Abstract: The post-warping deformation of polybutylene terephthalate (PBT)/polyethylene terephthalate (PET) engineering plastic alloys after injection molding in thermal environments severely restricts their application in the automotive field. Using a 30% mass fraction of glass fiber-reinforced PBT/PET alloy, different glass fiber-reinforced PBT/PET composite samples were prepared by adding five different functional additives: zinc stearate, tetrabutyl titanate, disodium dihydrogen pyrophosphate (DHPP), nucleating agent, and sodium carbonate. The post-warping deformation behavior of the samples was evaluated, and the microscopic mechanisms were studied in-depth using differential scanning calorimetry and Fourier transform infrared spectroscopy, providing a reference for improving the dimensional stability of the material. The results show that the post-warping deformation mainly originates from the conformational transformation of the PET component's molecular chains and the improvement in crystal perfection. Different additives have significantly different impacts on the post-warping deformation of the samples: zinc stearate and sodium carbonate significantly inhibit deformation (reducing the deformation from 0.50 cm in samples without additives to 0.003 cm and 0.08 cm, respectively), tetrabutyl titanate moderately reduces deformation (0.24 cm), while DHPP and the nucleating agent severely exacerbate deformation (with deformation reaching 1.00 cm and 0.84 cm, respectively). Zinc stearate improves the mobility of molecular chains through a lubrication effect, enhancing the perfection of PET crystallization at demolding, and reducing the conformational transformation during subsequent heat treatment. Tetrabutyl titanate reduces PET crystallization capacity by promoting transesterification, while DHPP inhibits transesterification, maintaining high PET crystallization capacity. Furthermore, the final deformation levels of samples with the same formulation were consistent under different simulated conditions such as constant temperature annealing at 80°C, alternating high and low temperature cycles, and sunlight exposure, indicating a certain determinacy in the final deformation state of specific glass fiber-reinforced PBT/PET composites. The research findings provide a reference for the stable application of PBT/PET alloys in the new energy vehicle field.

Keywords: Polybutylene terephthalate/polyethylene terephthalate alloy; post-warping deformation; dimensional stability; molecular chain conformation; additives

Polybutylene terephthalate (PBT) and polyethylene terephthalate (PET) alloys are a class of engineering plastic alloys that combine the excellent processing properties of PBT with the high rigidity and heat resistance of PET.[1-4]PBT/PET alloys can achieve complementary and synergistic enhancement of the properties of the two polyester materials through blending, compatibilization, and other means, exhibiting excellent performance.[5-7]Compared with traditional nylon (PA) materials, glass fiber (GF) reinforced PBT/PET alloy composites offer significant cost advantages while maintaining comparable mechanical properties and heat resistance.[8-10]Based on these advantages, glass fiber-reinforced PBT/PET composites have been widely used in the field of new energy vehicles in recent years, especially in key components such as domain controllers and front windshield controllers, where cost sensitivity and strict performance requirements are critical. These composites have gradually replaced traditional materials such as PA6 and PA66, becoming an important material choice for new energy vehicles.[11-13]。

However, as a typical semicrystalline polymer material, semicrystalline polyester materials exhibit significant volumetric shrinkage characteristics during the molding process. Especially for glass fiber reinforced semicrystalline polyester materials, anisotropy caused by fiber orientation and uneven shrinkage during the crystallization process make the products prone to severe warpage deformation.[14-16]At present, numerous studies have focused on the warpage behavior of semi-crystalline polyester materials during the demolding stage, such as the work by Hu Zhigang and others.[15]The effect of calcium sulfate whiskers on the warpage of glass fiber reinforced PBT materials was studied by Rong Luo.[16]The relationship between injection molds and the warpage deformation of PBT has been discussed. However, in practical applications, a troublesome issue faced by such materials is the occurrence of “post-warpage deformation” during use. With the periodic temperature changes in the automotive engine compartment (especially the local temperature increase caused by direct sunlight), glass fiber reinforced PBT/PET composite products often undergo significant changes in size and shape, which seriously affect the assembly precision and even the functional integrity of components. Nevertheless, systematic research on this post-deformation behavior remains insufficient in related fields, especially with a lack of quantitative characterization methods and mechanistic analysis, which restricts the application development and performance optimization of glass fiber reinforced PBT/PET composites.

