Settlement reached: DuPont, Chemours, and Corteva to Pay Over 6 Billion in Compensation

On August 4th, Chemours, DuPont, and Corteva announced a settlement with the state of New Jersey, agreeing to pay $875 million (approximately 6.29 billion RMB) to resolve claims related to per- and polyfluoroalkyl substances (PFAS) pollution.

According to the agreement, this settlement will resolve all legacy pollution claims related to the existing and historical operational sites of the three companies (including Chambers Works, Parlin, Pompton Lakes, and Repauno), as well as all claims related to PFAS pollution throughout the state of New Jersey. The settlement amount will be paid over 25 years, with $16.5 million of the total settlement amount allocated to resolve PFAS pollution claims not related to the operational sites of the three companies (including $4.125 million related to aqueous film-forming foam).

Additionally, the three companies have established a governance fund of up to $1.2 billion and a reserve fund of $475 million to guard against future bankruptcy or default.

According to the Memorandum of Understanding signed by all parties in January 2021, Chemours will bear 50% of the settlement amount, approximately $250 million; DuPont will bear 35.5%, approximately $177 million; and Corteva will bear the remaining 14.5%, approximately $72 million.

DuPont just compensated approximately 190 million yuan last month.

On July 11, DuPont agreed to pay a settlement of $27 million (approximately 190 million RMB) to resolve a nearly decade-long water contamination lawsuit in a village in northern New York State, with an additional $6 million allocated for a medical monitoring program for current residents who have been exposed.

In this case, Saint-Gobain Performance Plastics, Honeywell International, and 3M reached a settlement in 2021, with a total amount exceeding $65 million. DuPont is the last remaining defendant.

In this class action, it is reported that a local Teflon fabric coating plant operated by Saint-Gobain and Honeywell caused drinking water to be contaminated with perfluorooctanoic acid (PFOA). DuPont provided the Teflon materials used at the plant, while 3M supplied the PFOA used in DuPont's products. Both companies were sued in 2018.

PFOA is a type of PFAS chemical, which is used in non-stick products such as Teflon. It is associated with various serious diseases, including kidney cancer and testicular cancer.

DuPont and Teflon

Public records show that DuPont has incurred multiple compensations and penalties due to PFAS pollution issues.

DuPont has been continuously purchasing PFOA produced by 3M since 1951 for the production of Teflon.

In 2005, the United States Environmental Protection Agency imposed a $16.5 million fine on DuPont due to PFOA. Subsequently, DuPont promised to completely phase out the use of PFOA, which is used to make Teflon, by 2015 and to reduce PFOA emissions.

In 2017, DuPont and Chemours reached a settlement to pay $671 million to resolve thousands of lawsuits related to PFOA leaks.

In 2020, a cancer survivor named Abbott sued DuPont after developing testicular cancer twice due to years of exposure to PFAS produced by the company and was ultimately awarded a $40 million settlement from DuPont.

In June 2023, DuPont, Chemours, and Corteva reached a settlement agreement worth $1.18 billion to resolve complaints from approximately 300 drinking water providers regarding PFAS. Chemours contributed approximately $592 million, DuPont contributed $400 million, and Corteva contributed $193 million.

Multiple companies face claims for compensation.

In recent years, multiple states in the United States have filed lawsuits against companies responsible for PFAS pollution, accusing them of causing large-scale environmental pollution and of concealing evidence of its dangers for decades. Several companies have begun to settle these cases.

3M Company, a supplier of DuPont, has faced multiple lawsuits:

In May, its Cynthiana plant in Kentucky received a subpoena from the Kentucky Energy and Environment Cabinet, requesting information about the plant's use and emission of PFAS and other potentially hazardous substances. Additionally, the regulatory agency instructed 3M to develop a plan to investigate potential PFAS emissions from the plant.

In the same month, it was also announced that a settlement had been reached with the state of New Jersey regarding PFAS-related claims, with a total amount of $450 million.

In addition, it reached a settlement with U.S. public water suppliers in March 2024, agreeing to pay up to $10.3 billion over 13 years to help clean up the contamination of drinking water with "forever chemicals." It is worth mentioning that 3M Company has stated that it will exit all PFAS manufacturing by the end of 2025.

In addition to 3M Company, BASF Corporation, the North American subsidiary of BASF, reached a settlement in 2024 regarding PFAS contamination with public water systems across the United States, agreeing to contribute $316.5 million.

Solvay USA Inc. reached a settlement with the state of New Jersey in 2023, under which Solvay will pay $175 million to the New Jersey Department of Environmental Protection ($75 million as compensation for natural resource damages and $100 million to fund remediation efforts in the area surrounding the West Deptford plant).

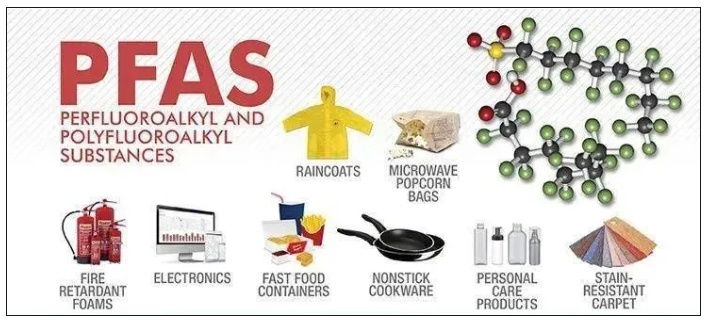

What is PFAS?

