Study on high-temperature corrosion resistance of modified polyaniline water-based ceramic coating

01

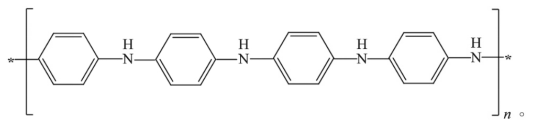

Polyaniline (PANI), as a conductive polymer, is composed of conjugated π bonds and can be transformed from an insulator to a semiconductor or conductor through chemical or electrochemical doping. It is gaining attention due to its unique electrochemical properties, environmental stability, and adjustable physical and chemical properties. It is commonly believed that in its intermediate oxidation state (EB) (Figure 1), it exhibits excellent tunable doping performance. Through heterogeneous doping, it can be converted to EB salt, becoming the most stable conductive doped state (ES state). Hydrophilic modification can effectively improve poor solubility and rheological properties, while also allowing the acquisition of composite materials with multiple functionalities.

Figure 1: Structure of PANI in its EB state

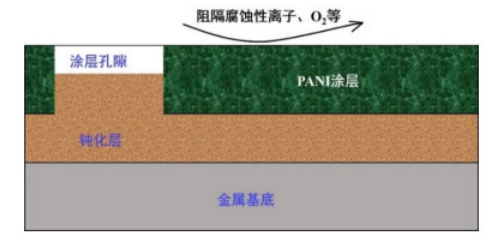

The main anti-corrosion mechanism of polyaniline (PANI) is physical shielding and anodic protection. Figure 2 illustrates the anti-corrosion mechanism of PANI. Physical shielding means that PANI directly obstructs the contact between corrosive substances and oxygen with the metal substrate. In corrosive environments, due to PANI's good conductivity and electrochemical activity, it can quickly restore the passivation layer on the metal surface through anodic oxidation reactions. Specifically, the potential of PANI is higher than the oxidation potential of the metal substrate but lower than the reduction potential of oxygen. The electrons released from the oxidation of the metal substrate can reduce the conductive PANI in its ES state, while the reduced PANI can transfer electrons to oxygen, thereby oxidizing itself back to the ES state. This repeated redox reaction of PANI can accelerate the formation of the passivation layer at the interface between PANI and the metal. This process is known as PANI's anodic protection process. On the other hand, hydrophilic modification of PANI not only improves its compatibility in water-based coating systems, but the doped hetero groups also have corrosion inhibition effects, forming a protective layer on the metal surface and further enhancing the anti-corrosion effect.

Figure 2 Schematic diagram of the anti-corrosion mechanism of PANI

Montmorillonite (MMT) is a layered silicate mineral belonging to the montmorillonite group of minerals. Its chemical structure consists of two layers of silicate tetrahedra sandwiching a layer of aluminum oxide octahedra, forming a typical 2:1 layered structure. The layers are connected by van der Waals forces and ionic bonds, with an interlayer spacing of 1-2 nm, allowing polymer monomers to easily insert. It has a high cation exchange capacity, good swelling properties, and adsorption ability. Using it as a carrier, nanocomposite materials prepared through in-situ synthesis can enhance the mechanical properties and thermal stability of the material. Additionally, utilizing the self-suspending properties of montmorillonite improves the homogeneous dispersion of the material in the matrix resin.

2.1 Preparation of Modified Polyaniline Composites

2.1.1 Preparation Method

The composite material is prepared by one-step chemical in-situ synthesis method, which is simple and easy to implement, as follows:

(1) Take 10g of montmorillonite (MMT) and 125mL H2Press "mix", and then use ultrasonic dispersion for 1 hour to obtain the suspension.

(2) Take 0.1 mol of the hydrophilic group dodecylbenzenesulfonic acid (DBSA) and aniline respectively and add them to 250 mL of H.2Mix evenly in O.

(3) Heat the suspension from (1) in a water bath to 80°C, add the mixture from (2) dropwise at a rate of 2 mL/min, and maintain at constant temperature with stirring for 3 hours, then cool in an ice-salt bath to 2°C.

Add 125 mL of 0.1 mol/L ammonium persulfate dropwise to the solution from step (3) and react for 5 hours.

(5) Centrifuge and wash with ethanol and water until the solution is colorless, then dry at 40°C for 48 hours to obtain a dark green composite material (D-PANI@MMT). Grind to obtain composite material powder.

