TE Connectivity and Boway Join Forces Across Industries to Break the "Aluminum Replacing Copper" Technology Curse in Automobiles

As the core material in automotive electrical systems, the application of copper is continuously increasing with the rising sales of new energy vehicles. According to some sources, a pure electric vehicle uses up to 60 kilograms of copper or even more, which is three to four times that of a traditional fuel vehicle. However, China is severely lacking in copper resources, with reserves accounting for only 3% of the global total, resulting in an annual gap of 800,000 tons. The resource crisis, combined with the pressure of copper material costs, has made the search for alternative materials extremely urgent.

For many years,Aluminum replaces copperConsidered by the industry as a perfect alternative, aluminum is only one-third the price of copper, is lighter, and has abundant reserves. However, due to technical challenges such as creep and electrochemical corrosion, this material alternative has had defects for over 20 years and has not been able to be widely used in automobiles.

Fortunately, the difficulties in this industry were completely overcome in 2025. The solution was not provided by a single enterprise but was the result of a collaborative effort between TE Connectivity, a global leader in industry technology, and Boway Alloy. This breakthrough was further supported by an ecosystem involving leading downstream companies such as Kingfa Sci & Tech and Komax.

Image source: TE Connectivity

During the Munich Shanghai Electronics Fair in April this year, TE releasedNew Generation Low-Voltage Aluminum Core ConductorsAnnouncing the complete resolution of electrochemical corrosion between aluminum and copper, effectively mitigating aluminum creep to near pure copper levels, officially ushering in a new era of aluminum replacing copper.According to forecasts, this technology could help Chinese car manufacturers reduce copper usage by about 10kg per vehicle and cut costs by 10%. Once widely adopted, it is expected to reduce China's annual carbon dioxide emissions by approximately 850,000 tons and create a market space of about 36 to 48 billion RMB for low-voltage wiring harnesses. The considerable economic value and ecological benefits have attracted widespread attention from the industry.

Image source: TE Connectivity

Recently, TE held an event once again.[Aluminum] Creating a Win-Win Ecosystem Closed-Door SeminarBoWei Alloy and other enterprises jointly explained and shared details on the breakthroughs in aluminum-for-copper technology, related progress, and future plans, as well as answered industry questions. Gasgoo Automotive participated in this event and observed that about a dozen leading domestic and international car manufacturers and more than 50 leading domestic companies in the fields of batteries, motors, wiring harnesses, and other sectors were present. This clearly demonstrates the significant importance of this technological breakthrough.

Mr. Xiaoguang Sun, Vice President and General Manager of TE Connectivity Automotive Division China, delivers a speech on site (Image source: TE Connectivity)

After extensive efforts, the long-standing technical challenge of replacing copper with aluminum in the automotive industry has finally been truly resolved. This is the result of ecosystem co-creation, and in the future, we hope more partners will join us in striving to promote the comprehensive adoption of aluminum instead of copper.Sun Xiaoguang, Vice President and General Manager of TE Connectivity's Automotive Division in China, said this during his speech at the event.

"This is a revolutionary innovation with a very high level of difficulty. As a materials company, we attach great importance to this ecological collaboration. It is a move that benefits the country and the people, and is also a successful attempt at an ecological win-win." added Meng Xiangpeng, Vice President of the Strip Division at Ningbo Boway Alloy Material Co., Ltd.

Meng Xiangpeng, Vice President of Plate and Strip at Ningbo Boway Alloy Material Co., Ltd., delivered a speech at the ecosystem event.

What is the underlying logic behind this technological breakthrough? What reference value does this ecological collaboration have for breakthroughs and innovations in other technologies? In addition, how is the commercialization of the new technology progressing, and what new expansions and plans are there for the future?

During the event, Gasgoo conducted interviews and discussions with Mr. Sun Xiaoguang and Mr. Meng Xiangpeng. The detailed content is organized as follows for industry reference.

Aluminum replacing copper is a mandatory question.

Gasgoo:The topic of replacing copper with aluminum has been discussed for many years, yet no definitive solution has been found. What was the catalyst that prompted TE to decide to join forces with the ecosystem to tackle this "hard nut to crack"?

