Technical features of sichuan zhongwang large high-end petrochemical polyolefin extrusion granulation unit

Sichuan Zhongwang Technology Co., Ltd. is a technology-oriented enterprise formed by a group of technicians who were among the first in China to manufacture and apply twin-screw extruders. Over nearly 30 years of manufacturing and applying co-rotating parallel twin-screw extruders, the company has accumulated a wealth of valuable experience. Through its own exploration and by referencing advanced foreign technologies, it has overcome the bottleneck issues in extruder transmission technology. As a result, Zhongwang Technology's extruder products boast advantages such as high torque, high efficiency, low energy consumption, high cost-effectiveness, and low overall production costs. Their main technical indicators far exceed those of domestic peers. Since commercial production began, the company has maintained its leading position in domestic technology as one of the leaders in the field of domestic extruders and has kept in sync with the technical standards of top international extruder equipment manufacturers.

Innovative Achievements

Sichuan Zhongwang Technology's Strength and Breakthrough in Large Extrusion Granulation Unit

Innovation achievements:

1. Continuously develop new functional structures and components.

The continuous optimization of the structural parameters of mixing components can be adapted to meet the mixing requirements of more resin grades.

High torque technology for gear transmission, high reliability, and uniform design technology are more suitable for the processing operations of high-viscosity materials and large-scale requirements.

4. Key component materials and process technology.

Advantages:

Durability, stability, and efficiency comparable to top foreign brands.

The frequency of unplanned shutdowns per year is less than five times, which is comparable to Japan's JSW and Germany's Coperion.

Sichuan Zhongwang Technology Strength and Breakthrough in Polymer Post-Processing and Devolatilization Reaction Unit

Innovation Achievements:

1. Twin-screw devolatilization extruder

2. Multi-stage Vacuum Control

Advanced Stripping + Decentralized Distribution Devolatilization

The residual solvent can be reduced from 5%–40% to 300 ppm.

Transmittance ≥ 93%, Yellowness Index ≤ 0

Application scope: POE, EPDM, FDPE, POM, PMMA, POM, PPC, and other metallocene solution process polyolefin products.

Design capacity: Single line annual output of 50,000 to 200,000 tons

Representative Performance:

Single-line thousand-ton-per-year POE devolatilization extrusion granulation unit

Single-line annual production of 50,000 tons PPC devolatilization granulation unit

Single-line PMMA devolatilization and granulation unit with an annual output of 80,000 tons

Single-line 200,000-ton-per-year solution process FDPE (octene copolymer) devolatilization extrusion pelletizing unit

Sichuan Zhongwang: Strength and Breakthrough in the Localization of Spare Parts for Imported Extrusion Granulation Units

Innovative Achievements:

The original replacement of the barrel of German and Japanese large extrusion granulation units to enhance wear resistance and corrosion resistance, repair, and optimize redesign and manufacturing.

2. Original replacement and optimized redesign and manufacturing of screw elements and mandrels for German and Japanese large extrusion granulation units.

Upgrading the inner surface hardness of the cylinder (using advanced laser welding repair technology from German Yasen University of Technology to enhance the cylinder's...

The service life can be increased by more than five times.

The latest process extrusion granulation unit's old barrel is repaired and upgraded, using laser welding alloy for efficient repair of the barrel with worn inner bore.

Main products

01Large petrochemical complete set extrusion granulation unit

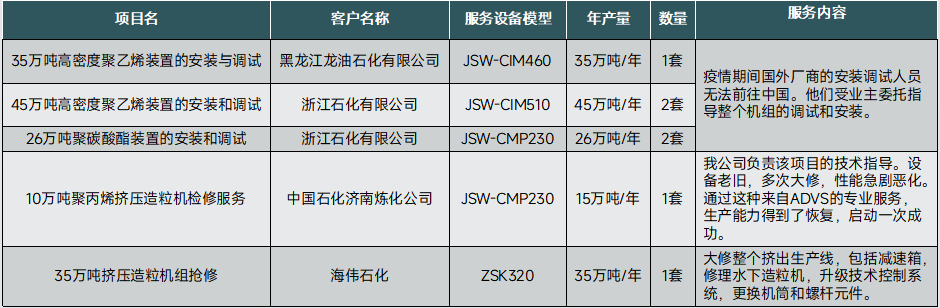

Since 2017, clients such as Dongfang Hongye, Luqing Petrochemical, Hongji Petrochemical, and Haiwei Petrochemical have continued to repurchase our company's large-scale petrochemical extrusion granulation production lines.

