Showcasing Muscle! Automakers' Super Large Integrated Die-Casting Machines Frequently Unveiled, Why Integrated "Plastic" Parts Are Indispensable

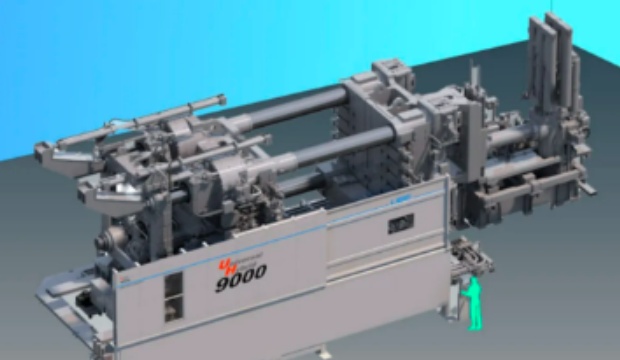

On September 8, Zhusuo Shijie reported that while news of the Dongfeng Motor's integrated die-casting industrialization construction project completing its final acceptance 25 days ahead of schedule was causing a stir, last weekend, BYD's Executive Vice President He Zhiqi posted on Weibo about BYD's 9,000-ton large die-casting production line. The front and rear cabin floors have transitioned from being welded from 74 stamped parts to becoming a single large die-cast aluminum piece, increasing efficiency and reducing weight. Moreover, the equipment is domestically produced, the molds are self-made, and the entire process is automated. Zhao Changjiang, General Manager of Denza's Direct Sales Division, reposted this saying that large die-casting represents a revolutionary technological change in the automotive manufacturing field, reshaping production models, enhancing efficiency, reducing costs, and improving performance. This development is just the tip of the iceberg in the domestic automotive companies' layout in the field of integrated die-casting.

Image source: He Zhiqi, BYD

Automakers Deploy Integrated Die Casting as a Technological Wave Sweeps In

Over the past year or so, domestic automakers have been making continuous moves in the field of integrated die-casting.

In December 2023, Xiaomi CEO Lei Jun unveiled the 9,100-ton Xiaomi Super Die-Casting Machine at the Xiaomi Automobile Technology Launch Event.

In February 2024, the Seres Super Factory will be completed and put into operation, equipped with a world-leading 9000T die-casting machine, achieving the highest level of integration for integrated die-casting components.

In September 2025, Dongfeng Motor's integrated die-casting industrialization construction project completed its acceptance inspection 25 days ahead of schedule. The project established the world's largest integrated die-casting dual production lines with 16,000-ton and 10,000-ton presses. Once operational, the project will significantly enhance the production capacity and efficiency of new energy vehicle manufacturing.

In addition, new cars such as AITO M9, Zeekr 007, and Xiaomi SU7 all adopt integrated die-casting technology, and new forces like XPeng, NIO, and Neta are also joining the layout. According to statistics, more than 20 domestic automakers have planned die-casting production capacity, and it is expected that by 2025, the global integrated die-casting market will exceed 30 billion yuan.

Internationally, Japan is also actively advancing integrated die-casting technology. In August last year, Toyota Motor Corporation announced that it would introduce a 9,000-ton large integrated die-casting machine manufactured by Ube Kosan Machinery in Aichi Prefecture, Japan, by 2025. This is one of the largest die-casting machines in Japan. However, compared with Japan, China has already gained a leading advantage in the field of integrated die casting. Dongfeng Motor introduced the world’s first 16,000-ton integrated die-casting technology, demonstrating China’s technological strength and efficient execution in the field of new energy vehicle manufacturing.

Image source: Toyota Motor Corporation

Under integrated die casting, plastics usher in new opportunities

Integrated die-casting technology uses ultra-large die-casting machines to form multiple parts in one go, revolutionizing traditional automobile manufacturing.The four major processes of "stamping - welding - painting - final assembly." Taking the Tesla Model Y as an example, the number of rear floor parts was reduced from 171 to 1, welding points decreased from 800 to 50, manufacturing costs were lowered by 40%, and production efficiency increased by 30%. This technology holds core value for the lightweighting of new energy vehicles, improvement of structural strength, and cost optimization.