Based on the aforementioned background, the author intends to establish an accurate three-dimensional evaluation method for the post-warping deformation of glass fiber-reinforced PBT/PET composites. This involves systematically investigating the influence of different additives on the post-deformation behavior of these composites. Through structural characterization, an in-depth analysis of the microscopic mechanism of post-warping deformation in glass fiber-reinforced PBT/PET composites will be conducted. Additionally, various actual service conditions (constant temperature annealing, high-low temperature alternating cycles, and sunlight irradiation) have been simulated to study their impact on the deformation behavior of the materials. This provides a theoretical foundation and experimental basis for the targeted design and performance optimization of glass fiber-reinforced PBT/PET composites in new energy vehicle components.

PBT: GX112, Sinopec Yizheng Chemical Fibre Company Limited;

PET: FG600, Sichuan Dongfang Insulating Material Co., Ltd.

Chopped glass fiber: ECS3F-03-534A, diameter 10 μm, length 3 mm, China Jushi Co., Ltd.

Zinc stearate: BS-2818, Tianjin Langhu Technology Co., Ltd.

Tetrabutyl titanate [Ti(OBu)4], disodium dihydrogen pyrophosphate (DHPP), sodium carbonate (Na2CO3China National Pharmaceutical Group Chemical Reagent Co., Ltd.;

Nucleating agent: P250, Brϋggemann, Germany.

1.2 Main Instruments and Equipment

Twin-screw extruder pelletizing machine: Berstorff ZE25, KraussMaffei Machinery (Zhejiang) Co., Ltd.;

Injection molding machine: HTB110X/1, Haitian Plastic Machinery Group Co., Ltd.;

Environmental Chamber: ATST-80-40-W, Dongguan Yadong Instrument Equipment Co., Ltd.

Fourier Transform Infrared Spectrometer (FTIR): Paragon 1000, PerkinElmer Instruments, USA.

Differential Scanning Calorimeter (DSC): TQ 2000, TA Instruments, USA.

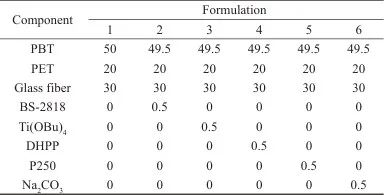

First, PBT and PET resins were dried in a vacuum oven at 120 °C for 4 hours to remove moisture from the materials and prevent thermal degradation during processing. Then, according to the experimental formulation proportions (see Table 1), various resins and additives were accurately weighed and thoroughly mixed. Subsequently, the blended raw materials were fed into a twin-screw extruder for melt blending. Glass fibers were side-fed to ensure uniform fiber dispersion and reduce fiber breakage. The temperatures of the extruder zones from the feeding section to the die were set sequentially at 35, 220, 230, 240, 250, 260, 270, and 280 °C, with a screw speed of 500 r/min. The extruded melt was cooled by water and pelletized to obtain composite material pellets.

Table 1 Mass fraction of components in glass fiber reinforced PBT/PET composites (%)

The prepared composite material particles are placed in a vacuum oven at 120°C to dry for 4 hours in order to remove moisture. Subsequently, the material is injection molded using an injection molding machine to prepare the hot runner plate shell required for the experiment. The injection-molded hot runner plate shell samples are designed with thin walls, with a thickness of only 2 mm, in a flat rectangular shape with dimensions of 400 mm × 200 mm × 2 mm. This typical rectangular thin-wall structure makes it particularly suitable for post-warping deformation assessment, effectively reflecting the dimensional stability issues of the material in practical applications. The temperature settings of the injection molding machine range from the feed section to the nozzle at 280, 275, 270, 265, and 260°C, respectively, with the injection pressure controlled within the range of 40 to 70 MPa.

