Study on the impact of polyurethane-glass fiber composite modification on asphalt material performance

Keywords

Asphalt, as the main material for road construction, is widely used in pavement laying due to its excellent fluidity, workability, and low cost.[1-2]However, with the continuous increase in traffic volume and the impact of extreme weather conditions, traditional asphalt tends to soften at high temperatures and crack at low temperatures, leading to poor rutting resistance and insufficient fatigue resistance. This limits the lifespan and safety of asphalt pavements.[3-4]To enhance the performance of asphalt, modified asphalt materials have gradually become a research focus. Polyurethane (PU) is widely used in asphalt modification due to its excellent elasticity, wear resistance, and anti-aging properties.[5-6]However, single polyurethane modified asphalt still has certain limitations in high-temperature stability and low-temperature crack resistance.[7-8]Glass fiber (GF) has high strength and good dispersion, which can enhance the rutting resistance and fatigue performance of asphalt. The combined use of polyurethane (PU) and glass fiber (GF) not only fully utilizes the elasticity of polyurethane and the reinforcing effect of glass fiber but also improves the high-temperature stability, low-temperature crack resistance, and durability of asphalt, thereby enhancing the overall performance of asphalt pavements.[9-11]This article aims to study the performance of glass fiber-reinforced polyurethane (GFPU) modified asphalt through experiments, analyzing the effects of different modification ratios on the high-temperature performance, low-temperature performance, rutting resistance, and fatigue resistance of asphalt, and exploring its application prospects.

01

Raw Materials and Test Methods

1.1 Raw materials

The experiment used 70# Foshan Shell asphalt. The polyurethane used is MDI (isocyanate)-based polyurethane, which has good thermal stability, elasticity, and adhesion. The selected glass fiber is chopped glass fiber with a length of 6 mm and a diameter of 10 μm, which possesses good dispersibility and reinforcing effects, effectively enhancing the asphalt's crack resistance, rutting resistance, and fatigue resistance. A suitable amount of solvent and dispersant was also used in the experiment to help uniformly disperse the polyurethane and glass fiber in the asphalt.

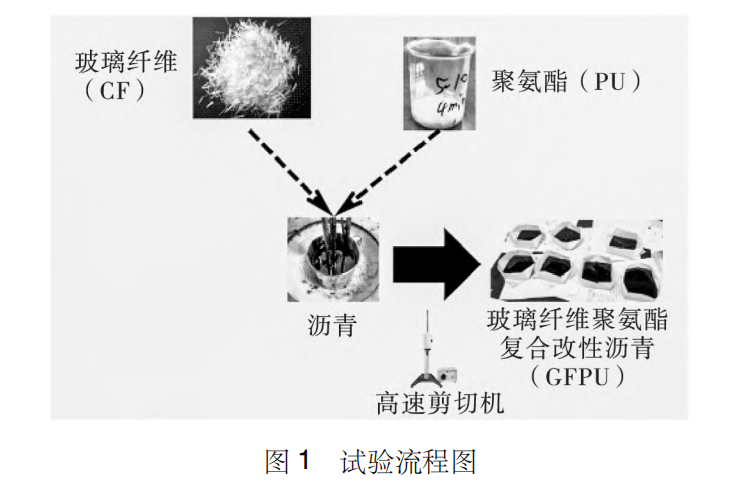

1. Preparation of Modified Asphalt

The preparation process of modified asphalt includes mixing polyurethane composite fiberglass materials with matrix asphalt, using different amounts of polyurethane composite.

