Sumitomo Chemical Makes Breakthrough: Direct Ethanol-to-Propylene Production! Plastics Prices Weakly Fluctuate Today, Some Vary by 10-200

Sumitomo Chemical's Major Breakthrough: Direct Production of Propylene from Ethanol!

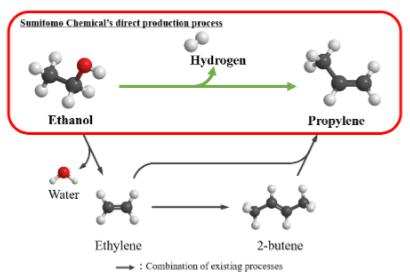

On August 20, Sumitomo Chemical announced that it has successfully constructed and launched a pilot facility using its proprietary new process to produce propylene directly from ethanol. This innovative technology is expected not only to reshape the raw material landscape of the petrochemical industry but also to be closely linked to the future development of the plastics industry.

Innovative craftsmanship, breaking traditional boundaries

In Japan, the production of propylene has traditionally relied on naphtha, a fossil resource. However, the new process introduced by Sumitomo Chemical differs from other methods that use ethanol to produce propylene, as it eliminates intermediate steps such as the production of ethylene, allowing for the direct production of propylene in a single step. This unique technological approach greatly simplifies the production process, resulting in reduced production costs. Furthermore, hydrogen is produced as a byproduct during the production of propylene. If bioethanol is used as a raw material, the hydrogen will also have a biological origin, undoubtedly offering new possibilities for the production of clean energy.

Ethanol feedstock, ushering in a new chapter of sustainability

Ethanol, as a highly promising raw material, has a wide and sustainable range of sources. Biomass such as sugarcane and corn can be used to produce ethanol. Additionally, non-food materials like pulp and, more recently, combustible waste—a research hotspot—can also become the "cradle" of ethanol. Compared to traditional fossil raw materials, these sources of ethanol have obvious environmental advantages. With continuous technological advancements, the industrialization process of large-scale ethanol production from materials such as combustible waste is on the horizon. Against the global backdrop of advocating for sustainable development, the importance of ethanol as a substitute for petrochemical raw materials is increasingly prominent.

Propylene, as a fundamental chemical raw material, is a core upstream component for various engineering plastics. For instance, propylene can be processed to produce acrylonitrile, which is then used to manufacture engineering plastics like Nylon 66; its derivatives can also participate in the synthesis of high-performance polyesters. If Sumitomo Chemical successfully commercializes the technology to produce propylene directly from ethanol, it will provide a "green source" for its engineering plastics supply chain—reducing fossil dependency and lowering carbon emissions throughout the lifecycle from the raw material stage. This not only enhances the environmental competitiveness of its existing products but also lays the foundation for developing new types of green engineering plastics, thereby further consolidating its leading position in the high-end materials market.

Sumitomo Chemical has long been an industry benchmark in the field of engineering plastics, with several of its products occupying significant market positions due to their high performance. Its liquid crystal polymer (LCP) "SUMIKASUPER" is widely used in high-end fields such as 5G communications and automotive electronics, thanks to its excellent high-temperature resistance, chemical corrosion resistance, and dimensional stability. The polyethersulfone (PES) material, with its outstanding heat resistance and mechanical strength, has become a key raw material for medical devices and aerospace components.

2. Today's Plastic Prices

(The above is comprehensively compiled from the New Material Research Society and Dayi You Plastic.)

【Copyright and Disclaimer】This article is the property of PlastMatch. For business cooperation, media interviews, article reprints, or suggestions, please call the PlastMatch customer service hotline at +86-18030158354 or via email at service@zhuansushijie.com. The information and data provided by PlastMatch are for reference only and do not constitute direct advice for client decision-making. Any decisions made by clients based on such information and data, and all resulting direct or indirect losses and legal consequences, shall be borne by the clients themselves and are unrelated to PlastMatch. Unauthorized reprinting is strictly prohibited.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track