The five additives selected by the author each have specific functions: zinc stearate (BS-2818) serves as a lubricant to improve the material’s processing fluidity and demoldability, enhancing the surface smoothness of the product; Ti(OBu)4It is a transesterification promoter that facilitates the transesterification reaction of PBT/PET alloys and also improves the compatibility between the alloy and glass fiber; DHPP, as a transesterification inhibitor, can prevent the transesterification reaction of PBT/PET alloys during processing; nucleating agents P250 and Na.2CO3The crystallization of materials can be promoted. The author sets the mass fraction of each additive uniformly at 0.5%, based on the following considerations: (1) It facilitates a systematic comparison of the individual effects of different additives, eliminating variables arising from differences in addition amounts; (2) 0.5% is a commonly used medium addition level for these additives in engineering plastics, which can demonstrate efficacy while avoiding the side effects of excessive addition; (3) In practical applications, although these additives may be used in combination, it is first necessary to clarify the individual action mechanism of each additive to provide a theoretical basis for the design of subsequent compound formulations.

1.4 Testing and Characterization

DSC Test: Sample specific locations of the specimen and conduct DSC testing under nitrogen protection (nitrogen flow rate of 20 mL/min). Place 5~10 mg of the sample in an aluminum sample pan and heat it from 30 ℃ to 300 ℃ at a rate of 10 ℃/min, recording the enthalpy change during the heating process.

FTIR analysis test: The test was conducted using the Attenuated Total Reflectance (ATR) mode, with a scan range of 4000~600 cm⁻¹.-1The resolution is set to 4 cm.-1Each sample is cumulatively scanned 32 times to improve the signal-to-noise ratio.

The posterior warp deformation test adopts a self-designed three-dimensional evaluation method, as detailed in section 2.1. The testing environment is an environmental chamber that allows precise control of parameters such as temperature and humidity. The specific parameters for the three simulated working conditions are as follows.

(1) 80°C isothermal annealing: in a constant temperature oven for 24 hours.

(2) High and low temperature alternating cycles: In accordance with automotive industry standards, the complete thermal cycle includes 14 hours at 40°C with 95% humidity, 4 hours at 40°C in a dry environment, and 6 hours at 85°C in a high-temperature environment.

(3) Simulated sunlight irradiation: A xenon lamp was used as the light source for continuous irradiation for 24 hours.

2.1 Establishment of a Three-Dimensional Evaluation Method for Posterior Warping Deformation

Currently, the warpage deformation of polymer materials is mainly evaluated using the plate method. In this approach, a square plate specimen is placed horizontally on a table, and a 500 g weight is applied to one corner; the height between the opposite corner and the table surface is then measured. However, the plate method is essentially a visual assessment technique that lacks quantitative testing capability. As a result, the accuracy and repeatability of the test results are poor, making it difficult to meet the precise analytical requirements for warpage deformation in complex structural components. In addition, existing research has mainly focused on the initial warpage behavior of polymer products during demolding, while insufficient attention has been paid to the subsequent deformations that occur under actual service conditions. This oversight may lead to erroneous evaluation of the material’s real-world performance, as polymers—especially semi-crystalline polyesters such as PBT/PET alloys—often undergo significant dimensional changes and morphological evolution under coupled thermal, moisture, and mechanical stresses. Such changes affect dimensional stability, fitting clearance, stress distribution, and may even cause functional failure of the product, ultimately shortening its service life. Therefore, establishing a three-dimensional evaluation method for post-warpage deformation is of great significance for the development of high-performance, low-deformation materials.

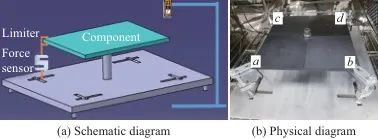

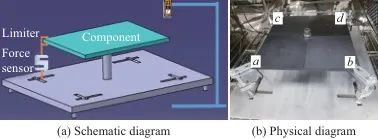

In response to the aforementioned issue, the author focuses on the hot runner plate shell and proposes a three-dimensional quantitative evaluation method based on multi-point displacement monitoring, as shown in Figure 1. The specific description is as follows.

