Silicone Precision Injection Molding Bubble Burrs? Sumitomo Injection Molding Machine's 5 Major Technologies Easily Break the Deadlock!

Silicone injection molding is a high-precision, high-efficiency forming method. Due to its excellent heat resistance, cold resistance, compressibility, and skin-like texture, it is widely used in fields such as automotive, maternal and infant products, medical care, and electronics.

Type C

LSR Injection Molding Specific Topics

1.Short shots, shrinkage, poor appearance, flash, and demolding issues caused by filling differences.

2.Due to differences in the surface pressure on the template PL (split type) surface, uneven material viscosity, and changes in viscosity over time, short shots, flash, and mold cavity balance deterioration occur.

3.Exhaust obstruction causing short material and scorching.

4.Mold deformation leads to a shorter mold lifespan.

Our all-electric injection molding machines offer highly precise technical solutions for the stable production of LSR products.

Sumitomo's solution technology

1.Eliminate filling variations through the SK3 set and high-precision injection molding control to achieve precise and stable injection molding.

2.By using a high-precision locking mechanism to achieve uniform pressure on the mold PL surface, the balance of the mold cavity is improved.

3.Using resin viscosity measurement functions to mitigate issues of material viscosity inconsistency and viscosity changes over time.

4.Control Circuit/Piping for Special Vacuum Pump + High-Precision Mold Pause Function

5.High-rigidity clamping unit + minimum clamping force detection function

Detailed Solution

1.Point 1: SK 3-piece set + high-precision injection molding control

Due to the low viscosity of LSR, the sealing of the three-piece screw set is crucial. The SK three-piece set can reverse-rotate the screw to close the resin flow path, suppress filling backflow, and ensure stable filling volume.

Additionally, high-precision injection molding control can be achieved through the standard direct drive system, enabling rapid and complete sealing functionality. As a result, even small-volume injection molding can attain precise and stable molding performance.

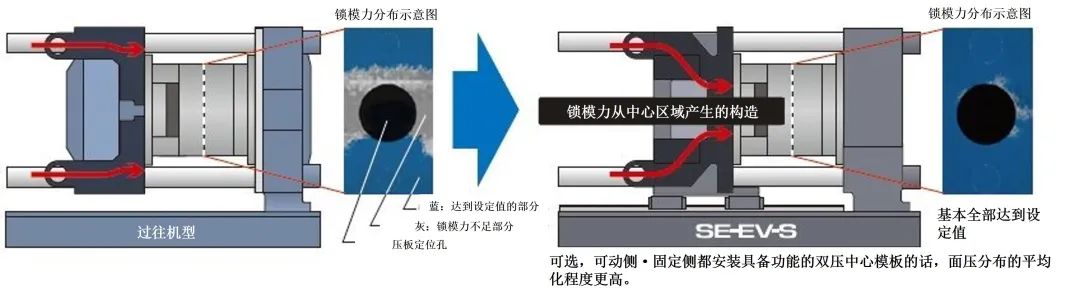

2.Point2:High-precision mode-locking mechanism

(Central Compression Template)

A standard clamping center template that enables uniform pressure distribution across the entire PL surface of the mold.

Reduce the difference in surface pressure in the central part of the mold and improve cavity balance.

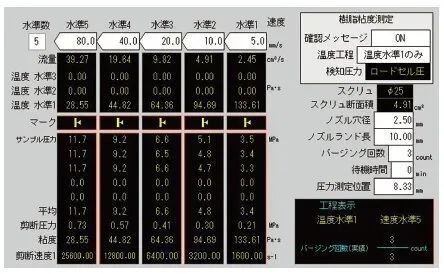

3.Point 3: Resin Viscosity Measurement Function

Sumitomo injection molding machines are equipped with a standard resin viscosity measurement function.

Resin viscosity measurement can be performed at any screw speed level.

Reduce production stability variations caused by differences between resin batches.

Please provide the content of "Point1" so I can accurately translate the detailed introduction of “SK3+” into English.