2.1.2 Experimental Materials

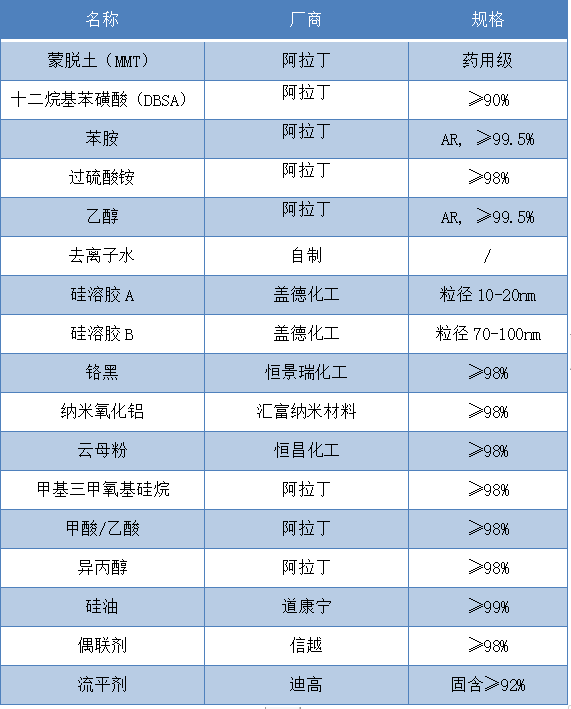

The main materials and specifications required for the experiment are shown in Table 1.

Table 1 Main Experimental Materials

2.1.2 Instruments and Equipment and Their Uses

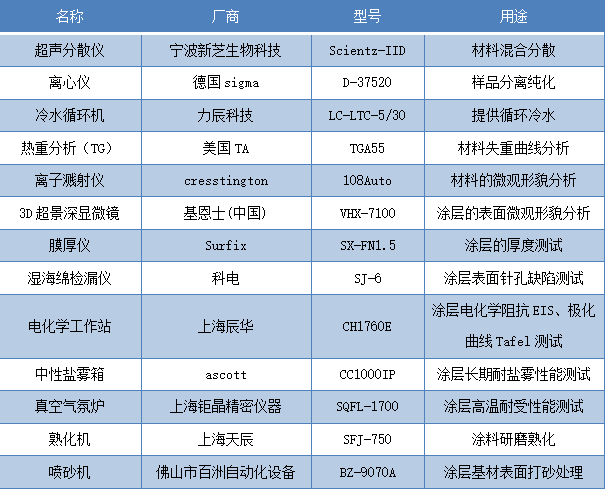

The instruments required for testing in this text and their purposes are shown in Table 2.

Table 2 Main Experimental Instruments and Their Uses

2.2 Preparation of Water-based Ceramic Coating

Select cold-rolled steel plates with an iron content of ≥99.5% as the metal substrate, and use a sandblasting machine for surface grinding treatment. The surface must be uniformly rough and matte after treatment, and set aside for later use.

(1) The preparation process of the primer for high-temperature resistant and anti-corrosion water-based ceramic coating is as follows:

① Mix silica sol A (10 parts), silica sol B (30 parts), chrome black (10 parts), aluminum oxide (10 parts), mica (3 parts) by mass ratio, add 30 parts of glass beads with a diameter of about 3mm, and roll mature on the curing machine for 2 hours.

② Add 20 portions of composite material D-PANI@MMT to ①, and continue rolling and curing for 0.5 hours.

Add 30 parts of methyltrimethoxysilane, 2 parts of coupling agent, and 0.5 parts of acetic acid (mixed at a 1:1 ratio) to ② for hydrolysis reaction for 3 hours.

Add 5 parts isopropanol, 1 part silicone oil, and 1 part leveling agent to mixture ③ and let it cure for 2 hours.

(2) The preparation process of high-temperature resistant and anti-corrosion water-based ceramic coating topcoat is as follows:

Take silica sol A (12 parts) and silica sol B (36 parts) by mass ratio, add 30 parts of glass beads with a diameter of about 3mm, and roll and cure for 2 hours in a curing machine.

② Take 40 parts of methyltrimethoxysilane and 0.4 parts of acetic acid (mixed 1:1), add them into ② for hydrolysis reaction for 3 hours.

Mix 7 parts isopropanol, 2 parts silicone oil, and 1 part leveling agent into③ and allow it to mature for 2 hours.

(3) Fix the sandblasted cold-rolled steel plate, filter the primer and topcoat separately, and load them into two spray guns with a nozzle size of 1-1.5 mm. The primer should be sprayed to a thickness of approximately 30 um and the topcoat to a thickness of approximately 15 um.

