Sino Prosperity: The first 60CM wide PPS film production line in China has completed debugging

On February 26, the Sichuan Economic Daily specially reported on Meishan High-tech Zone's achievement of being one of only two in the country and the sole in Sichuan to be a dual benchmark for "technological innovation" and "green development," with Zhongke Xingye's newly developed capsaicin production line and the first 60CM wide PPS film production line in China becoming the focus of R&D innovation in the industry.

On February 26, the Sichuan Economic Daily specially reported on Meishan High-tech Zone's achievement of being one of only two in the country and the sole in Sichuan to be a dual benchmark for "technological innovation" and "green development," with Zhongke Xingye's newly developed capsaicin production line and the first 60CM wide PPS film production line in China becoming the focus of R&D innovation in the industry.

On February 26, the Sichuan Economic Daily specially reported on Meishan High-tech Zone's achievement of being one of only two in the country and the sole in Sichuan to be a dual benchmark for "technological innovation" and "green development," with Zhongke Xingye's newly developed capsaicin production line and the first 60CM wide PPS film production line in China first 60CM wide PPS film production line in China becoming the focus of R&D innovation in the industry.

The successful commissioning of the company's latest 60CM wide "polyphenylene sulfide" film production line marks a new step for China in the field of high-performance film material manufacturing. Polyphenylene sulfide films, with their excellent mechanical properties, chemical resistance, and electrical insulation, are widely used in electronic components, new energy batteries, environmental protection filtration, and other fields. The launch of this production line will greatly enhance the domestic self-sufficiency capability in high-end film materials, breaking the foreign technological monopoly.

Sichuan Zhongke Xingye High-tech Materials Co., Ltd., established in July 2013, is a national high-tech enterprise focusing on the transformation of high-tech achievements. The company uses the research and development of polyarylene sulfide (PAS) class (PASS, PASK, PPSA, PPS, etc.) polymer materials as its technological breakthrough point, specializing in the "research, production, and sales" of national cutting-edge polymer composite materials such as polyarylene sulfide sulfone (PASS) and polyphenylene sulfide (PPS), along with their deep processing separation membranes.

The company's products and business scope include: special engineering materials of the polyarylene sulfide class, modified special engineering materials, automotive structural component products and special engineering plastic dedicated materials, lithium battery new energy products and special engineering plastic dedicated materials, hydrogen battery products and special engineering plastic dedicated materials, military and aerospace composite materials, continuous fiber thermoplastic composites, and more. Products have entered multiple market areas and are widely applied in military-grade engines, aerospace, lithium battery new energy/hydrogen, and electronic appliances.

Zhongke Xingye has developed a complete process technology and equipment solution for PPS short fiber preparation. The prepared high-strength hydrophilic PPS short fibers, after spinning and weaving, possess good thermal stability, chemical stability, flame retardancy, and electrical insulation, with high porosity, large specific surface area, easy functional modification, and good controllability of structure. PPS short fibers can be made to meet the actual usage requirements in terms of various performance indicators.

The company has recently completed the commissioning of a 60CM wide "polyphenylene sulfide" film production line, marking a new milestone in the domestic manufacturing of high-performance film materials. Polyphenylene sulfide films, with their excellent mechanical properties, chemical resistance, and electrical insulation, are widely used in electronic components, new energy batteries, and environmental filtration fields. The launch of this production line will greatly enhance the domestic self-sufficiency in high-end film materials and break the foreign technological monopoly.

Sichuan Zhongke Xingye High-Tech Materials Co., Ltd., established in July 2013, is a national high-tech enterprise that focuses on the transformation of high-tech achievements, using the research and development of polyarylene sulfide (PAS) (PASS, PASK, PPSA, PPS, etc.) polymer materials as its technical breakthrough point. The company specializes in the "research, production, and sales" of state-of-the-art polymer composite materials such as polyarylene ether sulfone (PASS) and polyphenylene sulfide (PPS), along with their deep-processed separation membranes.