1. Preparation of 3 modified asphalt mixtures

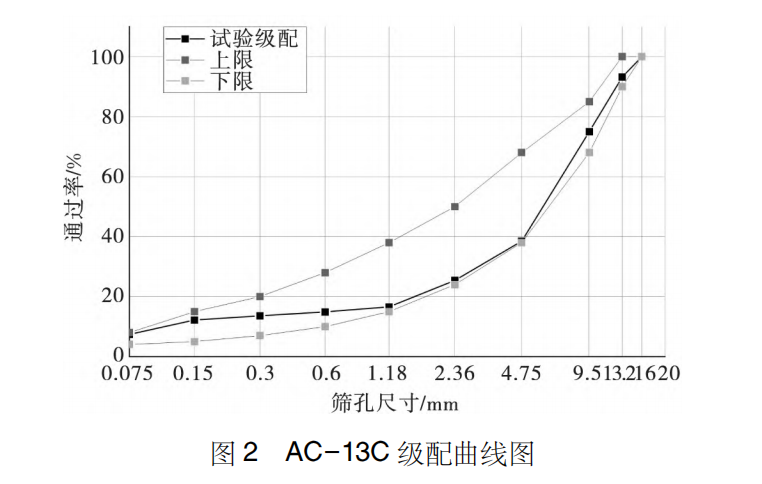

According to the "Technical Specifications for Construction of Highway Asphalt Pavement" (JTG F40—2004)[13]The preparation process of modified asphalt mixture follows the traditional hot-mix asphalt production process. (1) According to the AC-13C grading requirements, as shown in Figure 2, select appropriate coarse aggregates, medium aggregates, and fine aggregates, and dry them to an appropriate moisture content; (2) Mix the prepared modified asphalt with 5%, 10%, and 15% polyurethane and 5% glass fiber with the aggregates, stir evenly at a temperature of 160℃ to ensure a good combination of modified asphalt and aggregates, resulting in different modified asphalt mixtures. After the mixture is completed, perform performance testing using the Marshall method and other test methods.

1. 4 Test Plan

This study conducts a series of performance tests on modified asphalt and modified asphalt mixtures according to the "Test Methods of Asphalt and Asphalt Mixtures for Highway Engineering" (JTG E20—2011).

1. 4. 1 Three Major Indicators Test

Penetration test: Measure using a penetrometer, with a standard needle under a load of 100 g at 25 ℃ ± 0.1 ℃ in a water bath. Measure the penetration after 5 seconds. Softening point test: Use the ring-and-ball method, measuring with a standard asphalt ball under a heating rate of 5 ℃/min. Ductility test: At a stretching speed of 5 cm/min, test the ductility length of the asphalt sample at a temperature of 25 ℃ until it breaks.

1. 4. 2 Fluorescence Microscopy Observation

Cut the asphalt samples into smooth small pieces using a cutting mechanism, and observe their internal structure under a fluorescence microscope at 400x magnification. Record the distribution of polyurethane and glass fibers as well as the interface bonding condition.

1. 4. 3 Dynamic Shear Rheology (DSR) Test

Prepare modified asphalt samples in the form of circular discs with a diameter of 25 mm and a thickness of 1 mm. At a temperature of 64 °C and a loading frequency of 10 rad/s, record the complex modulus (G*) and phase angle (δ) to evaluate the high-temperature rheological properties of the asphalt.

1.4.4 Low Temperature Splitting Test

Prepare a cylindrical specimen with a diameter of 150 mm and a height of 50 mm. Cure it at a temperature of -10 ℃ for 4 hours to ensure uniform internal temperature. Apply tensile stress using a universal testing machine until the specimen splits and fails, with a loading rate of 50 mm/min. Record the maximum splitting force to evaluate the low-temperature crack resistance.

1. 4. 5 Flooding Marshall Test

The specimen dimensions are the same as the standard Marshall specimen, with a diameter of 101.6 mm and a height of 63.5 mm. The molded Marshall specimens are soaked in a water bath at 60°C for 48 hours, then immediately subjected to the Marshall stability test to determine the stability after immersion. The loading rate is 50 mm/min. The Marshall apparatus is used to apply the load until the specimen fails, and the difference in stability before and after immersion is measured to assess water stability.

1. 4. 6 Unconfined Compressive Strength Test

Using standard Marshall specimens with a diameter of 101.6 mm and a height of 63.5 mm, the tests were conducted using an unconfined compression method. A universal material testing machine was employed to apply the load at a standard loading rate of 50 mm/min until the specimens failed. The test temperature was 25 ℃, aimed at evaluating the compressive strength of the mixture.

