Sinochem International Showcases Multiple Innovative Achievements at the 2025 China International Composites Exhibition

September 16

Sinochem International by"Fine Chemicals, Green Life"For the theme

Featuring multiple innovative achievements.

2025 China International Composites Industry Technology Exhibition

As an industry-leading supplier of composite material solutions, Sinochem International offers a range of products in the field of composite materials, including epoxy resins and high-performance materials. The company focuses on showcasing its comprehensive solutions in various sectors such as new energy vehicle power batteries, transportation, sports and leisure, clean energy, and the low-altitude economy.

Sinochem International adheres to the concept of innovation-driven and sustainable development, continuously focusing on the pain points of industry development needs, concentrating on developing comprehensive integrated material solutions, and leading new development trends in the industry.

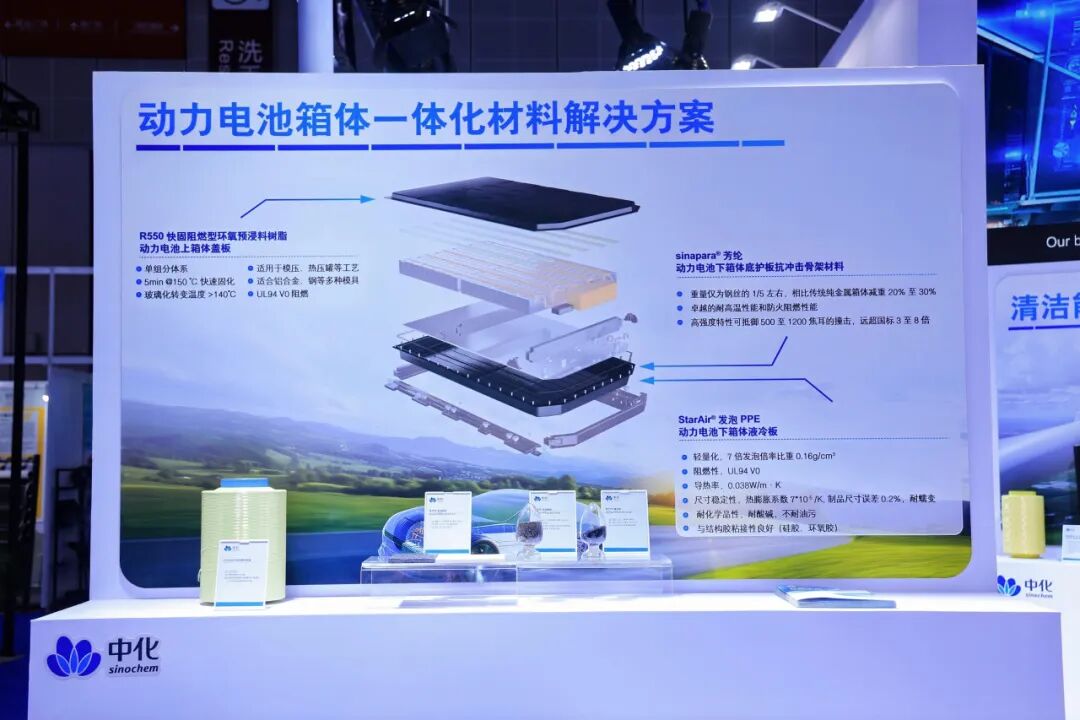

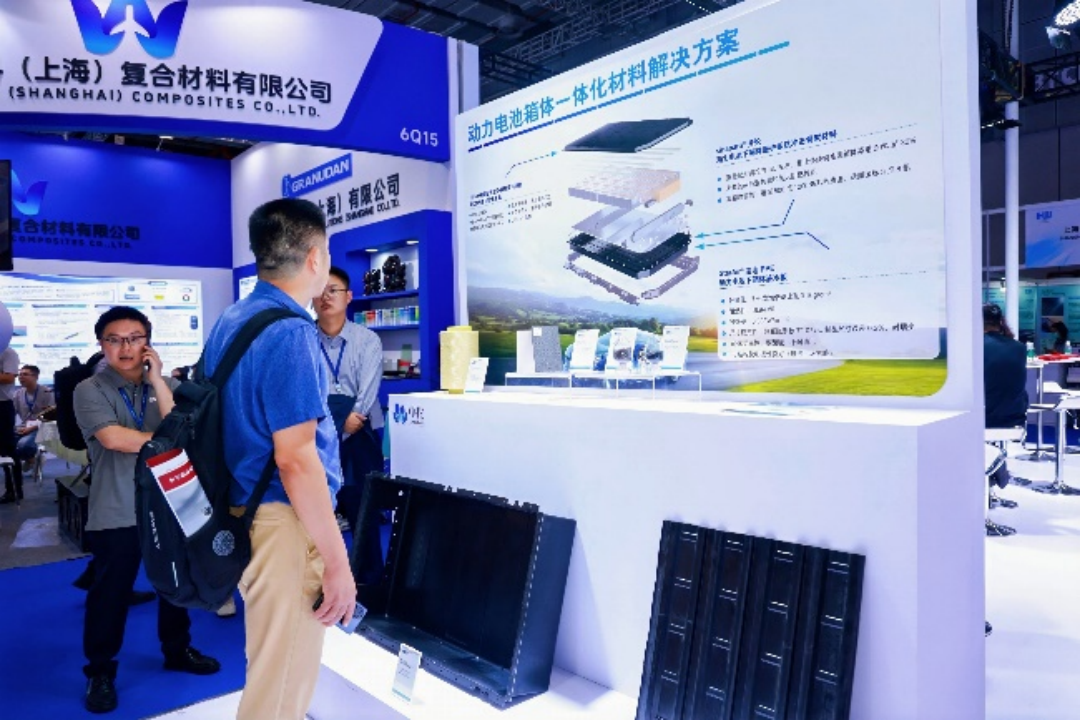

Integrated Material Solutions for Power Battery Boxes

In response to the safety upgrade requirements of the new national standards for power batteries, Sinochem International showcased its flame-retardant series of epoxy prepreg resin, Sinapara, for the first time at this exhibition.®Aramid NCF warp-knitted fabric and StarAir®The integrated material solution for power battery boxes composed of three core materials of foamed PPE can meet the performance requirements of power battery systems for "high safety, lightweight, and long range."

● Flame-retardant series epoxy prepreg resin: applied to the upper box cover plate of the power battery pack.

