Sinopec launches cyclo-olefin copolymer (coc) project! global

Recently, the fixed asset investment project for the cyclic olefin copolymer (COC) unit of Sinopec (Tianjin) Petrochemical Co., Ltd. has been registered.

Project Name:Sinopec (Tianjin) Petrochemical Co., Ltd. Cycloolefin Copolymer (COC) Plant Project

Declaration Serial Number:202509120254

Item Name:Domestic Fixed Asset Investment Project Filing - New Application

Implementing Entity:Administrative Approval Bureau of the Economic Development Zone

Filing Date:2025-09-12

Sinopec (Tianjin) Petrochemical Co., Ltd.'s cyclic olefin copolymer (COC) project is an important development in its high-end polymer sector.

Project Basic Information: The company's cycloolefin copolymer project is located within the olefin department, and the construction content includes850 tons/year norbornene unit and 1000 tons/year cycloolefin copolymer unitThe above-mentioned content translates to: "As well as supporting facilities such as loading and unloading stations, packaging warehouses, power distribution and transformation, and equipment rooms, with an annual operating time of 8,000 hours, the COC production capacity is 1,000 tons/year."

Sinopec Group's obtained patents related to cycloolefin copolymers include:

A method for the continuous aggregation preparation of cycloolefin copolymers.Applied by China Petroleum & Chemical Corporation and Sinopec Shanghai Petrochemical Company Limited, the publication number is CN120383694A, and the application date is January 2024. This patent directly obtains a toluene solution of norbornene through distillation. The solution is in liquid form, making it easier to transport through pipelines, and allows for the subsequent copolymerization with ethylene, achieving continuous preparation of cyclic olefin copolymers, which is more economical.

Ethylene-norbornene copolymer and its preparation method.The patent application, submitted by China Petroleum & Chemical Corporation and Sinopec (Beijing) Chemical Research Institute Co., Ltd., has the application number CN202111158844.5 and was authorized on May 7, 2024. The preparation method for the ethylene-cycloolefin copolymer includes using a catalyst composition to carry out the copolymerization reaction of ethylene and cycloolefin, where the catalyst composition comprises metallocene compounds, co-catalyst components, and phenols. This method can increase the molecular weight of the polymer and enhance the content of cycloolefin in the copolymer, thereby improving the glass transition temperature of the polymer.

System for preparing polar ethylene-cycloolefin copolymers and their applications, polar ethylene-cycloolefin copolymers and their polymerization methods.The patent, applied by China Petroleum & Chemical Corporation and Sinopec (Beijing) Research Institute of Chemical Industry Co., Ltd., with the application number CN202210345346.X and publication number CN116925275A, involves a system for preparing polar ethylene-norbornene copolymers and its applications, polar ethylene-norbornene copolymers, and their polymerization methods. The system includes at least one metallocene compound, at least one aluminoxane, at least one organoaluminum compound AlR'mX3-m, ethylene, and a monomer represented by formula I. When the system is used for polar ethylene copolymers, it not only has high activity but also can produce polar ethylene-norbornene copolymers with high molecular weight and high comonomer content.

Ethylene-norbornene copolymer and its preparation method.The patent applied for by China Petroleum & Chemical Corporation and Sinopec (Beijing) Chemical Research Institute Co., Ltd., with application number CN202310715944.6 and publication number CN119143911A, was filed on June 2023. The preparation method of ethylene-cycloolefin copolymer involves using a catalyst composition to carry out a copolymerization reaction between ethylene and cycloolefin, where the catalyst composition includes a transition metal compound of the structure shown in formula (1) and a co-catalyst component. This method has the advantage of improving copolymerization activity.

Cyclic olefin copolymers (COC) are a type of chemical resin material that have emerged in recent years. Due to their high transparency, good dimensional stability, low moisture absorption, and chemical resistance, they are widely used in optics, medical, and electronics fields, showing great development potential.

