of indicators: management system, green energy, low carbon supply chain, and emission reduction performance.

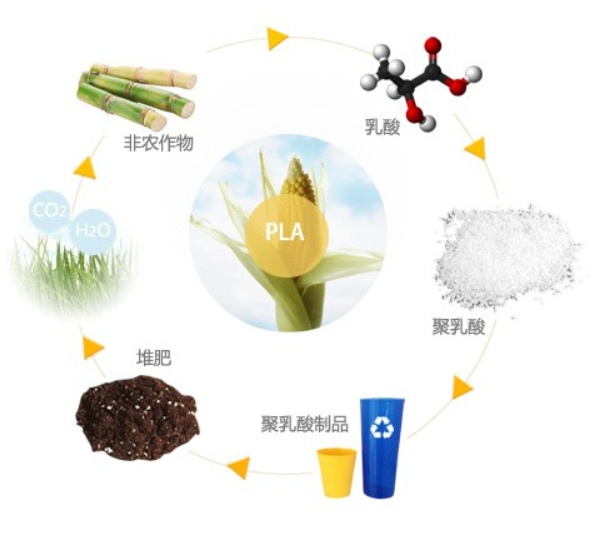

Sustainable packaging accounts for a significant proportion in the evaluation form. "Using no less than 5% biodegradable or no less than 40% recyclable packaging materials" is specified as a specific indicator in the "Technical Specification for Low-Carbon Evaluation of Dairy Enterprises" group standard, included within the low-carbon industrial chain.

"Sustainable packaging is an important area that dairy companies have been exploring and practicing. Companies reduce the environmental impact of packaging materials through R&D of new packaging materials and optimization of packaging design," said Xu Qinyi, a researcher at the Institute of Carbon Neutrality at Peking University.

Regarding the evaluation of "sustainable packaging," Xin Bin, Vice President of SGS China, stated that SGS focuses on the selection of packaging materials, the rationality of packaging design, and the construction of packaging recycling systems. In terms of material selection, it examines whether companies prioritize the use of sustainable materials such as paper and biodegradable plastics, which have relatively lower environmental impacts during production and disposal. In terms of packaging design, it assesses whether simplification and lightweighting have been achieved, minimizing the use of packaging materials while ensuring the safe transportation and storage of products.

"There is much room for adjustment in packaging in the future," said Gao Anping, General Manager of Mengniu's Environmental Sustainability Development. First, the cost-performance ratio is not ideal. Currently, we are experimenting with 4R1D sustainable packaging, but the cost of choosing biodegradable materials is three to five times that of traditional materials. Moreover, the barrier properties of these materials are relatively poor, which may lead to a shorter shelf life. For example, with the plant-based Dream Cap, although the market has shown some recognition, the cost of single packaging has increased by thirty cents. Therefore, it is necessary to continuously increase production and sales volume to gradually reduce this cost.

Secondly, the recycling rate of packaging materials is extremely low. Domestic recycling data shows that the recycling rate of packaging materials is less than 30%. The main reason for the low recycling rate is that the public generally lacks awareness of the recycling value of packaging materials. The revenue from recycling a packaging material is between 0.15 to 0.20 yuan. Currently, the recycling system is not yet complete and is mainly concentrated in large cities like Shanghai and Hangzhou, making it difficult to implement in other cities.

Again, there are numerous industry barriers. It is difficult to coordinate the interests of parties such as users, manufacturers, and environmental protection departments. For example, the state prohibits the recycling and use of certain materials, but companies sometimes find it hard to ensure complete compliance. Therefore, many difficulties exist in the advancement process. Gao Anping believes that if we want to achieve sustainable packaging in the future, integration needs to be prioritized first. Through management platforms, data should be automatically generated, and differences can be identified through data analysis while finding the balance between investment and returns. This requires achieving through big data analysis and empowerment.

"We recommend that enterprises, from the perspective of long-term development, increase investment in the research and procurement of sustainable packaging materials, collaborate with professional packaging design companies to optimize packaging design solutions, actively coordinate with upstream and downstream enterprises, establish a comprehensive packaging recycling system, jointly promote the green transformation of the entire dairy industry chain in the packaging sector, better respond to the growing green consumption demands of consumers, and contribute to the transition of society towards a green lifestyle," said Xin Bin.

Promoting low-carbon transformation in the dairy industry cannot be achieved without policy support. "We hope to rely on government supervision to ensure that the standards already established can be effectively implemented, allowing companies to fairly compete under unified standards. At the national level, support can be given for the establishment of new standards, including policy subsidies, setting up funds, and so forth. We also hope that the government can open up some innovation platforms for us to participate in. Overall, I hope that both the government and enterprises can work together to achieve these goals across all dimensions," said Gao Anping.

Green development in China has been guided in part by the trend toward green, low-carbon economics. The importance of green and low-carbon development was once again emphasized in this year's government work report, which proposed the coordinated advancement of carbon reduction, pollution control, increased green spaces, and economic growth. It also called for accelerating the comprehensive green transition of the economy and society, and outlined specific goals for green and low-carbon development.

In recent years, China's dairy production level has significantly improved, and dairy consumption continues to grow rapidly, with the dairy product manufacturing industry developing steadily. The "China Dairy Quality Report (2024)" shows that in 2023, there were 654 dairy processing enterprises above the scale, with main business income of 462.09 billion yuan, and the output of dairy products reached 30.546 million tons.

At the same time, dairy product manufacturers are also one of the major sources of carbon emissions in the agri-food system. In 2024, the global average temperature exceeded the pre-industrial level by 1.5 degrees Celsius for the first time. Global climate change has intensified, and food systems account for about one-third of global emissions, with the dairy industry contributing a significant proportion of greenhouse gas emissions. The transformation of the dairy industry towards green and low-carbon practices is becoming a trend.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track