The company's products and business scope include: special engineering materials of polyarylene sulfide, modified special engineering materials, automotive structural parts and special engineering plastic materials, lithium battery new energy products and special engineering plastic materials, hydrogen fuel cell products and special engineering plastic materials, military and aerospace composite materials, and continuous fiber thermoplastic composites. The products have entered various market sectors and are widely applied in military engines, aerospace, lithium battery new energy/hydrogen energy, and electronic and electrical fields.

Zhongke Xingye has developed a complete process technology and equipment solution for the preparation of PPS short fibers. The high-strength hydrophilic PPS short fibers produced can be spun into fabrics, exhibiting good thermal stability, chemical stability, flame retardancy, and electrical insulation, with high porosity, large specific surface area, easy functional modification, and good structural controllability. The PPS short fibers can be made into PPS fiber membrane samples that meet the performance requirements for practical use.

The company's recently completed 60CM wide "polyphenylene sulfide" film production line commissioning marks a new level in the domestic manufacturing of high-performance film materials. Polyphenylene sulfide film, with its excellent mechanical properties, chemical resistance, and electrical insulation, is widely used in electronic components, new energy batteries, environmental filtration, and other fields. The launch of this production line will greatly enhance the domestic self-sufficiency in high-end film materials, breaking the foreign technological monopoly.

Sichuan Zhongke Xingye High-tech Materials Co., Ltd., established in July 2013, is a national high-tech enterprise focusing on the transformation of high-tech achievements. It takes the research and development of polyarylene sulfide (PAS) class (PASS, PASK, PPSA, PPS, etc.) polymer materials as its technical breakthrough point, specializing in the research, production, and sales of national cutting-edge high molecular polymer materials such as polyarylene sulfide sulfone (PASS) and polyphenylene sulfide (PPS), as well as their deep-processed separation membranes.

The company's products and business scope include: special engineering materials of the polyarylene sulfide class, modified special engineering materials, automotive structural parts and special engineering plastics dedicated materials, lithium battery new energy products and special engineering plastics dedicated materials, hydrogen fuel cell products and special engineering plastics dedicated materials, military and aerospace composite materials, continuous fiber thermoplastic composites, and more. The products have gradually entered multiple market areas and are widely applied in military-grade engines, aerospace, lithium battery new energy/hydrogen, and electronics and electrical appliances.

Zhongke Xingye has developed a complete process technology and equipment solution for PPS short fiber preparation. The high-strength hydrophilic PPS short fibers produced can be spun into fabrics, exhibiting good thermal stability, chemical stability, flame retardancy, and electrical insulation, with high porosity, large specific surface area, easy functional modification, and good structural controllability. PPS short fibers can be prepared to meet the actual usage requirements for various performance indicators of PPS fiber membrane samples.

The company has recently completed the commissioning of a 60CM wide "polyphenylene sulfide" film production line, marking a new step in the domestic manufacturing of high-performance film materials. Polyphenylene sulfide films, with their excellent mechanical properties, chemical resistance, and electrical insulation, are widely used in electronic components, new energy batteries, environmental filtration, and other fields. The launch of this production line will greatly enhance the domestic self-sufficiency in high-end film materials and break the foreign technological monopoly.

The company has recently completed the commissioning of a 60CM wide "polyphenylene sulfide" film production line, marking a new step in the domestic manufacturing of high-performance film materials. Polyphenylene sulfide films, with their excellent mechanical properties, chemical resistance, and electrical insulation, are widely used in electronic components, new energy batteries, environmental filtration, and other fields. The launch of this production line will greatly enhance the domestic self-sufficiency in high-end film materials and break the foreign technological monopoly.

The company has recently completed the commissioning of a 60CM wide "polyphenylene sulfide" film production line, marking a new step in the domestic manufacturing of high-performance film materials. Polyphenylene sulfide films, with their excellent mechanical properties, chemical resistance, and electrical insulation, are widely used in electronic components, new energy batteries, environmental filtration, and other fields. The launch of this production line will greatly enhance the domestic self-sufficiency in high-end film materials and break the foreign technological monopoly.The launch of this production line will greatly enhance the domestic self-sufficiency in high-end film materials and break the foreign technological monopoly.