1.4.7 Splitting Fatigue Test

Using cylindrical specimens with a diameter of 150 mm and a height of 50 mm, conduct tests at a constant temperature of 20°C with a constant repeated stress pattern. The loading frequency is 6 Hz, with a maximum loading stress of 0.5 times the splitting tensile strength. Cycle the loading until the specimen experiences splitting failure, and record the fatigue life (number of cycles) to evaluate the fatigue resistance of the mixture.

02

Experimental Results and Analysis

2.1 Three Major Indicators Test

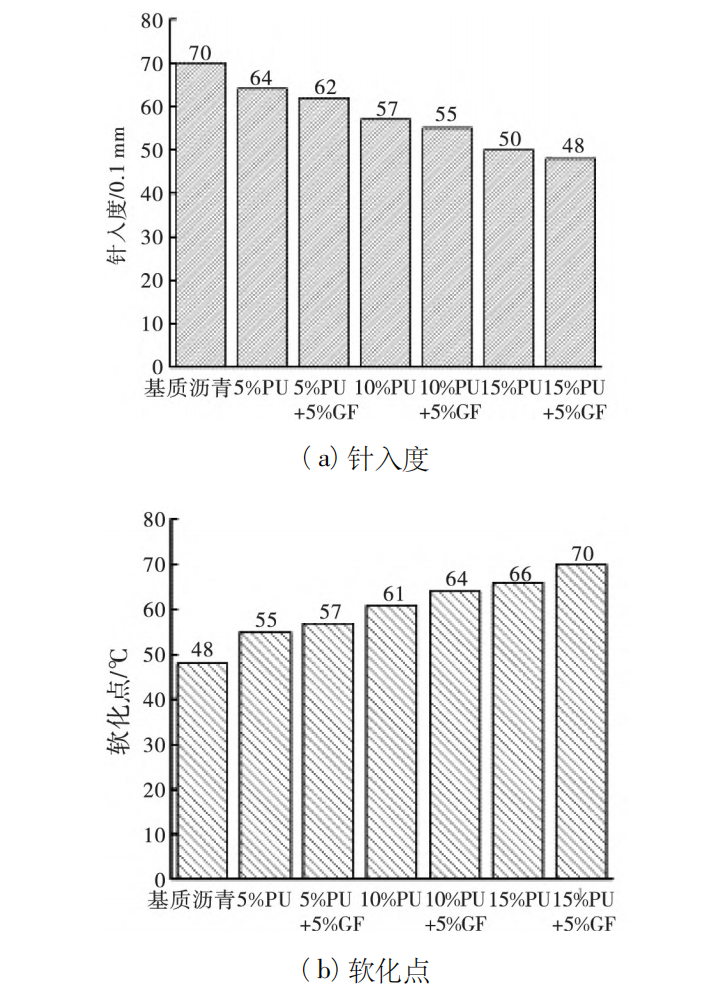

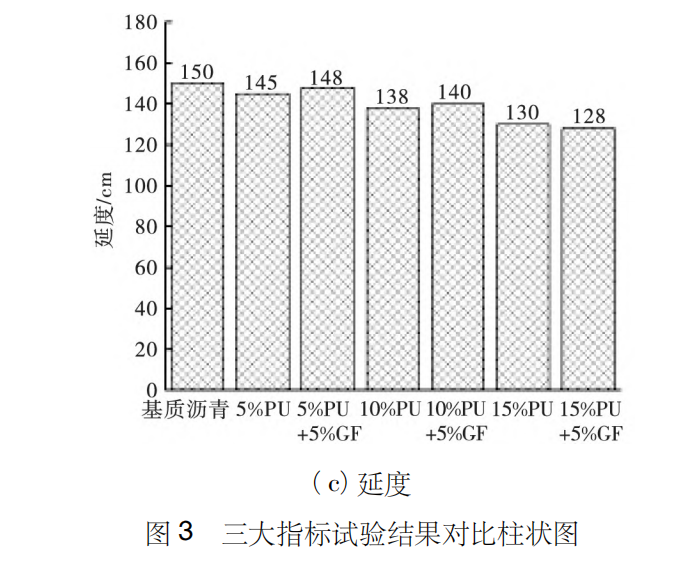

The addition of polyurethane significantly increased the softening point of the asphalt and reduced the penetration and ductility, as shown in Figure 3.