The core advantages of the flame-retardant series epoxy prepreg resin lie in its combination of flame retardancy, lightweight, and high strength, easily meeting the most stringent battery pack fire safety standards (such as UL94 V0), addressing the core safety issues of traditional materials being flammable and lacking fire resistance. The prepreg compression molding technology enables the integration of complex structures, significantly reducing weight and enhancing vehicle range. Its high specific strength and modulus ensure excellent impact, vibration, and extrusion resistance for the casing. Its superior thermal stability, electrolyte corrosion resistance, and reliable sealing performance provide a comprehensive, high-safety protective barrier for power batteries.

● sinapara®Aramid NCF warp-knitted fabric: Applied to the bottom protective plate of the power battery pack lower case.

Thanks to Sinapara of Sinochem International®The ultra-high strength characteristics of aramid can help the battery box withstand bottom impacts of 500 to 1200 joules, which is 3 to 8 times higher than the national standard. This ensures that the box will not be penetrated or deformed.®Aramid's excellent high-temperature resistance and fire-retardant properties can prevent the spread of fire in case of an internal cell catching fire, reducing the possibility of the entire battery pack burning or even exploding.®Aramid also has lightweight characteristics, with its weight being only about 1/5 that of steel wire. It successfully helps the battery box product reduce weight by 20% to 30% compared to traditional pure metal boxes, effectively optimizing the energy consumption performance of the entire vehicle.