Sichuan Zhongke Xingye High-tech Materials Co., Ltd., established in July 2013, is a national high-tech enterprise that primarily focuses on the commercialization of advanced technology. It uses the research and development of polyarylene sulfide (PAS) (such as PASS, PASK, PPSA, PPS, etc.) high molecular materials as its technological breakthrough point. The company specializes in the "research, production, and sales" of national top-tier high molecular polymer materials such as polyarylene ether sulfone (PASS) and polyphenylene sulfide (PPS), along with their deep processing separation membranes.

The company's products and business scope include: special engineering materials of the polyarylene sulfide series, modified special engineering materials, automotive structural parts, and special engineering plastics for dedicated use, lithium battery new energy products and special engineering plastics for dedicated use, hydrogen fuel cell products and special engineering plastics for dedicated use, military and aerospace composite materials, and continuous fiber thermoplastic composites. The products have entered multiple market sectors and are widely used in military-grade engines, aerospace, lithium batteries/new energy/hydrogen, and electronic appliances.

Zhongke Xingye has developed a complete process technology and equipment solution for the preparation of PPS short fibers. The prepared high-strength hydrophilic PPS short fibers, after spinning and weaving, exhibit excellent thermal stability, chemical stability, flame retardancy, and electrical insulation, with high porosity, large specific surface area, easy functional modification, and good controllability of structure. The PPS short fibers can be used to prepare PPS fiber membrane samples that meet the actual performance requirements.

Sichuan Zhongke Xingye High-tech Materials Co., Ltd., established in July 2013, is a national high-tech enterprise that focuses on the transformation of high-tech achievements. It takes the research and development of polyarylene sulfide (PAS) class (PASS, PASK, PPSA, PPS, etc.) polymer materials as its technological breakthrough point. The company is dedicated to the "research, production, and sales" of advanced national polymer composite materials such as polyarylene sulfide sulfone (PASS) and polyphenylene sulfide (PPS), along with their deep-processed separation membranes.

Sichuan Zhongke Xingye High-tech Materials Co., Ltd., established in July 2013, is a national high-tech enterprise that focuses on the transformation of high-tech achievements. It takes the research and development of polyarylene sulfide (PAS) class (PASS, PASK, PPSA, PPS, etc.) polymer materials as its technological breakthrough point. The company is dedicated to the "research, production, and sales" of advanced national polymer composite materials such as polyarylene sulfide sulfone (PASS) and polyphenylene sulfide (PPS), along with their deep-processed separation membranes.

Sichuan Zhongke Xingye High-tech Materials Co., Ltd.Sichuan Zhongke Xingye High-tech Materials Co., Ltd., established in July 2013, is a national high-tech enterprise that focuses on the transformation of high-tech achievements. It takes the research and development of polyarylene sulfide (PAS) class (PASS, PASK, PPSA, PPS, etc.) polymer materials as its technological breakthrough point. The company is dedicated to the "research, production, and sales" of advanced national polymer composite materials such as polyarylene sulfide sulfone (PASS) and polyphenylene sulfide (PPS), along with their deep-processed separation membranes.The company's products and business scope include: special engineering materials of polyarylene sulfide, modified special engineering materials, automotive structural components and special engineering plastic materials, lithium battery new energy products and special engineering plastic materials, hydrogen battery products and special engineering plastic materials, military and aerospace composite materials, continuous fiber thermoplastic composites, and more. The products have entered various market sectors and are widely used in military-grade engines, aerospace, lithium battery new energy/hydrogen, and electronic and electrical fields.

The company's products and business scope include: special engineering materials of polyarylene sulfide, modified special engineering materials, automotive structural components and special engineering plastic materials, lithium battery new energy products and special engineering plastic materials, hydrogen battery products and special engineering plastic materials, military and aerospace composite materials, continuous fiber thermoplastic composites, and more. The products have entered various market sectors and are widely used in military-grade engines, aerospace, lithium battery new energy/hydrogen, and electronic and electrical fields.