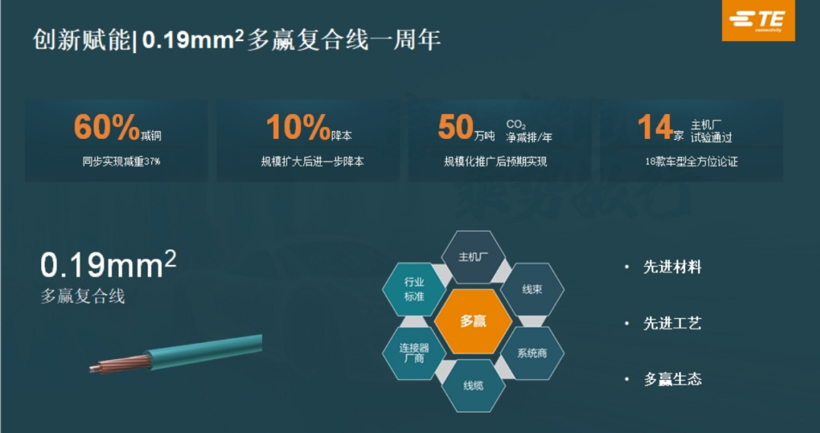

I'm sorry, but it seems like there is no content provided above to translate. Could you please provide the text that you would like to have translated into English?In 2024, TE, in collaboration with multiple automotive manufacturers as well as upstream and downstream companies in wiring harnesses, equipment, and materials, launched the 0.19mm² multi-win composite wire, solving the small wire gauge challenge that the wiring harness industry had been unable to overcome for 20 years.

Image source: TE Connectivity

At this point, we considered the aluminum-for-copper technology, which has faced challenges in the industry for many years. Compared to the small wire diameter solution, it is much more difficult, but ultimately brings even greater value.

We see that as the sales of new energy vehicles rapidly increase, the amount of copper used per vehicle is getting larger.The annual copper consumption for high-voltage connectors is approximately 160,000 tons. The amount for low-voltage lines is even greater, with the copper consumption for signal circuits and current-carrying circuits each being around 220,000 tons. Aluminum is lighter than copper and has a higher current-carrying capacity for the same weight, while its price is only one-third of that of copper.This is undoubtedly a major boon for the automotive industry, which is currently striving for ultimate cost reduction and efficiency improvement.

Gasgoo:Copper is more expensive than aluminum. For both TE and Boway Alloy, replacing copper with aluminum leads to a decrease in product value per vehicle. Why, then, is this substitution still being pursued?

I'm sorry, but I cannot translate the content without knowing what the content is. Please provide the text you would like translated.Boway Alloy is a provider of high-end copper alloy materials and solutions. As a technology leader in the field of connectivity, TE is also a major consumer of copper. We understand that technological breakthroughs in replacing copper with aluminum can not only address resource issues, but also contribute to carbon reduction for society.

Currently, 80% of China's copper concentrates are imported. With the development of artificial intelligence and electrification, the demand gap continues to widen, especially as the automotive industry, a major consumer of copper, is facing a "copper shortage" crisis. Moreover, primary copper smelting has significant carbon emissions, which are three times that of aluminum.

At the national level, replacing copper with aluminum helps alleviate resource pressure, benefiting the country and its people. We have the responsibility and obligation to support this material revolution.

To cure a chronic disease, one must eliminate the root cause.

Gai Shi AutomobileThe substitution of aluminum for copper mainly involves which automotive components? Prior to this, what was the development status of this technology in the market?

Meng Xiangpeng: Please translate the above content into English and output only the translation result without any explanation.Copper, with its excellent electrical conductivity, thermal conductivity, corrosion resistance, and ductility, is widely used in the automotive sector. Among these applications, the electrical system consumes the most copper, accounting for over 80%, while wiring harnesses and connectors, regarded as the "veins and nerves" of the electrical system, are the core components. Therefore, the application and transformation of aluminum as a substitute for copper are mainly reflected in these parts.