● StarAir®Foamed PPE: Applied to the liquid cooling plate of the lower housing of power battery packs

Through the comparison of dozens of different material schemes, the "sandwich" composite core material, utilizing a combination of composite materials and foamed PPE technology, can achieve high temperature resistance, high rigidity, and flexibility in complex structures. This contributes to a 14% weight reduction and effectively enhances endurance, offering more advantages compared to traditional composite core materials.

Lightweight Bicycle Material Solutions

At this exhibition, Sinochem International showcased for the first time the application of high-toughness epoxy prepreg resin in lightweight bicycles, such as high-end carbon fiber road bikes and mountain bikes.

The prepreg resin significantly improves the impact resistance and fatigue performance of carbon fiber components with its exceptional toughness, effectively resisting cracking and delamination. It transforms the previous brittle fracture into a more resilient energy absorption mode, addressing the reliability issues of traditional epoxy carbon fiber frames that are prone to sharp impacts and have weak impact resistance. This achieves a balance of "lightweight," "high rigidity," and "high toughness," effectively solving the key pain points of traditional carbon fiber composite materials and providing riders with enhanced safety and riding experience.

At this exhibition, Sinochem International focused on promoting a series of epoxy resins and high-performance material products in the fields of transportation, clean energy, and low-altitude economy composite applications. The company showcased the environmental friendliness and green sustainability of its products, highlighting the future development direction of their application. It demonstrated its determination and confidence in driving industry upgrades in terms of products and processes.

DCPD-RIM series resin solutions for construction vehicles

The poly(dicyclopentadiene) (PDCPD) resin independently developed by Sinochem International is a high-performance engineering plastic. Its application in the exterior parts of engineering machinery effectively solves multiple application challenges of traditional materials.

PDCPD material possesses exceptionally high impact strength and toughness, effectively resisting stone impacts and minor collisions in harsh working conditions of construction machinery, addressing the durability issue of components that are prone to cracking and damage. Additionally, its reaction molding process is almost unrestricted by product size and shape, allowing for the integrated molding of large, complex surface appearance parts with exquisite textures, avoiding the seam issues of metal materials. Moreover, the excellent corrosion resistance of PDCPD material itself enables it to withstand the erosion of oil stains, chemicals, and humid environments, solving potential leakage problems inherent in traditional materials. From a production standpoint, its low-pressure reaction injection molding (RIM) cycle is extremely short, significantly enhancing production efficiency and cost-effectiveness, addressing the pain points of long production cycles and high costs for large non-metallic parts.

High-performance epoxy resin hydrogen storage cylinder composite material solution

Sinochem International actively responds to the demands of the new energy market by developing a low-viscosity, long-pot-life, tough, and heat-resistant epoxy resin formulation 9824A/B for Phoenix fiber winding, addressing the material technical requirements for hydrogen fuel cell vehicle storage tanks. This product is suitable for Type III and Type IV hydrogen storage tanks. It features low viscosity and good wettability with carbon fiber and glass fiber, easily penetrating fiber gaps to reduce the difficulty of process molding. The low viscosity also facilitates the expulsion of air bubbles from the resin, preventing the formation of surface bubbles or internal voids in the composite material post-curing, which could result in product defects.

Epoxy Resin Vacuum Infusion System Solution

As a global leading supplier of epoxy resin, Sinochem International has been deeply engaged in the clean energy industry. It has independently developed the "high-purity epoxy resin purification and separation process" and the "segmented reaction and closed-loop process for epoxy resin." Through process integration, it can meet the needs of wind turbine blade manufacturers for resins with different properties.

The epoxy resin vacuum infusion system solution exhibited this time consists of a two-component system of epoxy resin YN8138A and curing agent YN8138B. It features moderate viscosity, long operating cycle, and low exotherm. The fully cured resin system has high mechanical strength, excellent heat resistance, and superior fiber impregnation and adhesion properties. This system fully meets all the performance requirements of DNV-GL (Det Norske Veritas - Germanischer Lloyd) for infusion systems used in wind power.

