Say No to Repeated Mold Modification! Sukeli® Launches DuoJin™ Spray-Free Metallic Finish

Over the years, plastics have also given their all to stand on a higher stage.

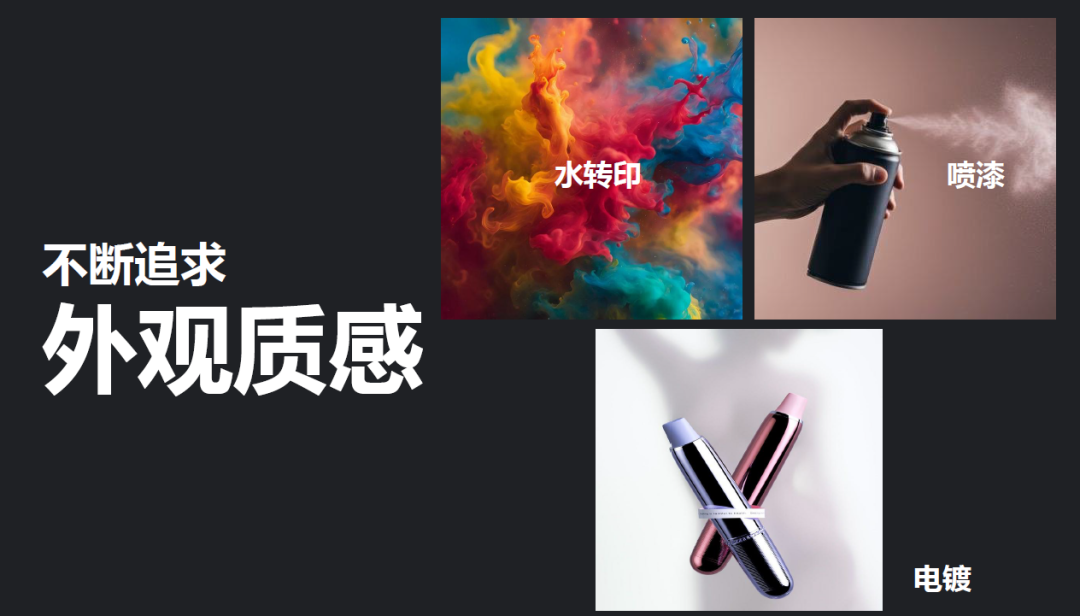

△ To make the appearance texture more stunning!

From basic painting to intricate water transfer printing, and finally to the dazzling Bling Bling electroplating... Each upgrade enhances the texture towards being more advanced and more realistic, enough to rival more expensive materials.

△ In order to make processing more efficient and convenient!

In-mold decoration (IMD), vacuum coating (PVD), and two-color injection molding—these cutting-edge technologies have emerged one after another, firmly maintaining high aesthetics while completing complex processes in one step, pushing processing efficiency to new heights.