(4) The sprayed sample is surface-dried at 120°C for 5 minutes, and then baked at 280°C for 15 minutes to obtain the final high-temperature resistant anti-corrosion water-based coating.

Characterization of Modified Polyaniline Composites

3.1.1 Thermogravimetric Analysis

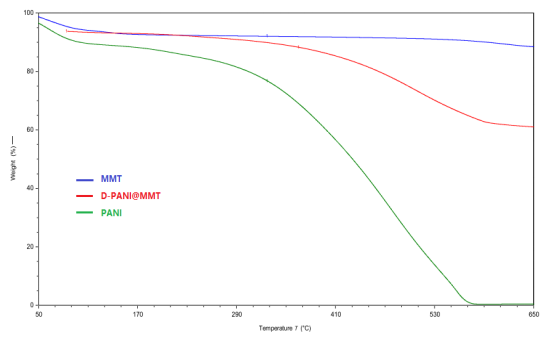

The comprehensive thermal analysis of PANI, MMT, and D-PANI@MMT shows the thermal weight loss changes in Figure 3. It can be seen that PANI experiences around 5% weight loss from room temperature to 200℃, mainly due to the loss of free water and residual aniline molecules from the material surface upon heating. In the phase from 300℃ to 600℃, PANI starts to break its molecular chains at around 285℃, gradually leading to the breakdown of the hydroxyl bond structure framework until complete oxidation, resulting in a weight loss rate of up to 95%. MMT experiences around 5% weight loss from room temperature to 100℃, mainly due to the loss of free water from the material surface. Between 550℃ and 650℃, there is about 8% weight loss, primarily due to the escape of structural water from the interlayers of montmorillonite upon heating. D-PANI@MMT exhibits a weight loss rate of approximately 3.6% from room temperature to 100℃, which is still due to the loss of free water. Between 285℃ and 600℃, the weight loss rate is around 30%, which can be attributed to the continuous decomposition of PANI loaded on MMT until complete decomposition and the small amount of structural water escaping from the montmorillonite interlayers. In summary, the weight loss temperatures and weight percentages on the thermogravimetric curve prove the presence of PANI, and aniline polymerization occurs in the interlayers of MMT.

Figure 3 Sample Thermogravimetric Curve

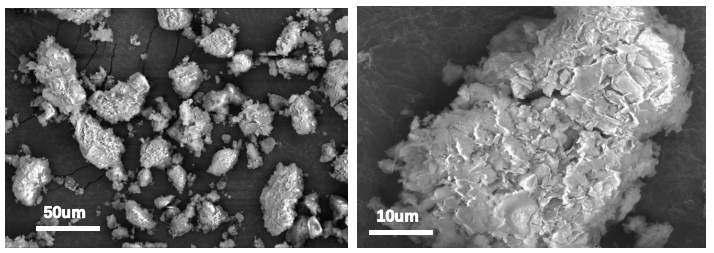

3.1.2 Morphology Analysis

SEM analysis of MMT and D-PANI@MMT was conducted. Figure 4 shows that the particle morphology of MMT is relatively uniform, and upon magnification, the distinct layered structure on its surface can be observed, consistent with the theoretically reported lamellar structure. Figure 5 shows that the particles of in-situ synthesized D-PANI@MMT have significantly enlarged, and there is a noticeable polymer incorporation on the surface and between the layers, indicating that PANI is well-loaded on MMT.