The company's products and business scope include: special engineering materials of polyarylene sulfide, modified special engineering materials, automotive structural components and special engineering plastic materials, lithium battery new energy products and special engineering plastic materials, hydrogen battery products and special engineering plastic materials, military and aerospace composite materials, continuous fiber thermoplastic composites, and more. The products have entered various market sectors and are widely used in military-grade engines, aerospace, lithium battery new energy/hydrogen, and electronic and electrical fields.Zhongke Xingye has developed a comprehensive process technology and equipment solution for PPS short fiber preparation. The high-strength hydrophilic PPS short fibers produced, after being spun into yarn and woven into fabric, exhibit excellent thermal stability, chemical stability, flame retardancy, and electrical insulation. They also feature high porosity, large specific surface area, easy functional modification, and good structural controllability. PPS short fibers can be used to prepare PPS fiber membrane samples that meet the performance requirements for practical applications.

Zhongke Xingye has developed a comprehensive process technology and equipment solution for PPS short fiber preparation. The high-strength hydrophilic PPS short fibers produced, after being spun into yarn and woven into fabric, exhibit excellent thermal stability, chemical stability, flame retardancy, and electrical insulation. They also feature high porosity, large specific surface area, easy functional modification, and good structural controllability. PPS short fibers can be used to prepare PPS fiber membrane samples that meet the performance requirements for practical applications.

Zhongke Xingye has developed a comprehensive process technology and equipment solution for PPS short fiber preparation. The high-strength hydrophilic PPS short fibers produced, after being spun into yarn and woven into fabric, exhibit excellent thermal stability, chemical stability, flame retardancy, and electrical insulation. They also feature high porosity, large specific surface area, easy functional modification, and good structural controllability. PPS short fibers can be used to prepare PPS fiber membrane samples that meet the performance requirements for practical applications.Polyphenylene sulfide (PPS) is an important semi-crystalline thermoplastic resin. The PPS molecular backbone is formed by alternating benzene rings and sulfur atoms, with no side chains, which gives it good chain symmetry and regularity, thus providing it with good crystallization ability. The rigid structure of the benzene rings on the backbone makes its molecular chains relatively rigid, with a glass transition temperature of around 85°C, low creep, and high elastic modulus.

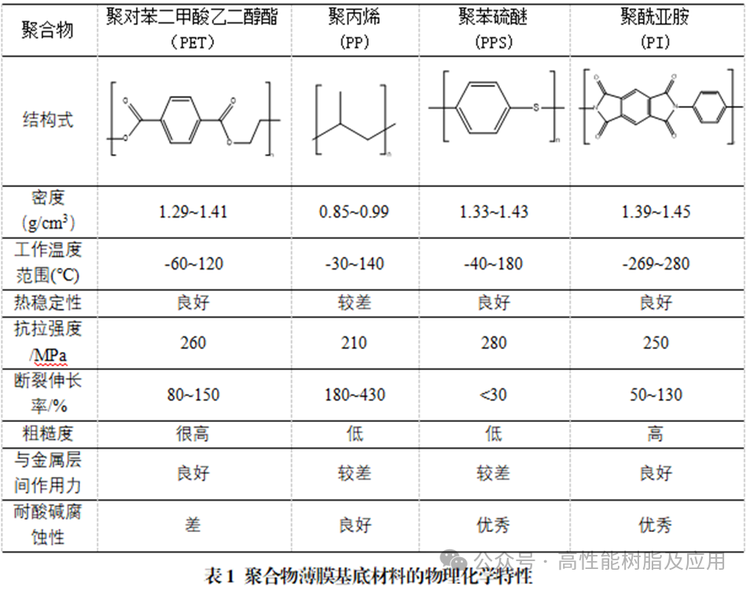

Polyphenylene sulfide (PPS) is an important semi-crystalline thermoplastic resin. The PPS molecular backbone is formed by alternating benzene rings and sulfur atoms, with no side chains, which gives it good chain symmetry and regularity, thus providing it with good crystallization ability. The rigid structure of the benzene rings on the backbone makes its molecular chains relatively rigid, with a glass transition temperature of around 85°C, low creep, and high elastic modulus.Comparison of Properties between PPS Film and Other Polymer Substrates

Comparison of Properties between PPS Film and Other Polymer SubstratesComparison of Properties between PPS Film and Other Polymer Substrates

Polyphenylene sulfide (PPS) film, with its excellent thermal stability, chemical resistance, electrical insulation, and mechanical properties, demonstrates significant application value across multiple high-end fields. The following is a summary of its main application areas and technical features:

1. Electrical Insulation Materials

PPS films have high insulation strength and low dielectric loss, making them widely used for the insulation protection of electronic components such as capacitor films, printed circuit board substrates, and wire wrapping materials. Their heat resistance (usable at temperatures above 200°C for long periods) makes them stand out in high-temperature electronic devices.

