Satellite chemical's profits surge! can the 26.6 billion yuan high-end new materials project meet expectations? a review of progress on four major projects

Recently,Satellite ChemistryPublishedThe semi-annual performance forecast for 2025 shows an expected net profit attributable to shareholders of the listed company to be between 2.7 billion and 3.15 billion yuan, representing a year-on-year increase of 31.32% to 53.20%.。

What are the profitable secrets of satellite chemicals? What is the production capacity situation? Which projects are about to be put into operation this year? Let's take a look below.

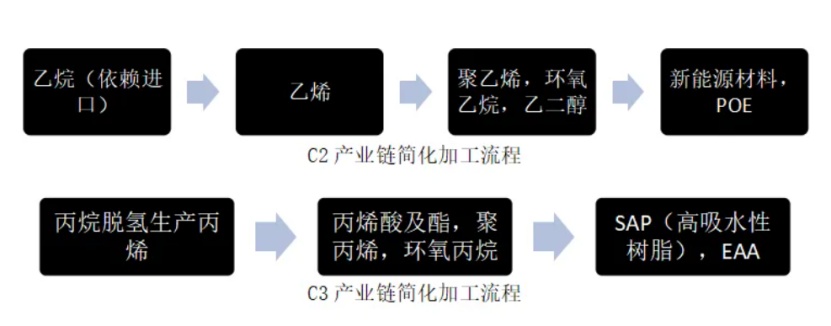

1. LayoutWhy is starting with C2/C3 so profitable?

Satellite ChemistryStarting from the C3 industrial chain (acrylic acid and esters) in 1992, and entering the C2 industrial chain (ethane cracking to produce ethylene) in 2017, the company has gradually developed into a leading domestic light hydrocarbon chemical enterprise through vertical integration expansion and technological innovation. Since 2021, it has been expanding into high-end new materials and new energy sectors.

Satellite ChemistryLong-term layout of basic chemical raw materials and derivatives, including propylene, acrylic acid and esters, ethylene glycol, ethylene oxide, polyethylene, polystyrene, polyether monomers, and superabsorbent resin.These products have mature application scenarios, covering multiple fields such as plastics, textiles, building materials, and sanitary products. The market demand is stable but highly competitive, and the profit margins are limited under traditional production models.

Star ChemistryHow to achieve thisHigh performance growthOn the one hand, there are new technologies, such asSatellite Chemicals has also developed a green, low-energy process for the efficient catalytic hydration of ethylene oxide to produce ethylene glycol, achieving a high conversion rate of ethylene oxide.More than 99.995% ethylene glycol selectivity improvement, cost per ton reduction, and annual efficiency increase of over 100 million yuan.

On the other hand, it is aimed at high-end.Overall, when olefin integration enterprises extend to the downstream of the industrial chain, the higher the technical requirements, the stronger the profitability usually is. POE, EAA, α-olefins, and other new materials belong to the high value-added sector, with technical capability being their core competitive advantage.

What is the potential for domestic substitution in high-end downstream products of C2 and C3 chains?Satellite ChemistryIndicates,Currently, the domestic industryThe structural problem of "oversupply in the low-end and shortage in the high-end" is becoming increasingly prominent.High-end polyolefin The self-sufficiency rate is only65% of high-end polyethylene and POE products are highly dependent on imports. High-end polyethylene materials have good economic benefits and extremely high technical barriers. The technical challenges of high-performance catalysts, polymerization processes, and comonomers remain key factors hindering the increase in the localization rate of high-end polyolefin materials.In the future,==Leverage the first-mover advantage fully.Promote the localization process of high-end polyolefin materials.

2. Key Satellite Chemical Projects Inventory

The key to profitability in the olefin industry chain lies in moving towards downstream segments with high technical requirements and high added value. Satellite Chemical has seized this point and laid out a series of key projects, as detailed below:

1、Total Investment266 billion yuan!High-end New Materials Project

On the morning of June 24, 2024, the domestic first α-olefin comprehensive utilization high-end new materials industrial park project (hereinafter referred to as the high-end new materials project), invested and constructed by Satellite Chemical in Xuwei New District, Lianyungang, officially commenced construction.

Total investment in the high-end new materials projectThe project, with an investment of 26.6 billion yuan, adopts independently developed high-carbon α-olefin technology to extend downstream into high-end polyolefins, polyethylene elastomers, lubricating oil base oils, ultra-high molecular weight polyethylene, and other high-end new materials.The market space is vast, and the by-product hydrogen is utilized as a resource to promote the construction of a new energy system.

The project is constructed in two phases. The situation for the first phase is investment.12.15 billion yuan, mainly for construction.Two sets of 100,000 tons/year α-olefin (LAO) units, one 900,000 tons/year polyethylene unit (45×2) #3, one 450,000 tons/year polyethylene unit #5, one 120,000 tons/year butadiene extraction unit #2, one 260,000 tons/year aromatics processing integrated unit, and supporting 2,000,000 tons/year raw material processing unit #3 (including WAO supporting unit).Warehousing,LNG storage tanks, auxiliary facilities, and off-site pipelines projects.

Phase II main construction3 sets of 100,000 tons/year alpha-olefin (LAO) units, 3 sets of 200,000 tons/year polyolefin elastomer (POE) units, 1 set of 30,000 tons/year polyalpha-olefin (PAO) unit, 1 set of 350,000 tons/year poly** unit.#and supporting 2 million tons/Year Raw Material Processing Unit 4#Warehousing, auxiliary facilities, off-site pipelines, and other projects.