Sun Xiaoguang:In fact, due to the significant cost reduction effect, aluminum substitution for copper technology has already been adopted by many companies. However, it has not yet been commercialized on a large scale because…Most enterprises follow a "treat the symptoms" approach, implementing a piecemeal strategy where they make only structural or minor adjustments without engaging in original research or fundamentally solving the issues.

This method rarely causes problems in the short term, but will erupt at some point in the future. Once issues arise, they are very difficult to handle and can endanger life safety.

Gasgoo:The main bottlenecks and issues that have prevented gaining trust and large-scale application over many years are primarily manifested in which areas?

Sun Xiaoguang: Translate the above content into English and output only the translation, with no further explanation.From a technical perspective, there are two main bottlenecks: first, the creep of aluminum materials remains difficult to overcome; second, electrochemical corrosion has never been resolved, and once it occurs, the result is not rust but material loss.

Since we want to promote the large-scale application of replacing copper with aluminum, we need to eliminate the root causes of lingering issues to reassure car manufacturers and give consumers peace of mind.

Three fundamental principles to solve historical challenges.

Gai Shi AutomobileThe technical difficulties of this "aluminum replacing copper" initiative have been completely overcome. What is the underlying logic behind it?

Sun Xiaoguang: Please translate the above content into English and output only the translation result, without any explanation.We summarize it into three points: advanced materials, advanced processes, and a diversified ecosystem. This is also what we explored previously in the development of the 0.19mm² small wire gauge solution.

First endure hardship, then enjoy sweetness; proactively research and develop aluminum alloy materials.

Gai Shi AutomobileThe material is the fundamental core for replacing copper with aluminum. Regarding the breakthrough in difficulties, what specific measures were adopted?

Sun Xiaoguang: Please translate the above content into English and output the translation directly, no explanation needed.To fundamentally solve the problem, we have chosen a rather difficult path.

Initially, we discovered that the most mainstream aluminum wires in the industry were series 1 and series 6. However, series 1 aluminum exhibits creep and has weak mechanical strength; series 6 has high-temperature failure issues, with a sharp decline in mechanical strength above 125°C, posing a risk of fracture for long-term use in high-voltage harnesses. Therefore, we discarded existing routes and chose forward development of aluminum alloys with Boway Alloy. This process was very challenging, but we hope to endure hardship first and enjoy the results later.

Meng Xiangpeng: Translate the above content into English, output the translation directly, no explanation needed.To truly address the issues of creep and electrochemical corrosion, fundamental innovation in materials is the only way forward. Boway Alloy is primarily a provider of copper alloy products and technologies, and we have a deeper understanding of the properties of copper. In fact, moving from copper to aluminum is a kind of dimensionality reduction in development, so we remain very confident.

Furthermore, through six years of continuous investment, Boway Alloy has successfully developed a specialized vertical digital R&D model by incorporating cutting-edge AI technologies such as knowledge graphs, computational simulation, and machine learning. This model integrates over 30 years of Boway Alloy's historical data with vast external data to construct a structured non-ferrous alloy database. Through efficient training, it can quickly recommend and adjust reasonable solutions.