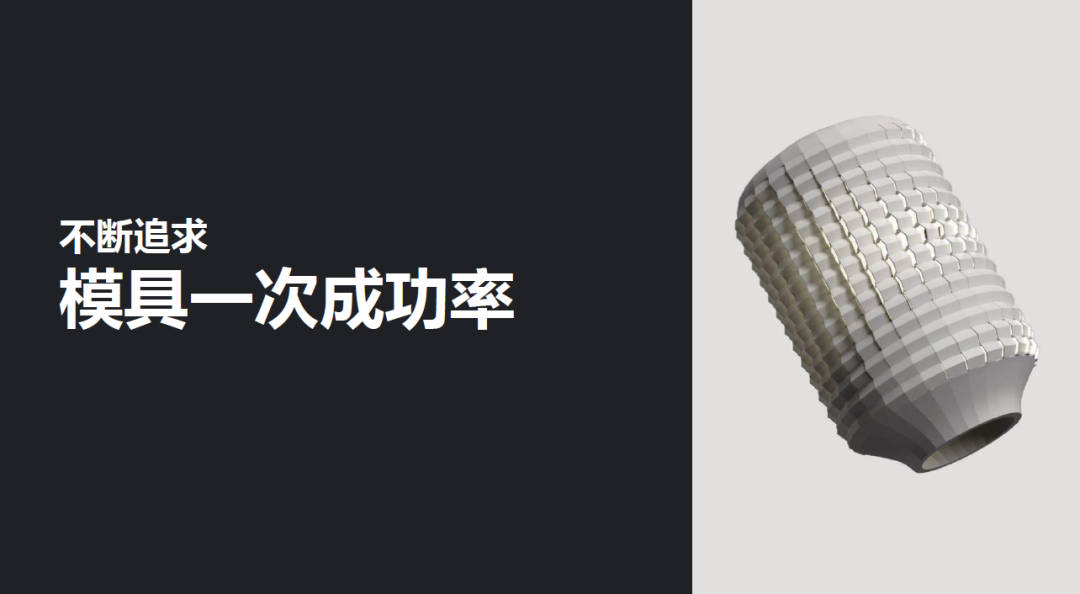

△ In order to achieve a higher success rate for one-time injection molding.

We have completely bid farewell to the old mode of mold-making that involved huge investments, complicated processes, and often unsatisfactory yield rates.

It has gradually shifted to the current approach, starting with precise early-stage mold flow analysis and rigorous DFM reviews, followed by direct experimental mold validation. Every step is meticulously planned to avoid the agony of repeated modifications later on, minimizing trial-and-error costs and striving for "the first mold to be the final product."

Of course, if you want your product to simultaneously achieve "better texture, more convenient processability, and a higher success rate of one-time molding," the traditional approach is:

You have to go to great lengths to find a matching mold factory, suitable processing techniques, and reliable surface treatment technology — going around in circles, consuming time and effort, with costs remaining high.

One word: exhausting!

Today, in the field of metal appearance, we bring you a product that is enough to rewrite the rules of the game.

It doesn't require you to travel around, spend months or even years, and there is no need to invest a huge cost to trial and error.

It is the ultimate solution that perfectly combines "texture, ease of processing, and one-time injection molding success rate," freeing you from the headache of coordinating all parties.Gold-winning™ no-spray metal effect.

Are you ready? This time, we will make achieving a plastic metallic appearance simpler than ever before.

Some people may question why the "Gold Medal™ Spray-Free Metallic Effect Solution" can make such bold claims.

Today, let's skip the lengthy discussion and speak directly with practical mass production cases.

Let's see whether it truly has strength or is just a hype wrapped in concepts.

Before that, let me keep you in suspense:

Among the following two car door trim pieces, can you guess which one is painted and which one is paint-free?

The answer may surprise you.

The part below, which has a stronger texture and more distinct patterns, is a one-time injection-molded product with a spray-free metallic effect that requires no additional post-processing.

The one above, which appears to be darker in color but lacks strong texture and grain, is actually a sprayed product that has undergone countless post-processing treatments.

So, does painted always have a better appearance and texture than non-painted?

It turns out that being too stereotypical will only get you slapped in the face. ☺

When it comes to textured metallic appearance parts, what painting can achieve, paint-free can also achieve; what painting cannot achieve, paint-free also cannot achieve!

Certainly, as the ease of use of spray-free metallic effects becomes more widespread in the market, questions have also begun to surge in this direction:

For example,

Everyone is using metallic effects—how can I create differentiation?

Everyone wants to use spray-free metallic effects, but it's difficult to solve the defect issues.

While others have already upgraded and iterated several versions of the metallic effect, I'm still stuck on the basic version "spinning around."

...

Therefore, in response to these questions, the Kumho Sunny Plucoly® Division has tailor-made two major versions of the Duojin™ spray-free metallic effect for everyone.

A more user-friendly version that can be quickly implemented.

An upgraded version with a stronger metallic appearance and texture.

What are the differences between these two versions? How should you choose? Which one is more suitable for you?

Please see the actual case:

▶▶▶ Gold Rush™ No Spray Paint Metal Effect - Easy Version

Do you think the easy-to-use version is just a simple assembly line product?