Figure 3 shows the experimental results indicating that the penetration of modified asphalt significantly decreases with the increase in polyurethane content, reflecting a significant improvement in the hardness and high-temperature stability of the asphalt. The upward trend in the softening point suggests that as the cross-linked structure of polyurethane and the reinforcing effect of glass fibers gradually increase, the flow resistance of the modified asphalt at high temperatures improves. In the single polyurethane modification group, the ductility gradually decreases with the increase in content, indicating that its flexibility is somewhat affected. However, in the composite modification group, the addition of glass fibers effectively mitigates this trend, and its ductility is better than that of the single modification group. This may be due to the formation of a skeletal network structure by the glass fibers in the asphalt, providing constraint and support to the asphalt molecules, reducing the possibility of crack propagation, and thereby enhancing the overall flexibility and crack resistance of the asphalt.

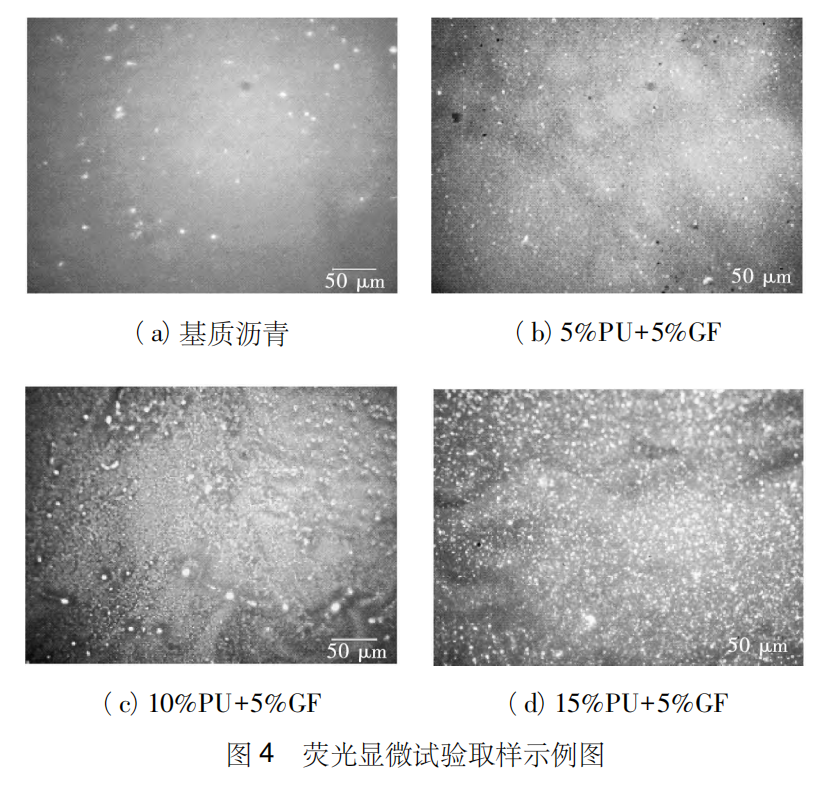

2.2 Fluorescence Microscopy Test Analysis

Samples of the prepared glass fiber polyurethane modified asphalt were taken to observe their dispersion, and the results are shown in Figure 4.

Observing Figure 4, it can be seen that the glass fibers are uniformly distributed in the asphalt, forming a synergistically enhanced network structure with the polyurethane. As shown in Figure 4(d), the fiber network is denser, indicating a significantly enhanced support effect on the asphalt framework.