02China National Petroleum Jilin Petrochemical Chlorinated Sulfonated Polyethylene Project

Model: YRT-450/20 counter-rotating differential thickener (screw diameter 480mm) + counter-rotating twin-screw (screw diameter 120mm) + co-rotating twin-screw extruder combination for continuous devolatilization, extrusion, and granulation, to reduce the raw material with a solid content of 8% to a final product at PPM level.

03Devolatilization Equipment--Co-rotating Twin-screw Reactive Extruder

Applied to: polymer solvent devolatilization, maleic anhydride grafting, reactive extrusion of special engineering plastics (PI, PPA, PMMA, POE, etc.).

04The processing and manufacturing of large mandrels and barrels is jointly produced by Lanzhou Lanshi Group, a renowned enterprise in China.

Our company uses electroslag remelting (ESR) deoxidized steel ingots to forge with a ten-thousand-ton hydraulic press, employing a flexible forging process to manufacture spindle shafts up to 20 meters in length, thereby solving the issue of spindle strength.

Material benchmarking against German grades, with the most advanced forging process, mandrel specific torque ≥13.6 N·m, performance comparable to German ZSK and Japanese CMP series.

05The processing and manufacturing of large machine barrels

Our company's barrels can use high-quality nitrided steel combined with the laser cladding technology from YaShen University of Technology, with a cladding wear-resistant alloy layer of over 2mm, ensuring a service life of more than 20 years.

06The processing and manufacturing of large imported extruder threaded components and wear parts.

Our company can undertake the processing of threaded blocks with a maximum diameter of 500mm and the localization of imported extruder vulnerable parts. The selection of materials and forging standards (ring forging process) for screw elements are benchmarked against German standards to prevent abnormal wear and extend service life.

07A well-known domestic petrochemical company

The imported ZSK320 large extruder unit had been experiencing gearbox noise and vibration issues, which remained unresolved despite repeated repairs by the original manufacturer and other domestic companies over a period of two years. This resulted in long-term low production capacity. Upon receiving the maintenance task, our company responded immediately and completely resolved the issue in just 13 days, restoring production capacity to normal levels.

08A large foreign petrochemical enterprise

Due to the failure of the imported ZSK177 gearbox which was beyond repair, a special trip was made to China to commission our company to manufacture a replacement gearbox in situ. We formed a professional technical team for design and manufacturing, and dispatched experienced assembly personnel to provide on-site guidance for installation and commissioning. After the equipment was started and put into operation, it achieved 100% of the original factory's production capacity, earning high praise and recognition from the customer.

09JSW 230X-12AW gearbox maintenance

In 2021, for the maintenance of the JSW 230X-12AW gearbox of a large domestic chemical group, our company, as a professional service provider, offered comprehensive technical guidance, saving a substantial amount of maintenance costs for the client.

10Import of extrusion machine equipment and gearbox maintenance and replacement

The POM equipment of CNOOC Tianye Chemical (Italian Maris TM223) experiences periodic abnormal vibrations and current fluctuations during the polymerization reaction process.

By modifying the gearbox structure, the issues of severe wear on the gearbox output splines, reduced bearing life, severe wear on the splines at the connection between the mandrel and the gearbox, and severe wear on the cylinder and threaded block caused by periodic strong vibrations have been resolved. This addresses the key technical challenge of long-term equipment operation. At the same time, components such as the cylinder, mandrel, and threaded block have been replaced. Through the modification of the gearbox structure, the problems caused by periodic strong vibrations have been resolved.

11Import extruder overhaul

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track