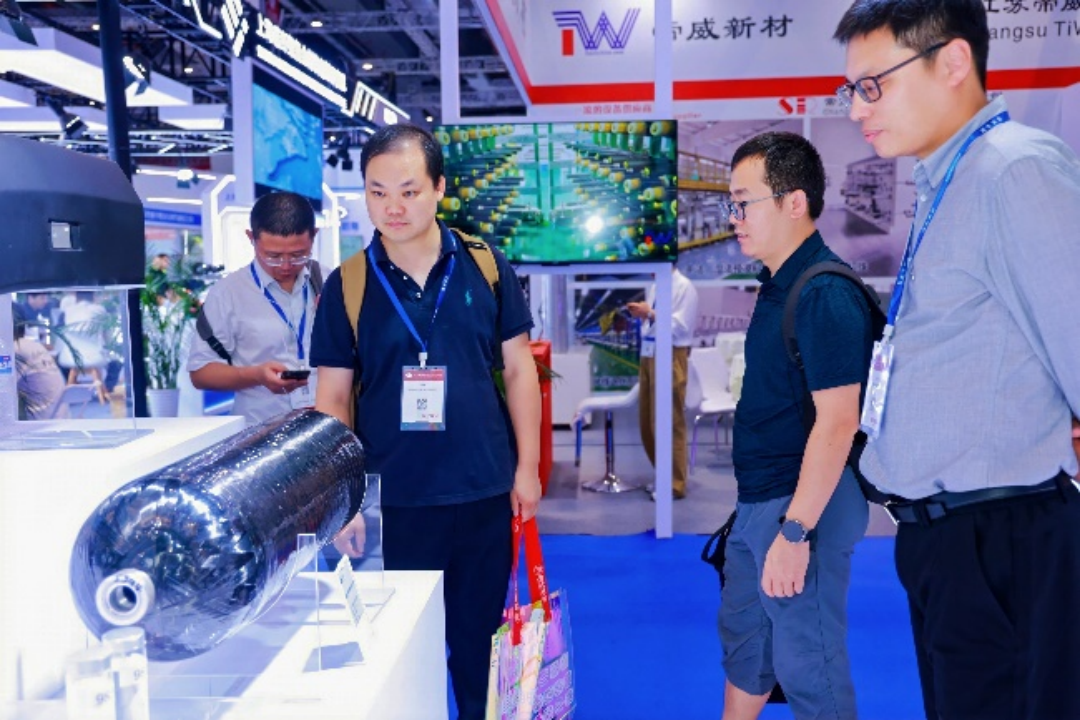

During the exhibition, Sinochem International's booth attracted numerous domestic and international customers and buyers to discuss business and explore industry development trends. Technical personnel provided detailed explanations to customers and visitors about the main features, advantages, and applications of various showcased products and solutions, actively understanding customer needs to better meet market demands.

During the technical exchange session, Sinochem International shared a thematic presentation titled "Application of Para-aramid in Composites," providing a systematic introduction to sinapara.®Para-aramid, as a key reinforcement in high-end composite materials, offers performance advantages such as high strength, high modulus, impact resistance, and lightweight characteristics. Natural para-aramid fibers can provide core protection and lightweight load-bearing for high-pressure vessels and civil aviation structural components. The colored fibers, achieved through solution-dyeing technology, have stable color and can be directly applied to end products such as sports equipment and consumer electronics casings. They combine aesthetic value with the advantage of no need for painting, expanding the possibilities of composites in consumer fields, and have garnered significant attention and recognition from professional audiences on-site.

More excitement, inviting you to enjoy together.

Welcome to the Sinochem International booth (6.1Q18) during the 2025 China International Composites Expo. We look forward to face-to-face exchanges with you to explore new opportunities in the future development of composite materials. We anticipate your presence!

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track