2. Electronic Components and Coating Substrates

Through surface treatment technologies, PPS films can be made into ultra-thin coating substrates, with surface roughness controlled to within 0.08μm, ensuring uniform coatings. These films are widely used in electronic packaging, conductive films, and shielding materials, such as integrated circuit packaging and electromagnetic shielding films.

3. Electrolytic Cell Membranes

In applications like hydrogen production by water electrolysis and chemical preparation, PPS films are used to manufacture electrolytic cell separators. Their high chemical resistance (tolerant to strong acids and bases) and low electrical conductivity effectively isolate the anode and cathode, enhancing electrolysis efficiency and prolonging equipment life.

4. Automotive and Industrial Components

Vaporization membranes: Used in automotive fuel system vaporizers, these are heat-resistant and resistant to medium corrosion.

Heat-resistant adhesive tapes: Used as masking materials in high-temperature environments around engines, capable of withstanding short-term exposure to 300°C.

5. Heat-Resistant Packaging and Specialty Materials

Food packaging: PPS films can be used in microwave-safe food packaging bags, being heat-resistant and non-toxic.

Aerospace: When combined with carbon fibers, they form lightweight structural materials for aircraft interiors or spacecraft components, offering both radiation resistance and flame retardancy.

6. Optical and Functional Films

PPS films can also be modified to create functional materials, such as: Thermal printing films: Utilizing their heat resistance for high-precision printing.

Absorptive materials: In military applications, they are used as electromagnetic wave-absorbing coatings to enhance stealth performance.

Polyphenylene sulfide (PPS) film, with its excellent thermal stability, chemical resistance, electrical insulation, and mechanical properties, demonstrates significant application value in various high-end fields. The following is a summary of its main application areas and technical characteristics:

1. Electrical Insulation Materials

PPS films feature high insulation strength and low dielectric loss, widely used for the insulation protection of electronic components such as capacitor films, printed circuit board substrates, and wire wrapping materials. Its heat resistance (usable up to 200°C or higher for long periods) makes it stand out in high-temperature electronic devices.

2. Electronic Components and Coating Substrates

Through surface treatment techniques, PPS films can be made into ultra-thin coating substrates, with surface roughness controllable within 0.08μm, ensuring uniformity of the coating. These films are extensively applied in electronic packaging, conductive films, and shielding materials, such as integrated circuit packaging and electromagnetic shielding films.

3. Electrolysis Cell Membranes

In applications like hydrogen production through water electrolysis and chemical preparation, PPS films are used to manufacture electrolysis cell separators. Their high chemical resistance (to strong acids and bases) and low electrical conductivity effectively isolate the anode and cathode, improving electrolysis efficiency and extending equipment life.

4. Automotive and Industrial Components

Vaporization membranes: Used in automotive fuel system vaporizers, they withstand high temperatures and resist medium corrosion.

Heat-resistant adhesive tapes: Serve as masking materials in high-temperature environments around engines, capable of withstanding short-term exposure to 300°C.

5. Heat-Resistant Packaging and Specialty Materials

Food packaging: PPS films can be used in microwave-safe food packaging bags, being both heat-resistant and non-toxic.

Aerospace: When combined with carbon fibers, they form lightweight structural materials for aircraft interiors or spacecraft parts, offering radiation resistance and flame retardancy.

6. Optical and Functional Films

PPS films can also be modified into functional materials, such as: Thermal sensitive copy films: Utilizing their heat resistance for high-precision printing.

Absorbing materials: In military applications, used as electromagnetic wave absorbing coatings to enhance stealth performance.