In fact, the easy version of the Gold Medal series is not simple either.

As we all know, in non-spray metal effects, the simpler the structure, the smaller the area, and the flatter the surface, the easier it is to successfully implement. Therefore, the commonly seen non-spray metal effects on the market are mostly either 'small and delicate' or 'large and flat'.

However, for such large areas with semi-circular curves, using conventional spray-free metal effects would not only result in numerous difficult-to-resolve defects but also pose considerable challenges in implementation.

But, inThe Gold-Easy Version with an Expanded Processing WindowHere, as long as thorough mold flow analysis is conducted in the early stages, almost no further adjustments are needed, enabling one-time injection molding with virtually no flow marks or other defects.

The texture of this is comparable to the complex process of painting.

If you think this structure is still a bit too simple, then why not take a look at more complex structural components.

The most typical example can be seen in this one, a digital car grille that has won the Environmental Innovation Award.

The unique "dragon scale" shape formed in one piece, coupled with the starlight sparkle effect of Ronglin Gray, not only achieves a yield rate of up to 90% but also maintains a 100% recyclable and environmentally friendly attribute. Moreover, it successfully overcomes common injection molding defects such as tiger stripes and weld lines.

Therefore, complex three-dimensional structures may seem like a "hot potato" when it comes to processes like spraying that require multiple post-processing steps. However, with the easy-to-use version of one-time injection molding, it's a piece of cake.

Of course, the Duojin Easy-to-Use series not only ensures the product's appearance quality and processing convenience but also guarantees certain performance requirements of the product.

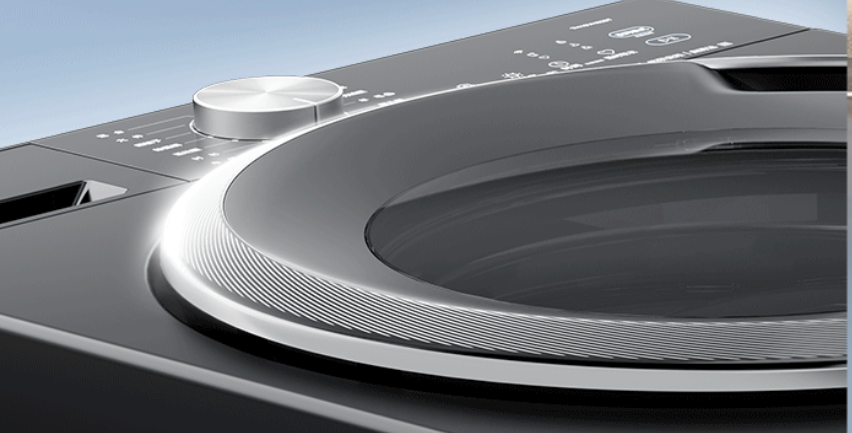

For example, the front lower casing of this large-screen television requires a certain metallic appearance and a certain level of performance strength.

And this: a trendy refrigerator’s ice bar/handle, which conforms to international design trends and requires low-temperature resistance.

So, if you are worried about the difficulty of making large items, handling curves, and balancing performance?

Or, does your own product need rapid iteration while carefully controlling costs?

You can then try the user-friendly version of Duojin™ spray-free metal.

The user-friendly version with a wider processing window is a metal effect solution without spraying that makes your ideas come to life more reliably.

Compared to processes such as spraying, which requires countless post-processing to achieve a good metallic texture, it is more worry-free, cost-effective, and hassle-free.With a simple one-shot injection molding process and no need to modify the mold, you can achieve a flow mark-free and impressively metallic appearance.

No matter how you look at it, it's a more cost-effective deal!

So, what about the upgraded version?

▶▶▶ Duojin™ Metal Effect Without Spraying - Upgraded Version

In simple terms, translate the above content into English and directly output the translation without any explanation.Gold Medal Upgrade VersionWith a more refined metallic texture, it achieves the leap from "1080P" to "2K"—this is not just a simple parameter upgrade, but a visible refinement and a tangible texture.