However, integrated die-casting technology also faces numerous challenges. Technically, it is necessary to optimize alloy composition to suppress pre-crystallization and to ensure vacuum levels in order to improve mechanical properties. Tesla, for example, encountered such issues in the early stages.A 60% defect rate. In terms of cost, the equipment investment is enormous, and consumers are concerned about maintenance costs. Integrated die-cast parts need to be entirely replaced after a collision, which may lead to a sharp increase in repair expenses. These challenges are driving automakers to continuously make breakthroughs in material innovation and process optimization.

In the wave of integrated die casting dominated by metal materials, plastics are creating new opportunities through differentiated applications, with their core opportunities reflected in two main scenarios.

Source: China Machine Press

NVH Performance Optimization: Addressing the "Cavity Shortcomings" of Metal Die Casting

While integrated die-casting enhances the structural strength of the car body, the cavities formed within the car's white body can easily trigger vibration loops, worsening the situation.NVH Performance: Traditional solutions typically involve post-production remedies, such as adding sound-absorbing cotton after the vehicle body has been formed. In contrast, plastics can be incorporated earlier in the design process. For example, in the Tesla Model Y, PA66 nylon-based barrier blocks are pre-installed in the side cavity. During the electrophoretic baking process, these blocks foam and expand to form a continuous sealing layer, effectively isolating noise transmission. This "pre-embedded" solution is more efficient and lightweight than adding sound-absorbing materials later, providing a new approach for the application of plastics in automotive NVH fields.

Lightweighting and functional integration: replacing metals"Cost Reduction and Efficiency Improvement" Pathway

Tesla has replaced aluminum alloy with nylon reinforced with glass fiber composites in components such as door interior panels, audio-visual systems, and suspension systems. These materials not only reduce weightA weight reduction of 30% to 50% can be achieved, and functions such as wiring harnesses and sensors can also be integrated through injection molding processes, reducing assembly procedures. For example, by using plastic for the battery pack cover, sealing failures caused by differences in the thermal expansion coefficients of metal components can be avoided, while also reducing electromagnetic shielding costs. The lightweight and functional integration characteristics of plastics make them an important pathway for replacing metals, achieving cost reduction, and increasing efficiency.

The integration of die casting and plastic applications is essentially a collaborative innovation in material science. Metal castings provide a more regular mounting interface for plastics, simplifying the design complexity of plastic components. Plastics, by filling cavities and isolating vibrations, compensate for the shortcomings of metal castings in acoustic performance. This kind of...The combination of "rigidity and flexibility" is becoming a new paradigm for cost reduction and efficiency improvement in new energy vehicles.

Dongfeng MotorThe completion of a 16,000-ton die-casting factory is a vivid illustration of China's new energy vehicle industry transitioning from "scale expansion" to "technology-driven." In the face of the challenges of balancing cost and performance brought by integrated die-casting, plastics, with their unique material characteristics, demonstrate irreplaceable value in areas such as NVH optimization and lightweight integration. In the future, with advances in CAE simulation technology and the reduction in composite material costs, plastics are expected to become a key bridge connecting metal die-casting and intelligent electrification, injecting new momentum into the high-quality development of the automotive industry and promoting automotive manufacturing towards more efficient, environmentally friendly, and intelligent directions.

【Copyright and Disclaimer】This article is the property of PlastMatch. For business cooperation, media interviews, article reprints, or suggestions, please call the PlastMatch customer service hotline at +86-18030158354 or via email at service@zhuansushijie.com. The information and data provided by PlastMatch are for reference only and do not constitute direct advice for client decision-making. Any decisions made by clients based on such information and data, and all resulting direct or indirect losses and legal consequences, shall be borne by the clients themselves and are unrelated to PlastMatch. Unauthorized reprinting is strictly prohibited.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track