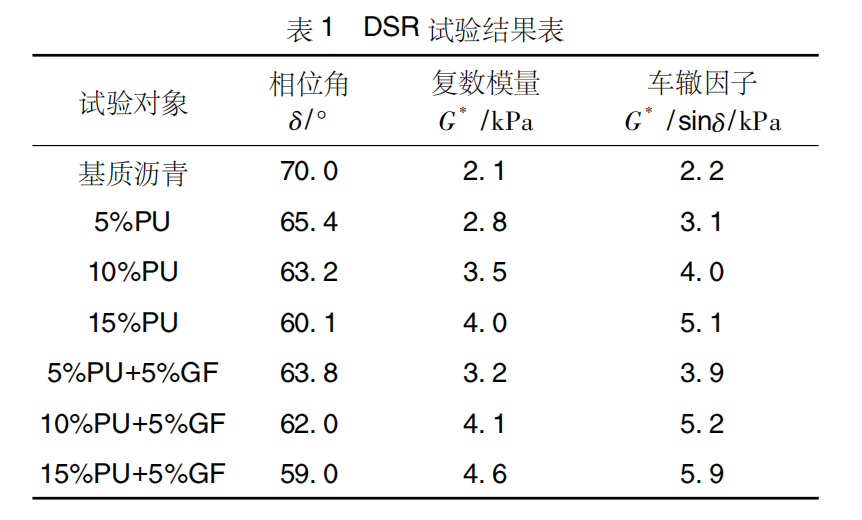

2.3 Dynamic Shear Rheology (DSR) Analysis

The complex modulus (G*) and phase angle (δ) of different samples at a temperature of 64 ℃ were measured using a dynamic shear rheometer, and the rutting factor (G*/sinδ) was calculated. The results are shown in Table 1.

The test results show that the phase angle of base asphalt is relatively large at high temperatures, indicating that it is mainly viscous, with high flowability and weak rutting resistance. After modification with single polyurethane, the phase angle gradually decreases, while the complex modulus significantly increases, suggesting that polyurethane improves the elasticity of asphalt through cross-linking, enhancing its anti-rheological properties. In the composite modification group, with the addition of glass fibers, the phase angle further decreases, and the G*/sin δ value significantly increases, especially in the 15% PU+5% GF group, where the rutting factor reaches 5.9 kPa, higher than the 5.1 kPa of the single 15% polyurethane group. This indicates that the reinforcing effect of glass fibers and the cross-linking effect of polyurethane form a synergistic effect, jointly improving the high-temperature rutting resistance of asphalt while optimizing its viscoelasticity.

2.4 Mixture Performance Testing

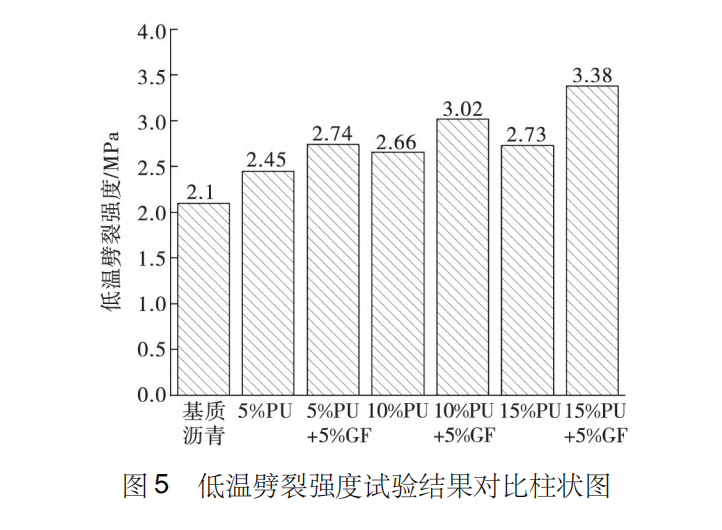

2.4.1 Low Temperature Performance Test

The results of the low-temperature splitting test are shown in Figure 5. It can be seen from Figure 5 that as the amount of polyurethane increases, the splitting strength gradually improves. This is because polyurethane enhances the toughness and crack resistance of asphalt at low temperatures. Compared to the single polyurethane modification group, the composite modification group has higher splitting strength, especially the 15% PU + 5% GF group, which reached 3.38 MPa, an increase of 23.8% compared to the 15% PU modified asphalt. The addition of glass fiber improves the crack resistance of the mixture at low temperatures by dispersing low-temperature stress and preventing crack propagation. This result indicates that the composite modified mixture has significant advantages in enhancing the low-temperature performance of the mixture.