PFAS, or per- and polyfluoroalkyl substances, are a series of synthetic organic compounds that do not occur naturally. They are primarily composed of carbon and fluorine atoms. The most extensively studied compounds include perfluorooctanoic acid (PFOA), perfluorooctane sulfonic acid (PFOS), and hexafluoropropylene oxide dimer acid (GenX), which are characterized by excellent thermal stability, resistance to degradation, fire resistance, and persistence.

PFAS, however, are persistent, capable of long-distance migration, bioaccumulative, and biotoxic, posing long-term adverse effects on environmental organisms and human health. They can persist in the environment, are almost not biodegraded, and once entering the human bloodstream, they can accumulate for a long time. They are currently recognized as one of the world's most difficult-to-degrade organic pollutants, often referred to as "forever chemicals" and "toxic time bombs."

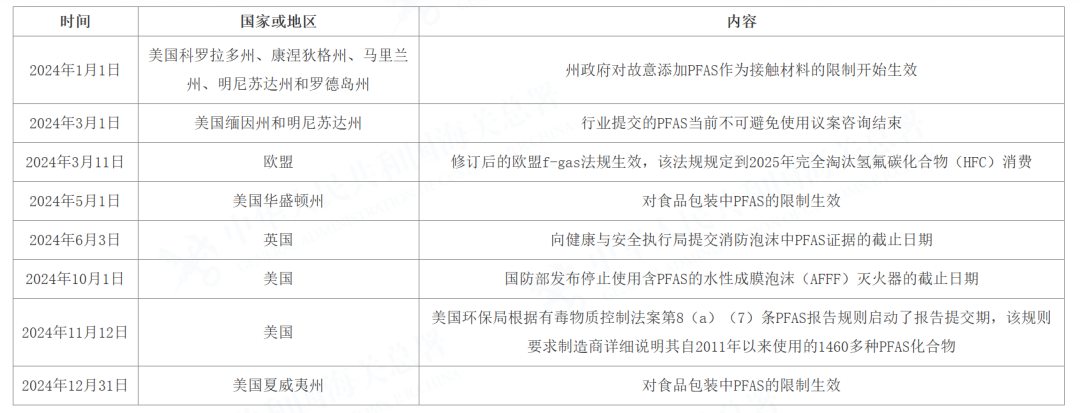

Global PFAS regulatory policies continue to escalate.

Currently, global regulations on PFAS are becoming increasingly strict, and enforcement agencies are intensifying their efforts regarding these substances. More and more PFAS compounds are being included or are about to be included in regulatory controls.

Source: Beijing Customs

In April this year, the U.S. Environmental Protection Agency issued new regulations, implementing more than 20 measures to strengthen PFAS control, including imposing stricter limits on the content of PFAS in drinking water.

In China, the current standard for drinking water adopts GB/T 5750.8-2023 "Standard Examination Methods for Drinking Water Part 8: Organic Indicators," which imposes limits on 11 types of PFAS, including PFOA and PFOS.

In 2023, China has classified certain PFAS chemicals as persistent organic pollutants (POPs) and included them in the "List of Key Controlled New Pollutants (2023 Edition)," prohibiting their production and processing use (except for exempted purposes). Additionally, the current national food safety standards in China have not approved any PFAS substances for use in the production of food contact materials.

In this context, international chemical giants such as 3M, DuPont, Chemours, Solvay, and BYK have announced plans to gradually reduce the production of PFAS-related products and shift towards high-performance chemical alternatives.

For example, Solvay will cease the production of TFA and its fluorinated derivatives (classified as PFAS) at its Salindres plant in France in September 2024; BYK-Chemie will stop producing additive products containing PFAS in August 2024.

Notably, PFAS occupies an irreplaceable position in many high-performance material fields due to its excellent stability, water resistance, oil resistance, and low friction properties. Taking semiconductor etching liquid as an example, PFAS can precisely control the etching process to ensure the high precision requirements of chip manufacturing. In contrast, its alternatives have significant shortcomings in terms of purity and stability, resulting in a decreased yield of chips. If companies adopt alternatives, costs are expected to increase by 20% to 50%.

In the fuel cells of new energy vehicles, PFAS serves as a key component, significantly enhancing the performance and stability of the cells. However, so far, it has been difficult to find materials that can completely replace PFAS in this application scenario. Additionally, PFAS has deeply integrated into various sectors of the industry chain, appearing in textiles, surfactants, food packaging, non-stick coatings, fire-fighting foams, and more. The supply chain has developed a strong dependency on PFAS, and the process of replacement, from research and testing to large-scale production, typically takes 5-10 years. This means that a comprehensive replacement of PFAS in the short term is challenging to achieve.

Sources: Reuters, DuPont, Chemical New Materials, and other publicly available online information

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track