More importantly, it breaks the monotony of the metallic appearance.

By innovatively combining different textures, a unique and iconic appearance can be created that users will remember at a glance and even be willing to share proactively.。

In other words, the "Gold Winning Upgrade Edition" will use groundbreaking metal innovative appearance to create an inimitable brand mark for your product, establishing a distinctive differentiation from other products.Differentiation advantage in appearance。

For example,Overlay different textures of metallic effects.

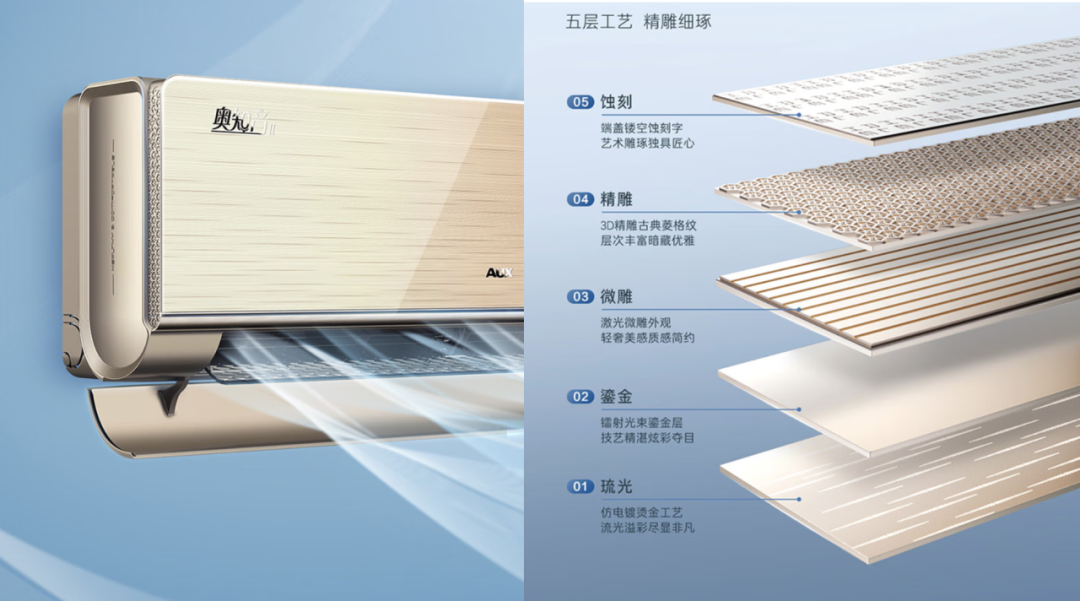

Look, this air conditioner features a gilded phoenix feather pattern with a metallic finish.Layered phoenix feather-like patterns with gilded metallic texture.

Compared to conventional non-spray metal effects, this combination of metal and texture design enhances the color gradation by at least 30%. It not only adds a palpable sense of texture rhythm but also elevates the overall appearance quality to a higher level, making it easier to stand out in a market saturated with homogeneous products.

This watch also features a metal-edged design inspired by classic timepieces.Minimalist geometric line texture + deep metallic titanium bright silver colorWith its clean lines and delicate sheen intertwined, it highlights everyday practicality while satisfying an art-like sense of refinement, combining both functionality and aesthetics.