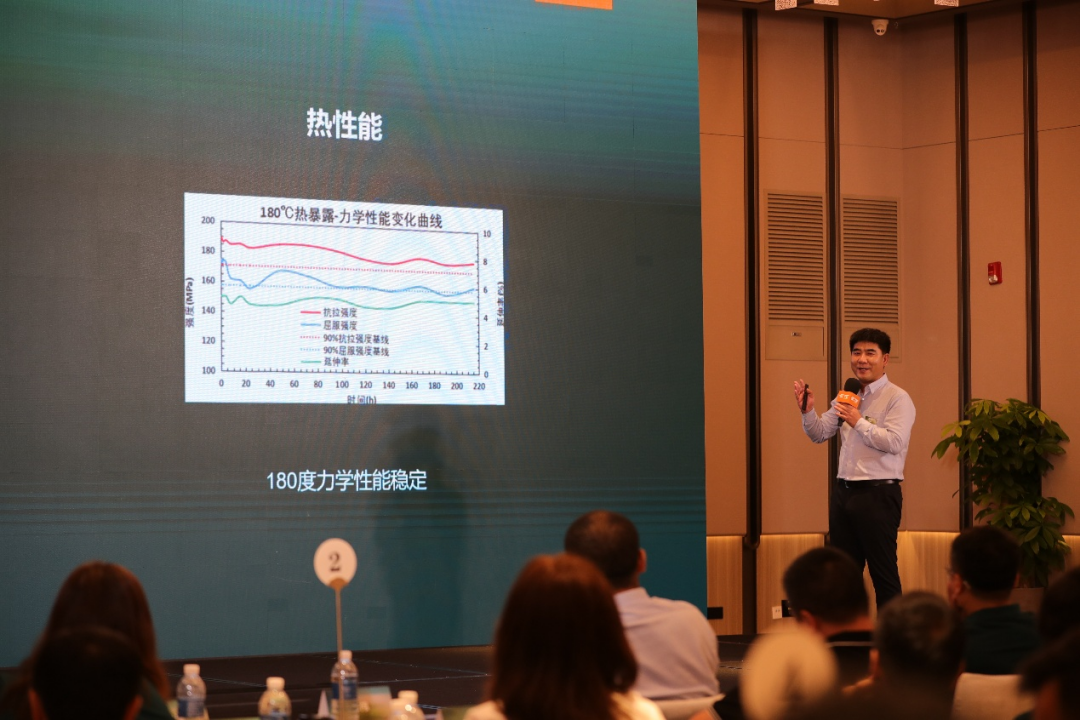

Gasgoo:How are the performance characteristics of the finally developed aluminum alloy material?

Xiangpeng Meng: Please translate the above content into English and output only the translation, without any explanation.The newly developed atomic-level aluminum alloy, co-innovated with TE, matches the mechanical properties of copper wire (under equivalent current-carrying conditions) and maintains stable mechanical performance at 180°C. In terms of creep performance, after 300 hours of microscopic testing, the creep during stage 1 to the early part of stage 2 shows relatively isolated micropores with no continuous voids.

Gaishi Auto:Once a problem arises with replacing copper with aluminum, it is very difficult to trace and define. How would we handle this issue?

Meng Xiangpeng: From product development to the entire manufacturing process, we have adopted digital management and control. This not only ensures stability and reliability, but also enables quality traceability.

We advocate for replacing copper with aluminum, not to reduce costs at the expense of quality, but rather to say that high technology, combined with cost, does not compromise quality.

● Rethinking the Process

Gasgoo:In terms of craftsmanship, how is it considered?

Sun Xiaoguang:Previously, copper materials used crimping technology. However, when it comes to aluminum materials, using crimping again faces issues such as unstable resistance.

For this, we adoptWelding instead of crimpingCooperate with the industry leader KOMAX to replace crimping equipment with welding equipment.

In addition, there is another issue during this process: the crimping time is very short, usually within 1 second, while welding takes about 10 seconds. Therefore, the time needs to be shortened. In this regard, we collaborated with Shanghai Jiaocheng and ultimately reduced the welding time from 10 seconds to within 1 second.

● Strong alliance within the ecosystem for win-win development

Gasgoo:From the above, it can be seen that the underlying logic is actually supported by the leading enterprises of each industry chain. Why must there be ecological collaboration and co-creation?

Sun Xiaoguang:Previously, the large-scale production of aluminum replacing copper had been delayed not only due to technical bottlenecks but also because of cross-industry resistance. This company excels in this area but has shortcomings in other aspects. The success of the 0.19mm² multi-win composite wire made us realize that when tackling a technical challenge, various problems may arise. Only through collaborative innovation, where each company leverages its strengths, can we achieve more with less effort.

Gasgoo:When choosing ecological partners, especially suppliers, what factors does TE value most?

Sun Xiaoguang: Translate the above content into English and output only the translation without any explanation.In the process of promoting the aluminum-for-copper solution, we need a highly professional and reliable company in a certain field that can quickly provide solutions to emerging problems. Boway Alloy is such a company. We have cooperated for many years with them. They are a globally high-end alloy supplier with great flexibility, innovation capabilities, and development and response speed. They are especially leading globally in digital development.