Figure 4 SEM Image of MMT

Figure 5 SEM image of D-PANI@MMT

3.2 Coating Performance Characterization

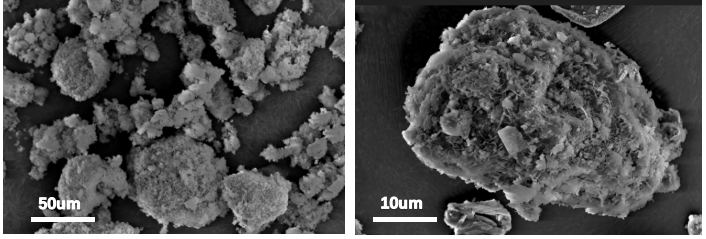

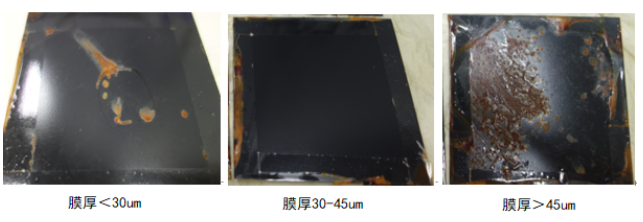

3.2.1 Film Thickness and Pinhole Defect Testing

Using a wet sponge leak detector to conduct microscopic pinhole detection on the coating, the results show that when the coating thickness is less than 30 um, there are obvious pinhole defects. Salt spray tests indicate that rust spots first appear at pinhole locations. When the thickness is ≥30 um, pinhole defects disappear, and there are no obvious rust spots after 10 days of salt spray testing. However, experiments show that when the thickness exceeds 45 um, the coating exhibits cracking after baking and drying, and salt spray tests reveal entire rust spots at the cracking locations. Therefore, it is determined that the optimal spraying thickness of the coating should be between 30-45 um.

Figure 6 Corrosion resistance effect of coatings with different film thicknesses

3.2.3 Normal/High Temperature Corrosion Resistance Testing

Ambient Salt Spray Test: Seal the back side (uncoated side) and the edges of the coated surface of the prepared sample with sealing tape, and place it in a neutral salt spray chamber that meets national standards. Record the rust spots on the coated surface every 24 hours, and conduct continuous testing for 240 hours. If no obvious rust spots appear on the coated surface, it is deemed qualified.

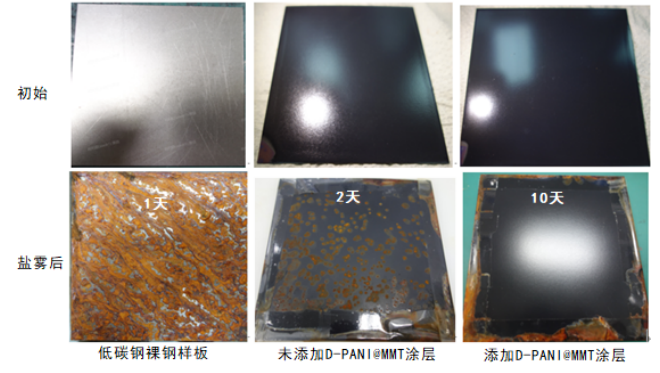

The normal temperature salt spray test indicates (Figure 7) that bare low-carbon steel samples undergo extensive corrosion within 24 hours. Samples without the D-PANI@MMT coating show significant rust spots on the surface after 48 hours, indicating no obvious anti-corrosion performance. Samples with the D-PANI@MMT coating show no rust spots and maintain good surface gloss after 240 hours, demonstrating that the coating with the added D-PANI@MMT anti-corrosion filler has excellent anti-corrosion performance.

Figure 7 Before and After Neutral Salt Spray Test at Room Temperature

High-temperature salt spray test: Place the prepared sample in a muffle furnace set at a constant temperature of 400°C, and after continuous heating for 20 hours, cool it to room temperature. Then, perform the neutral salt spray test at normal temperature by placing the sample in a salt spray chamber. Record the rust spot condition on the coating surface every 24 hours for a continuous test duration of 240 hours. If no significant rust spots appear on the coating surface, it is deemed qualified.