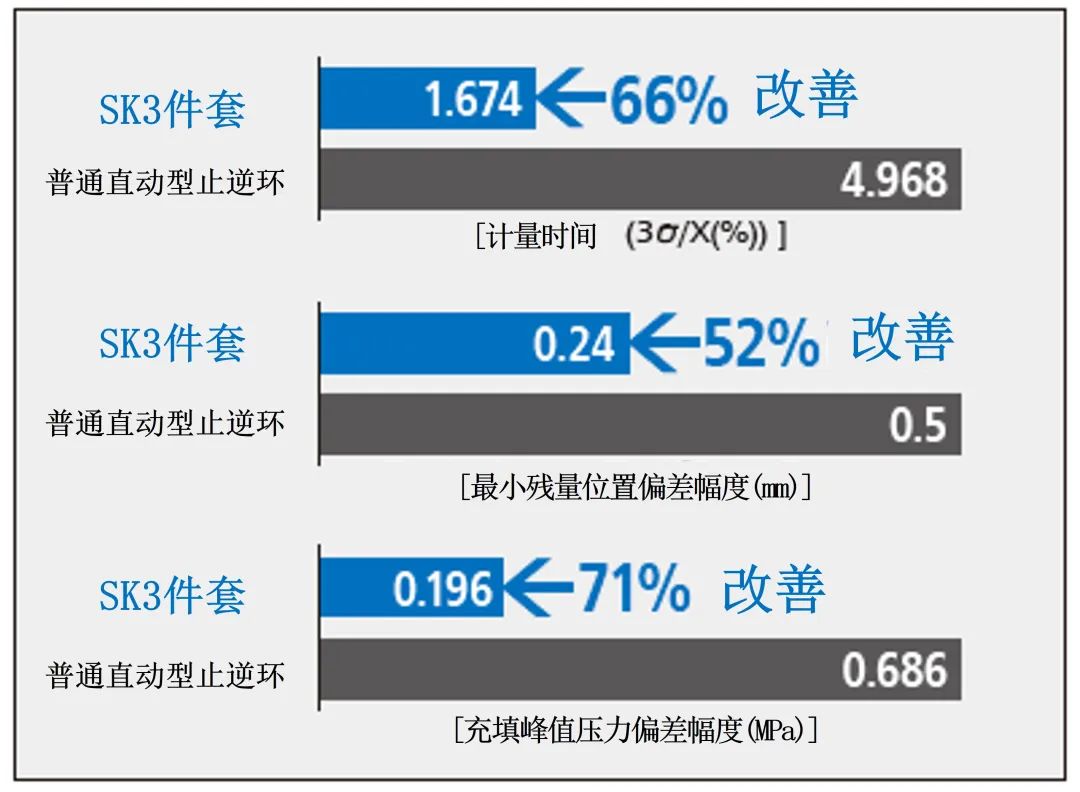

1.Improving injection molding precision and stability

Compared to the direct-acting check ring used in conventional LSR injection molding machines, the stability of metering and filling with the SK three-piece set has been significantly improved.

[Comparison of Precision Stable Walking]

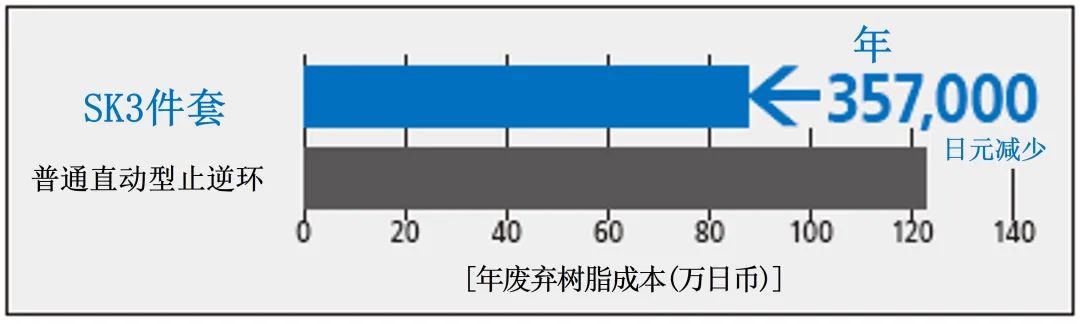

2.Reduction of waste resin

Improving yield rate through stable measurement reduces defective products = less discarded resin, significantly lowering production costs.