Fig. 1 3D evaluation method of post-warpage deformation

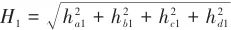

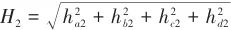

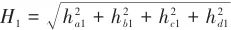

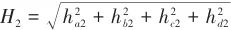

First, mount the injection-molded hot runner manifold shell onto a dedicated experimental fixture, which consists of a reference plane and limiters. This fixture is used to precisely measure the distance between the four corners of the manifold shell and the reference plane, ensuring accurate evaluation of the sample's dimensional stability in its natural state. Measure the four corner points of the manifold shell.a,b,c,d )Distance from the reference plane(ha1,hb1,hc1,hd1Calculate the initial warping deformation according to formula (1).H1。

Fig. 1 3D evaluation method of post-warpage deformation

First, mount the injection-molded hot runner manifold shell onto a dedicated experimental fixture, which consists of a reference plane and limiters. This fixture is used to precisely measure the distance between the four corners of the manifold shell and the reference plane, ensuring accurate evaluation of the sample's dimensional stability in its natural state. Measure the four corner points of the manifold shell.a,b,c,d )Distance from the reference plane(ha1,hb1,hc1,hd1Calculate the initial warping deformation according to formula (1).H1。

|

|

|

(1) |

Subsequently, the samples are subjected to specific environmental conditions (such as controlled temperature, humidity, etc.) to simulate actual usage environments. After the treatment is completed, the distances between the four corner points and the reference plane are measured again.ha2,hb2,hc2,hd2), and calculate the deformation amount according to formula (2)H2。

|

|

|

(2) |

Finally, the warpage deformation Δ of the sample under the target condition is calculated using equation (3).H。

|

|

|

(3) |

2.2 The Influence of Different Additives on the Warpage Deformation of Glass Fiber Reinforced PBT/PET Composites

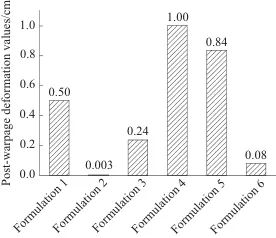

To study the effect of different additives on the post-warping deformation of glass fiber reinforced PBT/PET composites, the samples of each formulation were placed at 80°C for 24 hours before testing. The results are shown in Figure 2. The results in Figure 2 indicate that different additives cause significant differences in the post-warping deformation of the samples. As shown in Figure 2, the sample with the addition of zinc stearate BS-2818 exhibited the smallest post-warping deformation (0.003 cm), indicating that zinc stearate significantly improves the dimensional stability of glass fiber reinforced PBT/PET composites. The next best performance was observed in samples with the addition of Na...2CO3The deformation of the sample is only 0.08 cm. Adding Ti(OBu)4The sample showed a warpage deformation of 0.24 cm after molding, significantly lower than that of the sample with formulation 1 (0.50 cm). It is noteworthy that the sample with added DHPP exhibited the largest warpage deformation (1.00 cm). The sample with nucleating agent P250 also showed a relatively large warpage deformation (0.84 cm).

Fig. 2 Post-warpage deformation of samples from different formulations after being placed at 80 ℃ for 24 h

2.3 Analysis of the Warpage Deformation Mechanism of Glass Fiber Reinforced PBT/PET Composites

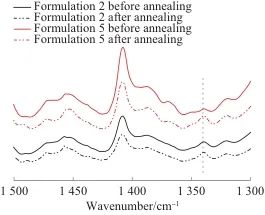

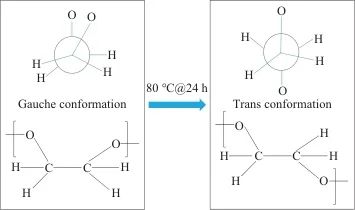

Based on the above test results of post-warping deformation, it was found that different additives have a significant impact on the dimensional stability of glass fiber reinforced PBT/PET composites. To further reveal the underlying reasons behind these phenomena, samples with relatively small post-warping deformation (Formula 2, with BS-2818 added) and samples with relatively large post-warping deformation (Formula 5, with P250 added) were selected for comparative analysis. Figure 3 shows the FTIR curves of Formula 2 and Formula 5 samples before and after annealing at 80°C. As can be seen from Figure 3, after annealing, the sample of Formula 5 with larger post-warping deformation shows that its absorption peak at 1,340 cm-1The intensity of the characteristic peak at this position increased significantly, whereas no similar change was observed in the formulation 2 sample with less rear warpage deformation.-1The infrared characteristic peak at the site is attributed to the trans conformation of the ethylene glycol segments in the PET molecular chain. The ethylene glycol segments in the PET molecules can exist in either the trans conformation or the gauche conformation, as shown in Figure 4. For the formulation 5 sample, the thermal energy provided by annealing treatment promotes the rearrangement of the PET molecular chains, preferentially forming the trans conformation with smaller steric hindrance and greater stability.

