Stop Excessive Wear Caused by Misalignment! Correct Extruder Alignment Practices to Know

Is extruder alignment important? Absolutely! The larger and longer the extruder, the more important it becomes.

Misaligned extrusion can lead to excessive wear of the screw and barrel. The barrel’s attempt to accommodate the bending motion of the screw during each rotation may cause other adverse effects, such as screw breakage, equipment vibration, additional drive load, and, in extreme cases, even "dragging the entire production line."

I personally witnessed the destructive power caused by a misaligned machine. This particular case involved a 4.5-inch extruder with an L/D ratio of 36:1. Here, the barrel was not properly aligned during installation, which caused it to continuously "wobble" during operation. The heater bands crept forward and eventually sheared off some thermocouple holes, and the screw failed after running for only about four months.

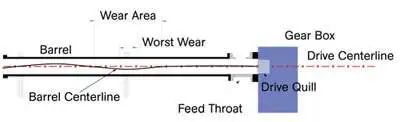

In this case, there is a height difference between the two machine barrels, which should actually be cleaned and aligned using optical instruments for range measurement. The current alignment status is shown in the attached figure.

Due to misalignment and improper design of the two brackets, the screw was bent into an "S" shape. Forcing the rotating screw to align with the bent barrel will result in enormous pressure between the screw threads and the barrel.

In this situation, the screw thread wear exceeds 0.055 inches, and the barrel wear also exceeds 0.015 inches. In the area of "most severe wear" before the screw breaks, even if the strength of the threaded element is ignored, a radial force of more than 155,000 pounds is required to bend the screw beyond this figure. Meanwhile, the pressure from the drive components merely forces the screw into the barrel, resulting in adhesive wear that continuously tears the metal alloys from both surfaces. Ultimately, this continuous and increasing bending exceeds the fatigue strength of the screw, leading to screw fracture.

Correct practice

It should be noted thatThe barrel must be aligned with the driving mechanism, i.e., the drive shaft of the gearbox.Horizontal alignment is completely useless because it does not indicate the drive sleeve and only measures the vertical plane.

The correct procedure is to place the optical or laser alignment mirror inside the drive sleeve and align it with the fixed centerline by rotating the drive sleeve. Then, by adjusting the barrel's bracket or feed port mounting surface, align the barrel and feed port with the centerline.

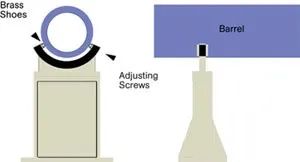

A properly designed barrel is necessary for forming and maintaining good alignment. I prefer a two-point system, as shown in the figure, but there are many other good designs as well.

Taking a single-screw extruder as an example

An important point is that the barrel must be able to expand freely through the supports when heated, without becoming deformed. The barrel should not be locked in place by supports that completely surround it, so that it does not slide easily when expanding. The support points need to be made of non-corrosive materials, such as brass, to prevent corrosion from “freezing” the supports.

It is equally important that the entire barrel stand must be sturdy enough to maintain its position and not topple over as the barrel expands. I believe this is a major weakness in many extruder designs.

If the steel cannot expand linearly, it will bend when heated to a uniform working temperature of 450°F. A 4.5-inch, 36:1 barrel will expand 0.320 inches from room temperature to the working temperature. To check if your bracket is functioning correctly,Please pay attention to the new wear marks when the barrel slides over the bracket. If they do not exactly correspond to the calculated extension, it indicates there is a problem with your bracket alignment system.

4. Since heat waves cause light to bend, barrel alignment must be performed when cooled, whether for optical alignment or laser alignment. When the barrel is heated, it does not necessarily maintain the same position as when cooled, so some additional checks should be carried out after the initial heating to ensure the alignment is flawless.

This can be done by placing a dial gauge at a 90° angle on the discharge flange to check whether there is significant deflection of the barrel when heat is applied. Some factors that may cause this deflection include:Malfunctioning brackets, heating imbalance caused by half of the heater being burned out, half of the heater surrounding the vent, or weak barrel structure.

The larger and longer the extruder, the more important alignment becomes. For larger or longer extruders, there is rarely a base with sufficient rigidity to maintain the manufacturer's alignment.

There are quite a number of skilled extruder calibration technicians who can use appropriate equipment and techniques, but some provide incomplete or even incorrect services. It is best to inquire carefully with them before proceeding.

If you encounter screw breakage, excessive wear of the screw/barrel, barrel swing, or heater creep,In the long run, starting with a properly aligned extruder can save you a lot of money and downtime.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track