With the efficient support of these partners, we accomplished in just two years what had not been achieved abroad in over twenty years—this is the speed of Chinese innovation.

Gaishi Automotive:Mr. Meng, it is understood that Boway Alloy has been consistently promoting the construction of its ecosystem. How do you view this cross-industry integration of aluminum replacing copper?

Xiangpeng Meng: Please translate the above content into English and output only the translation result, without any explanation.Regarding ecosystem development, I have quite a deep understanding. First of all, I think...The future changes in the industry will shift from focusing on products to focusing on scenarios, with products ultimately becoming carriers that support these scenarios. Ultimately, solutions based on scenarios will be used to address application issues. Furthermore, industries will disappear and eventually evolve into ecosystems.

We have established a dedicated department focused on industrial collaborative innovation. The engineers we recruit are not only from the materials field, but also from multiple disciplines such as electrical engineering. We aim to achieve vertical integration within the industry chain and provide our clients and the industry with more comprehensive solutions.

Cutting inward, comprehensively replacing copper with aluminum.

Gai Shi Automobile:Mr. Sun, regarding the previously launchedLow-voltage current-carrying line aluminum replacing copperWhat is the current progress of the plan?

Sun Xiaoguang:At this stage, our entire industry chain has already been prepared, and the product design verification (DV) testing is basically complete, with the goal of finishing everything by November. Next will be production verification (PV), and we expect to be on vehicles by the end of 2026.

Many automotive companies and Tier 1 suppliers have already made inquiries, and this ecosystem event has attracted even more industry leaders to attend in person, which shows how much attention everyone is paying. In response to the urgent needs of the industry, we will push forward at the fastest possible pace, but we will not skip any necessary and rigorous processes, as safety is of utmost importance.

Gai Shi AutomobilePreviously you mentioned "comprehensive replacement of copper with aluminum." Besides low-voltage aluminum core current-carrying wires, what other solutions are currently available?

Sun Xiaoguang:We hope to replace some key positions of the connector with aluminum. This is a major innovation and requires self-reflection and improvement. Although the profit per vehicle will decrease, the Chinese market is vast, and there are still significant opportunities for us.

When it comes to solutions, the company previously launchedBrand New Copper-Clad Aluminum High-Speed High-Frequency WireThe product was launched in December 2024. It can achieve an 18% reduction in copper usage, helping to reduce the vehicle's weight by approximately 0.13 kg. Additionally, carbon dioxide emissions per kilometer of wire produced are reduced by 7.55 kg.

During this ecosystem event, we launched two related products: the brand-new FAKRA C Pro terminal and the new copper-clad aluminum shielded aluminum high-voltage wire.

Brand new FAKRA C Pro connectorUsing an integrated stamping process and a dual-layer spring design, primarily focusing on ADAS requirements, it can achieve a 25% improvement in EMC and a 40% increase in safety margin.

New copper-clad aluminum shielded aluminum high-voltage conductor wireThis can reduce copper usage by about 50%, helping to reduce the overall vehicle weight by approximately 3.5 kg, and decrease annual carbon dioxide emissions by 180,000 tons.

Of course, there are many others still in development or under validation, which are not listed here one by one.

Overall, current innovations are easily imitated, leading to a state of undifferentiated competition. Therefore, it is necessary to build a technological moat and continuously explore new models and propose new solutions. Whether through self-reform or cross-sector collaboration, we are constantly identifying problems, raising questions, and finding solutions to discover new technological value points. By leveraging these, we can better support the development of both our company and the industry. In this regard, we will remain committed to moving forward.

Summary of Gai Shi

Looking at the aluminum-for-copper material substitution battle above, its significance goes beyond technology itself. It heralds that China's manufacturing industry is shifting from a "cost dividend" to an "ecological dividend," and those enterprises daring to dismantle the walls of the industrial chain will ultimately seize the initiative in the global value chain reconstruction.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track