Fig. 3 FTIR spectra of samples from formulation 2 and formulation 5 before and after annealing at 80 ℃

Fig. 4 Mechanism of conformational transition of ethylene glycol chain segment in PET molecules

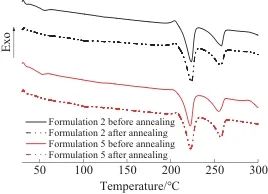

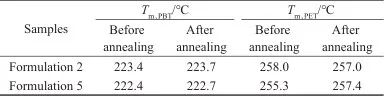

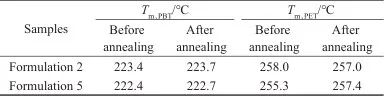

In addition, the first DSC heating curves before and after annealing for formulations 2 and 5 were compared, as shown in Figure 5, and the changes in the melting temperatures of PBT and PET phase crystals in the two samples were summarized (see Table 2). The results indicate that for both samples, the melting temperature of PBT crystals showed no significant change before and after annealing. However, for formulation 2, which exhibited less warpage deformation, the melting temperature of PET crystals slightly decreased from 258.0 °C before annealing to 257.0 °C after annealing; whereas for formulation 5, which exhibited greater warpage deformation, the melting temperature of PET crystals significantly increased from 255.3 °C before annealing to 257.4 °C after annealing. The increase in PET melting temperature suggests that the crystal structure of the PET phase in formulation 5 became more ordered after annealing treatment.

Fig. 5 DSC heating curves of samples from formulation 2 and formulation 5 before and after annealing at 80 ℃

Table 2 Melting temperatures of samples from Formulation 2 and Formulation 5 before and after annealing at 80°CTm)Tab. 2 Melting temperature (Tm) of samples from formulation 2 and formulation 5 before and after 80 ℃ annealing

For PBT/PET alloys, due to the relatively slow crystallization rate of PET, its crystallization is often incomplete at the time of demolding, resulting in unstable molecular chain conformations. After heat treatment, the conformation of PET molecular chains gradually transforms from the gauche conformation to the more stable trans conformation, leading to a more perfect crystal structure. However, this also causes anisotropic shrinkage, which in turn induces post-molding warpage deformation. In contrast, in formulation 2, the addition of zinc stearate BS-2818, through its lubricating effect, enhances the mobility of molecular chains. This enables a higher degree of crystallinity in PET at the time of demolding and increases the flexibility of PET molecular chains during the annealing process, thereby reducing the accumulation of internal stress and significantly decreasing the amount of post-molding warpage. These results indicate that the addition of BS-2818 plays an important role in improving the dimensional stability of glass fiber reinforced PBT/PET composites. Ti(OBu)4By promoting the transesterification reaction of the PBT/PET alloy, the regularity of the PET segments is reduced, thereby inhibiting the crystallization ability of PET and reducing the post-warpage deformation of the material. In contrast, DHPP inhibits the transesterification reaction of the PBT/PET alloy and maintains the crystallization ability of the PET component, which increases the amount of post-warpage deformation of the material. The addition of nucleating agent P250 causes PET to form imperfect crystal structures, which tend to become more perfect after annealing treatment. This is evidenced by the increase in melting temperature, and the perfection of the crystals leads to post-warpage deformation of the material.

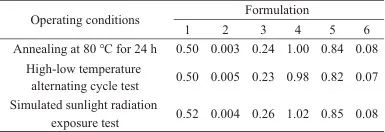

In actual application scenarios of parts, environmental conditions are complex and variable, including storage and transportation, sun exposure, and various experimental tests. Therefore, comprehensively evaluating the post-warp deformation behavior of parts under different environmental conditions is crucial to meeting stringent customer requirements. Based on this consideration, in addition to the standard condition of annealing at 80 ℃ for 24 hours, the author also designed two evaluation schemes simulating actual application environments, namely high-low temperature alternating cycle tests and simulated sunlight irradiation tests. Specific test parameters are shown in section 1.4, and test results are presented in Table 3. It is worth noting that samples with the same formulation underwent different thermal histories under the three conditions, yet their final post-warp deformation amounts remained basically consistent. This phenomenon indicates that for glass fiber reinforced PBT/PET composites with specific compositions, regardless of the thermal treatment conditions experienced, their final deformation states exhibit similarity.