[Reduce waste resin costs]

※The resin values in the chart are actual measured values under the following conditions.

Injection Molded Product: Medical O-ring

Size: Outer diameter 44mm / Wire diameter 3mm

Modulus: 16

Product weight: 1.17g

Injection molding weight: 21.2g

Product Composition

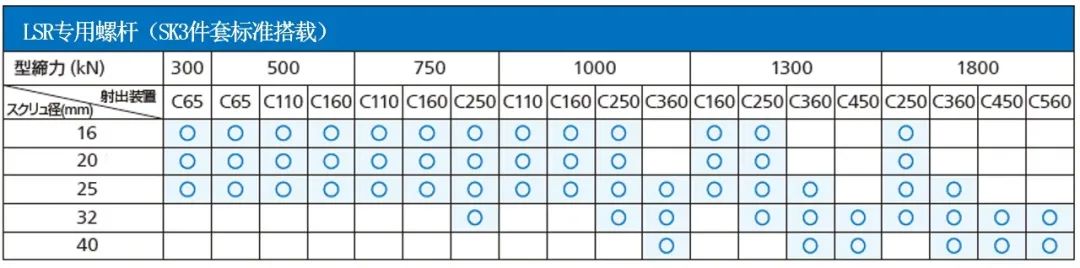

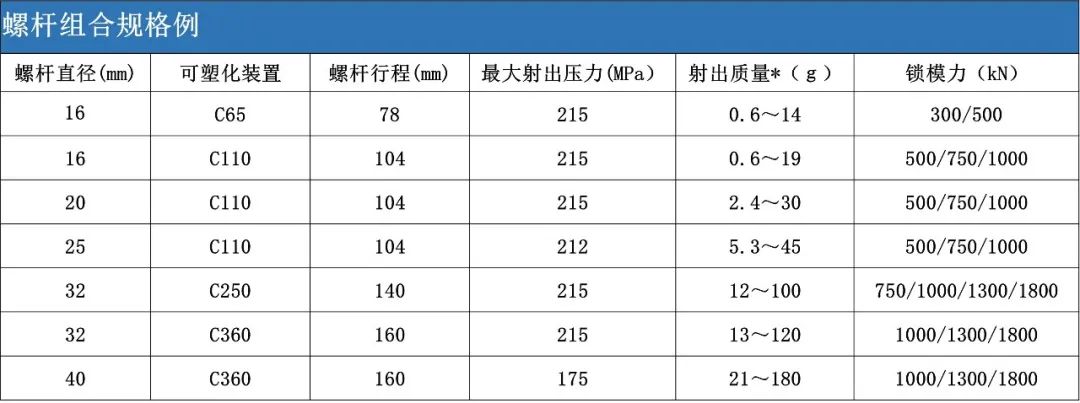

Based on the all-electric injection molding machine SE-EV-S series and equipped with a wide range of LSR-specific screws, the "LSR Injection Molding Package" is configured to meet the requirements of LSR injection molding. In addition, customized "optional specifications" are provided according to mold designs.

Build an optimization system that meets the requirements.

Detailed information about LSR injection molding kits and model selection can be provided upon request.

The injection quality is the standard value.

Other corresponding models

Corresponding to two-color injection molding and vertical injection molding.

Can correspond to LSR and heterogeneous material overmolding, vertical injection molding.

Expand the possibilities of LSR injection molding to assist in the development and production of new products.

Sumitomo injection molding machines integrate the latest technologies, offering a wide range of functions and model configurations to meet diverse product requirements, helping customers optimize production.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track