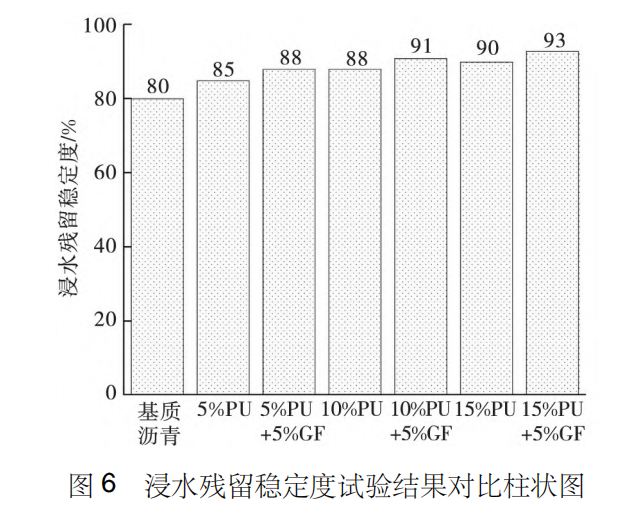

2.4.2 Water Immersion Marshall Test

The results of the immersion Marshall test are shown in Figure 6. As can be seen from Figure 6, the residual stability of the single polyurethane modified group gradually increases with the increase in dosage, reaching 90% for the 15% PU group. The residual stability of the composite modified group is even higher, especially for the 15% PU + 5% GF group, which reaches 93%, demonstrating excellent resistance to water damage. The glass fiber, through its dispersion and high strength, constructs a more stable skeletal structure, while enhancing the water resistance of the mixture. The crosslinking action of polyurethane improves the bonding strength between the asphalt matrix and the aggregate, and the synergistic effect of the two significantly enhances the water stability of the mixture.

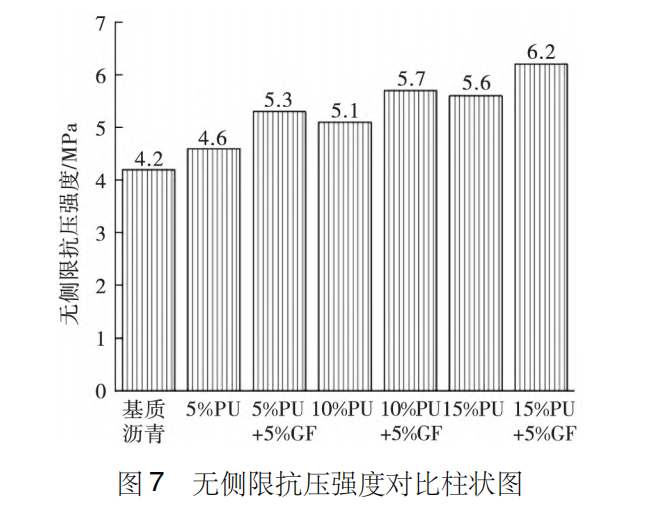

Unconfined compressive strength test 2. 4. 3

The results of the unconfined compressive strength test are shown in Figure 7. From Figure 7, it can be seen that the compressive strength of the matrix asphalt is 4.2 MPa, and with the increase in polyurethane content, the compressive strength gradually increases. In the group with single polyurethane modification, the compressive strength reaches 5.6 MPa at 15% PU, indicating that the cross-linking effect of polyurethane effectively enhances the compressive capacity of the asphalt. The compressive strength of the composite modified group is further improved, especially in the 15% PU + 5% GF group, where the compressive strength reaches 6.2 MPa, an increase of 47.6% compared to the matrix asphalt. This is due to the formation of a skeletal support structure by the glass fiber in the asphalt, which can effectively bear and disperse compressive stress, thus significantly improving the compressive performance of the mixture. The synergistic effect of polyurethane and glass fiber further optimizes the mechanical properties of the asphalt.