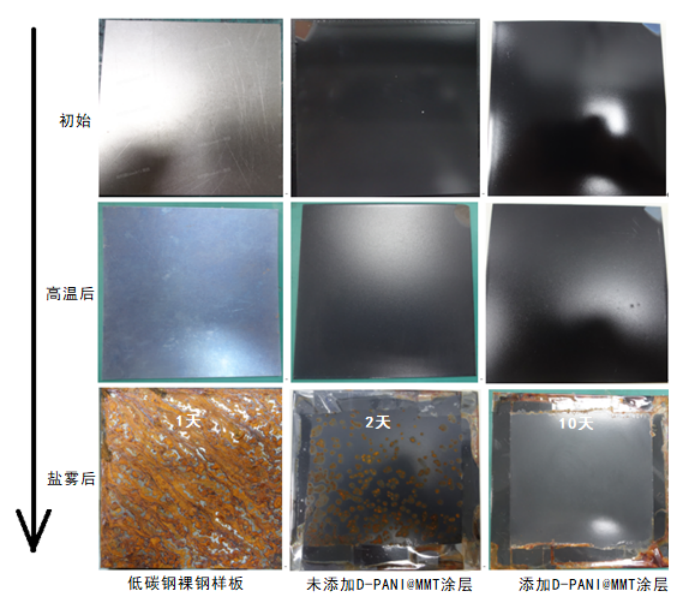

High-temperature salt spray tests indicate (Figure 8) that low-carbon steel bare samples and samples without D-PANI@MMT coating experience extensive corrosion within 24 hours when placed in a salt spray chamber after being continuously heated at 400°C for 20 hours, showing no high-temperature corrosion resistance. In contrast, samples with D-PANI@MMT coating, after being continuously heated at 400°C for 20 hours, exhibit a slight decrease in surface gloss due to the volatilization of silicone oil components in the coating under high-temperature combustion. When placed in a salt spray chamber for 240 hours, the coating surface shows no rust spots, further demonstrating that the coating with added D-PANI@MMT anti-corrosion filler possesses excellent anti-corrosion performance in high-temperature and high-humidity environments.

The modified polyaniline water-based ceramic coating effectively improves the uniform dispersion of polyaniline materials in water-based coatings, while enhancing the mechanical properties and thermal stability of the material. This allows the coating to exhibit good thermal stability and anti-corrosion performance when used at high temperatures.

Figure 8 After High Temperature Neutral Salt Spray Test

3.2.2 Electrochemical Corrosion Performance Test

To simulate a marine corrosion environment, a NaCl solution with a concentration of 5 wt.% (mass fraction) was prepared. Samples with and without the D-PANI@MMT coating were used as working electrodes (test area of 1 cm²), a carbon rod electrode was used as the reference electrode, and a flat corrosion electrochemical cell with a built-in platinum counter electrode was used for electrochemical testing. Bare low-carbon steel was used for comparison. Before each test, open circuit potential (OCP) stability was confirmed, followed by electrochemical impedance spectroscopy (EIS) and polarization curve testing.

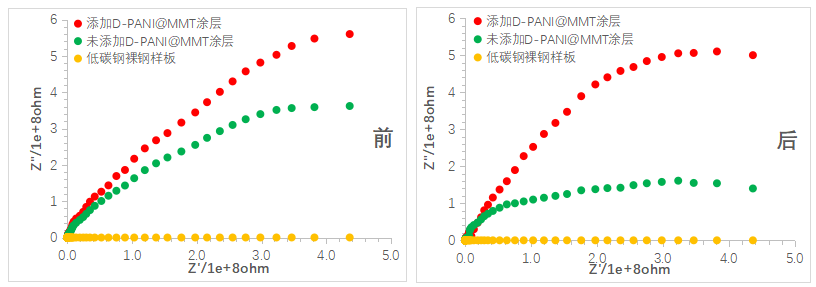

The initial state and the electrochemical impedance spectroscopy (EIS) after soaking in NaCl solution for 10 days were tested for each sample, and the corrosion protection performance of each coating was compared and analyzed. Figure 9 shows the Nyquist plots of each coating before and after soaking. It can be observed that the radius of the capacitive arc of the coating sample with added D-PANI@MMT slightly decreased after 10 days of soaking but still remained within a relatively large range. In contrast, the radius of the capacitive arc of the coating sample without added D-PANI@MMT rapidly decreased after 10 days of soaking, indicating a quick decline in corrosion protection performance. The bare low-carbon steel sample before and after soaking shows that it is prone to corrosion.