Polyphenylene sulfide (PPS) film, with its excellent thermal stability, chemical resistance, electrical insulation, and mechanical properties, demonstrates significant application value in various high-end fields. The following is a summary of its main application areas and technical characteristics:

1. Electrical Insulation Materials

1. Electrical Insulation Materials1. Electrical Insulation MaterialsPPS films feature high insulation strength and low dielectric loss, widely used for the insulation protection of electronic components such as capacitor films, printed circuit board substrates, and wire wrapping materials. Its heat resistance (usable up to 200°C or higher for long periods) makes it stand out in high-temperature electronic devices.

PPS film has high insulation strength and low dielectric loss, widely used in the insulation protection of electronic components, such as capacitor films, printed circuit board substrates, wire wrapping materials, etc. Its heat resistance (usable at temperatures above 200℃ for long periods) makes it stand out in high-temperature electronic devices.2. Electronic Components and Coating Substrates

2. Electronic Components and Coating Substrates2. Electronic Components and Coating SubstratesThrough surface treatment technology, PPS film can be made into ultra-thin coating substrates, with surface roughness controllable within 0.08μm, ensuring uniformity of the coating. Such films are widely used in electronic packaging, conductive films, and shielding materials, such as integrated circuit packaging, electromagnetic shielding films, etc.

Through surface treatment technology, PPS film can be made into ultra-thin coating substrates, with surface roughness controllable within 0.08μm, ensuring uniformity of the coating. Such films are widely used in electronic packaging, conductive films, and shielding materials, such as integrated circuit packaging, electromagnetic shielding films, etc.3. Electrolytic Cell Membranes

3. Electrolytic Cell Membranes3. Electrolytic Cell MembranesIn areas such as hydrogen production by water electrolysis and chemical preparation, PPS film is used to manufacture electrolytic cell separators. Its high chemical corrosion resistance (tolerant to strong acids and bases) and low electrical conductivity effectively isolate the anode and cathode, improving electrolysis efficiency and extending equipment life.

In areas such as hydrogen production by water electrolysis and chemical preparation, PPS film is used to manufacture electrolytic cell separators. Its high chemical corrosion resistance (tolerant to strong acids and bases) and low electrical conductivity effectively isolate the anode and cathode, improving electrolysis efficiency and extending equipment life.4. Automotive and Industrial Components

4. Automotive and Industrial Components4. Automotive and Industrial ComponentsVaporization Membrane: Used in the vaporization devices of automotive fuel systems, it is heat-resistant and resistant to medium corrosion.

Vaporization Membrane: Used in the vaporization devices of automotive fuel systems, it is heat-resistant and resistant to medium corrosion.Heat-Resistant Adhesive Tape: Used as a masking material in high-temperature environments around engines, capable of withstanding short-term temperatures up to 300℃.

Heat-Resistant Adhesive Tape: Used as a masking material in high-temperature environments around engines, capable of withstanding short-term temperatures up to 300℃.5. Heat-Resistant Packaging and Special Materials

5. Heat-Resistant Packaging and Special Materials5. Heat-Resistant Packaging and Special MaterialsFood Packaging: PPS film can be used in microwave heating food packaging bags, being heat-resistant and non-toxic.

Food Packaging: PPS film can be used in microwave heating food packaging bags, being heat-resistant and non-toxic.Aerospace: When combined with carbon fiber, it forms lightweight structural materials for aircraft interiors or spacecraft parts, featuring both radiation resistance and flame retardancy.

Aerospace: When combined with carbon fiber, it forms lightweight structural materials for aircraft interiors or spacecraft parts, featuring both radiation resistance and flame retardancy.6. Optical and Functional Films

6. Optical and Functional Films6. Optical and Functional FilmsPPS film can also be modified to produce functional materials, such as: Thermosensitive Copy Film: Utilizing its heat resistance to achieve high-precision printing.

PPS film can also be modified to produce functional materials, such as: thermal-sensitive copying film: utilizing its heat resistance for high-precision printing.Absorbing material: used in the military field for electromagnetic wave absorbing coatings, enhancing stealth performance

Absorbing material: used in the military field for electromagnetic wave absorbing coatings, enhancing stealth performance【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track