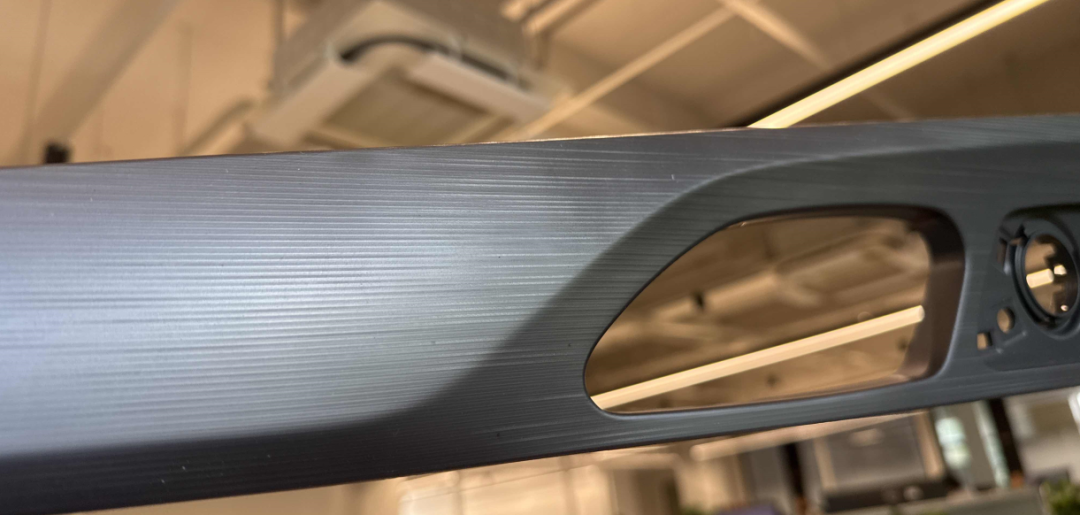

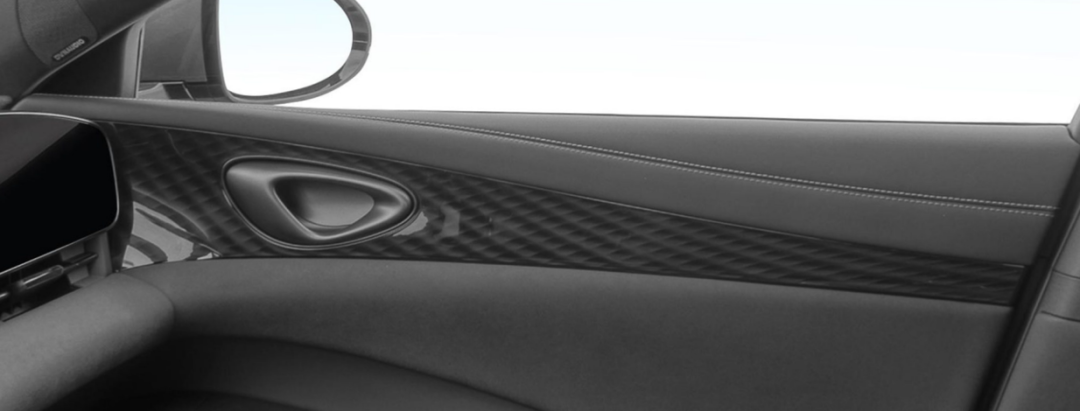

And this one, an automotive interior part with a brushed texture layered on top.

In addition, there is alsoOverlay different processes of metal effects.。

For example, this industry-first productSpray-free metallic effect + new technologyThe award-winning work is a classic example that not only achieved blockbuster aesthetics but also managed to avoid being constrained by costs.

Not only has it achieved an extraordinary breakthrough in appearance, but the same panel also displays several different textures when viewed from different angles! The cool factor is maxed out!

It has even broken barriers in cost reduction and efficiency improvement; compared to those laborious processes, it not only cuts costs by 70% directly but also triples production efficiency!

It perfectly illustrates the significance of spray-free coating—achieving great results with a small amount of money.

This one features a two-tone injection-molded design with layered and distinct textures.

Simple summary: Translate the above content into English, output the translation directly without any explanation.

Easy-to-use versionA wider processing window can help you update and iterate more quickly, allowing your ideas to be implemented steadily.

More innovative results, better helping you pursue greater differentiation in appearance design and upgraded tactile experience.

Of course, the above cases are just the tip of the iceberg.Gold Rush™ No-Spray Metal EffectAt the time of official release,

There will be more breakthrough innovations in spray-free metallic effects in the future, with customized solutions for various defect issues and practical tips to ensure efficient implementation. These will be launched successively!

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track