Figure 9 Nyquist plots of the coating before and after 10 days of immersion

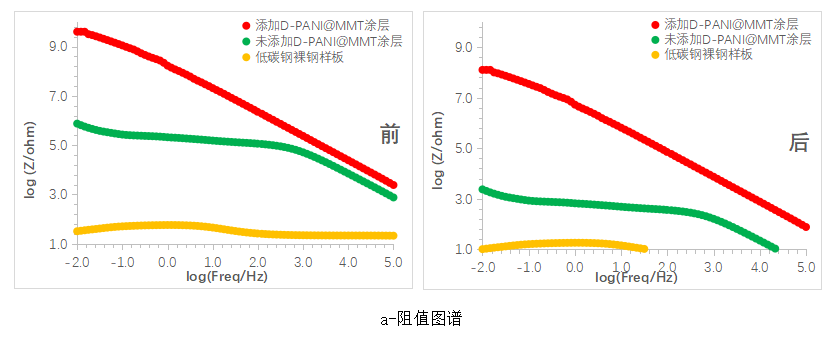

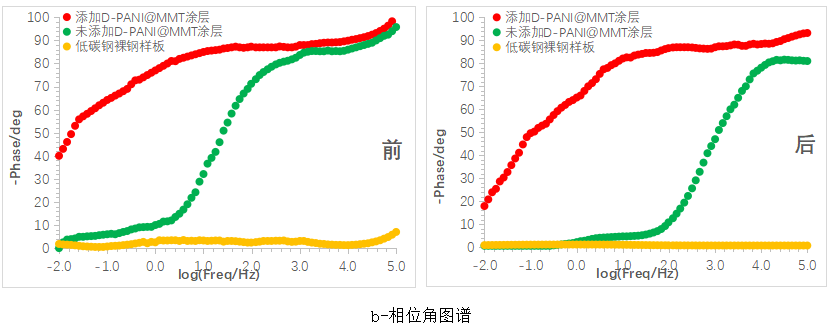

Figure 10 shows the Bode plots of various coatings before and after immersion. In the impedance plot, it can be seen that the sample with the D-PANI@MMT coating shows a decrease in impedance in the mid to low frequency range after 10 days of immersion, but still maintains an order of magnitude above 10^8, indicating excellent corrosion resistance. The sample without the D-PANI@MMT coating exhibits a significant drop in impedance across the entire frequency range after 10 days of immersion, indicating a rapid decline in corrosion resistance.

In the phase angle diagram, it can be observed that with the increase in immersion time, the phase angle of the samples with the D-PANI@MMT coating slightly shifts towards smaller angles overall, more notably in the mid-low frequency region, indicating a decrease in resistive properties and an increase in capacitive properties, which is consistent with the conclusions from the resistance diagram. As for the coating samples without D-PANI@MMT, after 10 days of immersion, the overall phase angle shifts towards smaller angles with a larger magnitude, consistent with the rapid decrease in impedance values.

Figure 10 Bode plots of the coating before and after immersion for 10 days (a- impedance plot, b- phase angle plot)

3.3 Oven Application Research

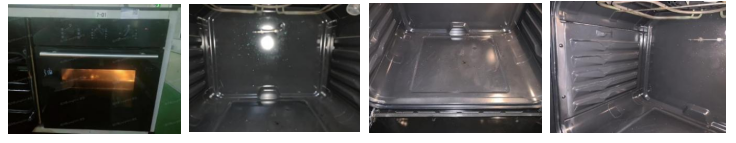

The coating with added D-PANI@MMT was subjected to long-term corrosion resistance testing in an oven for the entire unit. The results showed that after completing 370 cycles of use, there were no rust spots or peeling observed on the coating surface (as shown in Figure 11).

Figure 11 Oven Coating after 370 Cycles of Long Operation

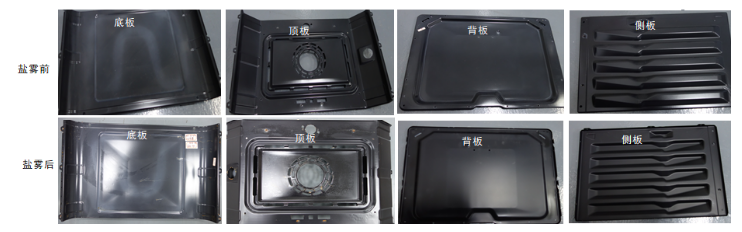

After completing 370 cycles, place the oven cavity panel into the salt spray chamber for corrosion resistance testing. Observe the condition of the coating rust spots after 10 days. Figure 12 indicates that after undergoing salt spray testing, the coating with added D-PANI@MMT did not show significant rust spots, demonstrating excellent anti-corrosion performance in the actual application on the oven.

Figure 12 Long-lasting coating after 10 days of salt spray test

This article describes the aqueous modification of polyaniline (PANI) using dodecylbenzene sulfonic acid (DBSA), and the composite formation with montmorillonite (MMT) as a carrier, effectively improving the dispersion uniformity of polyaniline in aqueous coating systems. The prepared polyaniline composite coating achieved ideal corrosion protection for steel. Through normal and high-temperature salt spray and electrochemical tests, it was shown that the coating maintained salt spray performance >240 hours and impedance value >10^8 even after continuous burning at 400℃ for 20 hours, demonstrating excellent protective effects. After 370 cycles of validation testing on the oven unit followed by 10 days of salt spray testing, the coating surface showed no significant rust spots.

Polyaniline (PANI) itself has excellent anti-corrosion properties, but its hydrophobic and insoluble physical nature limits its large-scale application in industrialization. With the subsequent modification of polyaniline (PANI) and the in-depth research of binary and multi-component composites, it is expected to achieve industrial application.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track