For PBT/PET alloys, due to the relatively slow crystallization rate of PET, its crystallization is often incomplete at the time of demolding, resulting in unstable molecular chain conformations. After heat treatment, the conformation of PET molecular chains gradually transforms from the gauche conformation to the more stable trans conformation, leading to a more perfect crystal structure. However, this also causes anisotropic shrinkage, which in turn induces post-molding warpage deformation. In contrast, in formulation 2, the addition of zinc stearate BS-2818, through its lubricating effect, enhances the mobility of molecular chains. This enables a higher degree of crystallinity in PET at the time of demolding and increases the flexibility of PET molecular chains during the annealing process, thereby reducing the accumulation of internal stress and significantly decreasing the amount of post-molding warpage. These results indicate that the addition of BS-2818 plays an important role in improving the dimensional stability of glass fiber reinforced PBT/PET composites. Ti(OBu)4By promoting the transesterification reaction of the PBT/PET alloy, the regularity of the PET segments is reduced, thereby inhibiting the crystallization ability of PET and reducing the post-warpage deformation of the material. In contrast, DHPP inhibits the transesterification reaction of the PBT/PET alloy and maintains the crystallization ability of the PET component, which increases the amount of post-warpage deformation of the material. The addition of nucleating agent P250 causes PET to form imperfect crystal structures, which tend to become more perfect after annealing treatment. This is evidenced by the increase in melting temperature, and the perfection of the crystals leads to post-warpage deformation of the material.

In actual application scenarios of parts, environmental conditions are complex and variable, including storage and transportation, sun exposure, and various experimental tests. Therefore, comprehensively evaluating the post-warp deformation behavior of parts under different environmental conditions is crucial to meeting stringent customer requirements. Based on this consideration, in addition to the standard condition of annealing at 80 ℃ for 24 hours, the author also designed two evaluation schemes simulating actual application environments, namely high-low temperature alternating cycle tests and simulated sunlight irradiation tests. Specific test parameters are shown in section 1.4, and test results are presented in Table 3. It is worth noting that samples with the same formulation underwent different thermal histories under the three conditions, yet their final post-warp deformation amounts remained basically consistent. This phenomenon indicates that for glass fiber reinforced PBT/PET composites with specific compositions, regardless of the thermal treatment conditions experienced, their final deformation states exhibit similarity.

Tab. 3 Post-warpage deformation values of samples from different formulations under three different operating conditions (cm)

3. Conclusion

(1) A three-dimensional evaluation method for warpage deformation was established, which quantitatively characterizes the warpage deformation of complex structural parts by accurately measuring the distances between the four corner points of the hot runner plate shell and the reference plane.

(2) Different additives have a significant impact on the warpage deformation of glass fiber reinforced PBT/PET composites. Zinc stearate BS-2818 is the most effective, reducing the warpage deformation of the samples to 0.003 cm. Na2CO3Next (0.08 cm), Ti(OBu)4Also performed well (0.24 cm), while DHPP and nucleating agent P250 caused the maximum and relatively large warpage deformation amounts (1.00 cm and 0.84 cm), respectively.

The warpage deformation mechanism of glass fiber reinforced PBT/PET composites is attributed to the crystallization behavior of the PET component and the conformational changes of molecular chains. Zinc stearate enhances the mobility of molecular chains through its lubricating effect, improves the degree of PET crystallization at demolding, and effectively reduces the accumulation of internal stress, thereby suppressing warpage deformation.

The final post-warping deformation of glass fiber reinforced PBT/PET composites with the same formulation remains essentially consistent under three different simulated conditions: constant temperature annealing at 80 °C, alternating high and low temperature cycles, and sunlight irradiation.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.