Regarding Recent Developments!On July 16th, the environmental impact assessment for the polyethylene elastomer industrial pilot plant project of Lianyungang Petrochemical Co., Ltd. was accepted! The project involves an investment of 140 million yuan to construct a polyethylene elastomer industrial pilot plant, building a new set of industrial pilot facilities capable of producing 500 tons per year of C4 polyethylene elastomer or 600 tons per year of C8 polyethylene elastomer.

2. Investment3 billion!Satellite ChemistryEnhance high performanceCatalyst

The year 2025On June 20th, Satellite Chemical announced at a major project signing ceremony held in the Nanhu District of Jiaxing that it will invest 3 billion yuan to construct high-performance catalytic...New MaterialsThis strategic layout marks a crucial step for the company in its transition towards becoming a low-carbon chemical new materials technology enterprise.

The project will focus on creating an industrial platform that integrates the research, production, and application of catalysts, covering ethylene production.High-end products such as α-olefin catalysts and polyolefin elastomer catalysts are considered core technologies in the chemical industry chain. Breakthroughs in high-performance catalysts will strongly support Satellite Chemical's development in the four strategic areas of new energy materials and new polymer materials.

In recent years, Satellite Chemical has continuously increased its investment in research and development, achieving significant breakthroughs in several catalyst fields. Its independently developed ethylene production...Both 1-octene catalysts and POE catalysts have been industrially validated, achieving an advanced international level of technology. The company currently holds over 500 global patents, with catalyst-related patents accounting for 20%.

3、Total Investment 440 million yuan!A 90,000-ton acrylic acid and 100,000-ton refined acrylic acid project.

On January 6, 2025, Satellite Chemical commenced the construction of a project in Nanhu District, Jiaxing, with an annual production capacity of 90,000 tons of acrylic acid and 100,000 tons of refined acrylic acid, with a total investment of 440 million yuan. The project covers an area of 38,000 square meters and is expected to generate an additional annual output value of 1.36 billion yuan and tax revenue of 195 million yuan after it becomes operational.

Currently, the satellite chemical company contracted by China Chemical Equipment Technology Co., Ltd.The tower heat exchanger (crystallizer) for the expansion project of 90,000 tons/year of acrylic acid and 100,000 tons/year of refined acrylic acid has been successfully shipped. It is mainly used for purifying general acrylic acid into high-purity acrylic acid and processing super absorbent polymer (SAP), thus laying a solid foundation for raw materials in the high-end resin layout.

Investment of 1.2 billion yuan!300,000-ton Super Absorbent Polymer (SAP) Project

The year 2025January 18th,Satellite ChemistryOfficially sign the annual production at the headquarters.The 300,000-ton Super Absorbent Polymer (SAP) project was personally chaired by Chairman Yang Weidong. The total investment for this project is 1.2 billion yuan, and it will involve the construction of a 56,000 square meter production base. Once completed, it will become a significant part of the domestic SAP production capacity layout.

Superabsorbent resin(SAP)It is a hydrophilic polymer compound with a loosely cross-linked network structure. Over 90% of SAP is used in the hygiene products field (among which baby diapers account for approximately 70%, adult incontinence products account for approximately 17%, and feminine hygiene products account for approximately 9%).

3. Can the progress towards high-end transformation live up to expectations?

Satellite ChemistryHow far can we go on the path of high-end and domestic development? The key lies in two aspects.。

1、Stability of core material supplyHow to ensure?

Satellite Chemical's core response to the scenario where "other countries globally are planning ethane feedstock process production lines and in the next two to three years, U.S. ethane may be consumed by more countries" lies in building a raw material supply barrier based on its existing unique advantages. The company, through joint ventures with suppliers, owns proprietary ethane pipelines and export facilities and has established a mature ethane shipping fleet. These supporting conditions, in the current global context of insufficient ethane pipelines and export facilities and a scarcity of specialized shipping vessels, become its unique competitive advantage. This ensures a stable supply of ethane feedstock, providing critical support for the continuous advancement of high-end, domestic projects, and allows the company to maintain its footing amidst potential challenges of raw material constraints.

2、 Can POE, which is highly dependent on imports, turn the situation around?

While ensuring a stable supply of ethane feedstock and laying a solid foundation for high-end and domestic production, Satellite Chemical also demonstrates strong capabilities in breaking the dependency on imported key materials, especially in The field, which is highly dependent on imports, has significant advantages.

As the core material for photovoltaic encapsulation films, POE is in high demand in fields such as photovoltaics and new energy vehicles due to its excellent electrical insulation, aging resistance, and high and low-temperature performance. However, the domestic market has long been highly dependent on imports. Satellite Chemical, through the independent development of high-selectivity ethylene tetramerization technology to produce high-purity 1-octene, has successfully overcome the raw material bottleneck in POE production. This technology has high barriers and provides core support for the localization of POE.

Satellite Chemical stated that the company The industrialization of the POE project is steadily progressing, with plans to commence production as soon as possible. This will not only effectively alleviate the current reliance on imports for POE in the domestic market but also enable the company to leverage its technological advantages and industrial chain synergy to gain a foothold in this high-potential market. This further solidifies its leading position in the localization of high-end new materials.

Sources: Huizheng Consulting, Polyolefin People, International Financial News, Chemical New Materials

【Copyright and Disclaimer】This article is the property of PlastMatch. For business cooperation, media interviews, article reprints, or suggestions, please call the PlastMatch customer service hotline at +86-18030158354 or via email at service@zhuansushijie.com. The information and data provided by PlastMatch are for reference only and do not constitute direct advice for client decision-making. Any decisions made by clients based on such information and data, and all resulting direct or indirect losses and legal consequences, shall be borne by the clients themselves and are unrelated to PlastMatch. Unauthorized reprinting is strictly prohibited.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track