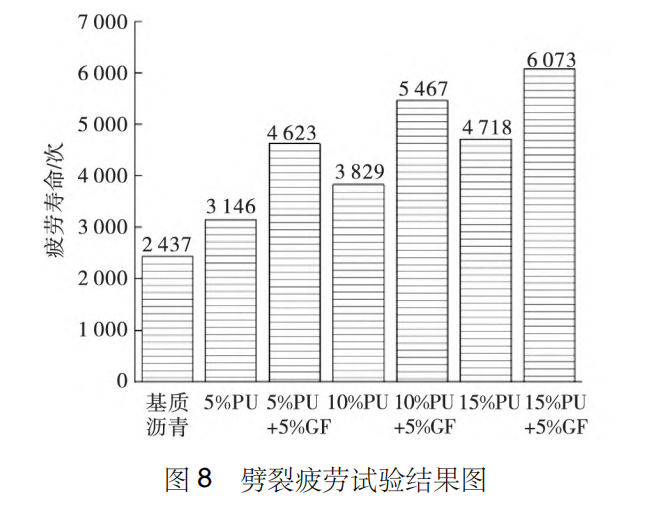

2. 4. 4 Splitting Fatigue Test

The experimental results shown in Figure 8 indicate that the fatigue life of the matrix asphalt is 2,437 cycles, demonstrating its limited fatigue resistance. In the polyurethane-modified group, as the amount of polyurethane increased, the fatigue life gradually improved, indicating that polyurethane enhanced the elasticity and durability of the asphalt through its chemical cross-linking. In the 15% PU modified group, the fatigue life reached 4,718 cycles, showing a significant improvement in fatigue resistance.

In the composite modification group, the fatigue life is generally higher than that of the single polyurethane modification group. Particularly in the 15% PU + 5% GF group, the fatigue life reached 6,073 cycles, which is about 2.5 times higher than that of the base asphalt. This improvement is attributed to the reinforcing effect of the glass fibers in the mixture, effectively suppressing crack initiation and propagation. Additionally, the flexible and elastic characteristics of polyurethane in synergy with the high strength of glass fibers help maintain good integrity and durability of the material under repeated loading.

Overall, the fatigue life of the composite modified group exhibits some variability, reflecting the unevenness in the microstructure and fiber distribution of the material during the tests. This randomness is also unavoidable in actual pavement applications. However, in terms of both crack resistance and durability, the composite modified group demonstrates superior comprehensive performance, especially at high dosage levels where the effect is most pronounced.

03

This study shows that the composite modification of polyurethane and glass fiber significantly enhances the high-temperature stability of asphalt, with a noticeable increase in the softening point. The high-temperature anti-rheological performance of the composite modification group is superior to that of the single polyurethane modification group, demonstrating stronger rutting resistance. This modification method provides effective technical support for road construction under high-temperature climatic conditions.

The low-temperature splitting strength and fatigue life of composite modified asphalt are significantly improved. Particularly, when the proportions of glass fiber and polyurethane are 5% and 15% respectively, the material shows excellent flexibility and crack resistance under low-temperature conditions, while the fatigue life is increased by approximately 2.5 times compared to base asphalt, indicating that composite modification significantly enhances the low-temperature crack resistance and durability of asphalt mixtures.

Fiberglass improves the strength and toughness of asphalt through physical reinforcement, while polyurethane provides better viscoelasticity through chemical crosslinking. The synergistic effect of the two results in modified asphalt exhibiting excellent comprehensive performance in terms of high and low temperature resistance, fatigue resistance, and water damage resistance. Therefore, polyurethane composite fiberglass modification is an effective and feasible method for asphalt modification, suitable for various harsh climate and traffic conditions.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track