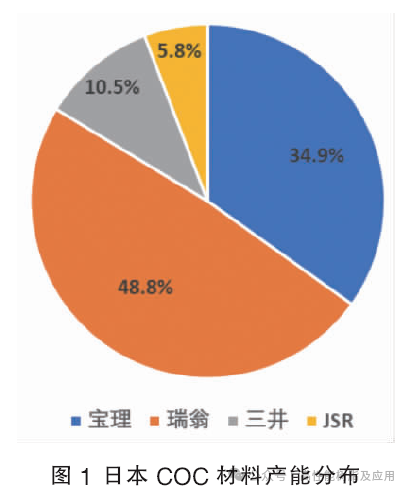

In the global COC market, Japanese companies hold a dominant position due to their extensive technical expertise and strong research and development capabilities. Key manufacturers include Zeon Corporation, Polyplastics, Mitsui Chemicals, and Japan Synthetic Rubber (JSR), with a total production capacity of approximately 86,000 tons per year, as shown in the chart. Zeon Corporation and Polyplastics, leveraging their technological advantages in the optical and medical fields, occupy a significant market share. Mitsui Chemicals demonstrates strong competitiveness in the optical and automotive lens sectors, meeting the demand for high-performance COC materials through continuous technological innovation and product upgrades. This differentiated competition strategy allows Japanese companies to maintain a leading position in the COC market, while also driving the sustained development of the global COC industry.

In recent years, the global COC (Cyclic Olefin Copolymer) industry has experienced rapid development, with expanding application fields and increasing demand, leading to industrial-scale mass production. However, there are still some issues in the course of development, such as technical challenges in the production process, high production costs, uncoordinated inter-industry development, and potential threats from international competition, which constrain the further development of the COC industry. In the future, efforts need to be made in several areas, including enhancing policy support, strengthening technological innovation, reinforcing industry chain collaboration, and expanding application markets, to promote the green development of the global COC industry.

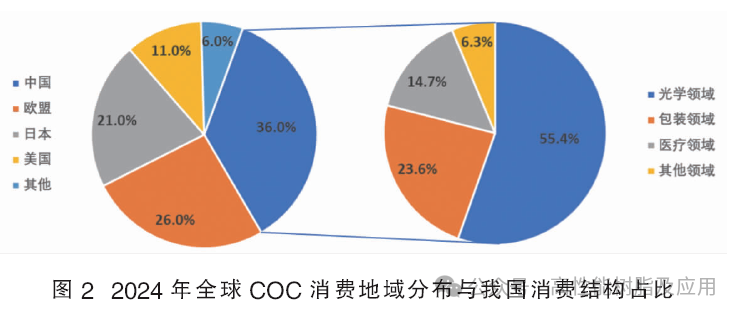

In 2024, the global consumption of COC is approximately 90,000 tons, with China being the largest consumer, accounting for 36% of global consumption. The consumption structure of COC in China is as follows: the optical field accounts for 55.4%, packaging and medical fields account for 23.6% and 14.7%, respectively. This consumption structure reflects the high dependence on COC materials in the optical field. As downstream industries such as consumer electronics and new energy vehicles shift towards domestic markets, the demand in the optical field will continue to grow.

By the end of 2025, the global consumption of COC is expected to grow to 118,500 tons, an increase of 24% year-on-year. In particular, the rapid development of emerging application fields such as mobile phone lenses, vehicle-mounted lenses, and AR/VR devices provides a broad market space for COC materials.

In the process of the global COC (cyclic olefin copolymer) industry development, there are a series of technical barriers that restrict the development and application of COC materials. Firstly, the preparation of cyclic olefin monomers is a key challenge. Currently, this technology is mastered only by a few Japanese companies, and other countries face varying degrees of technical barriers. Furthermore, the screening and development of metallocene catalysts is another core technical challenge that restricts the development of the COC industry. Metallocene catalysts are an indispensable part of COC production, with properties such as solubility, high activity, and homogeneous catalytic effects. They can adjust the polymer molecular weight and design the polymer microstructure by altering polymerization temperature, catalyst concentration, or ligands. However, the preparation of metallocene catalysts is extremely challenging and is referred to as the "crown jewel" of the catalyst industry. Their complete system includes the main catalyst, co-catalyst, and carrier, which need to be selected according to the reaction. For a long time, companies have been blocking this technology. The above factors further increase the difficulty of technical breakthroughs. Therefore, enhancing independent innovation capabilities, overcoming technical bottlenecks, and achieving independent and controllable technology are the primary tasks for developing the COC industry.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track