SABIC Launches MEGAMOLDING™ Platform to Enable Large Thermoplastic Components Across Multiple Industries

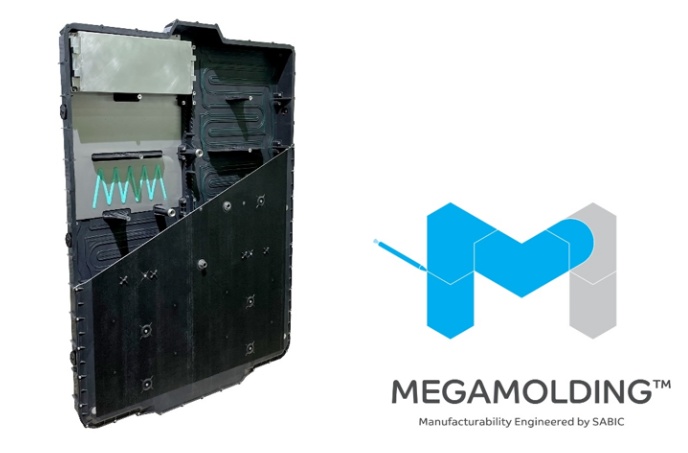

SABIC's MEGAMOLDING™ platform enables more efficient manufacturability of large high-performance thermoplastic components.

By overcoming traditional cost pressures and processing obstacles, MEGAMOLDING can offer manufacturers a scalable alternative to metal and thermoset materials.

By leveraging SABIC's expertise in materials, tool design, and process optimization, MEGAMOLDING can reduce costs and provide more sustainable manufacturing solutions.

Global chemical industry leader SABIC has launched the MEGAMOLDING™ innovation platform, aimed at enabling the manufacturability of large thermoplastic parts across multiple industries. By combining the company's deep material science expertise with the processing, tooling, and equipment expertise of value chain partners, MEGAMOLDING can achieve faster, more cost-effective, and more sustainable manufacturing solutions, superior to traditional metal and thermoset material methods.

Sami Al-Osaimi, Executive Vice President of SABIC's Polymers Business Unit, stated: "SABIC has accumulated decades of successful experience in material innovation, giving us a unique advantage to collaborate with industry partners along the value chain to redefine the manufacturing possibilities of large components with thermoplastics. Unlocking the full potential of manufacturers is significant, as it helps them enhance performance, efficiency, and sustainability."

Although thermoplastics have been used in manufacturing for a long time, their application in large components has been limited by cost, complexity, and processing challenges. MEGAMOLDING overcomes these obstacles by providing scalable, high-performance solutions that help various industries enhance design freedom and efficiency.

The innovative MEGAMOLDING platform leverages SABIC's unique expertise in advanced materials, as well as the mechanical, mold, and tooling design and processing technologies of value chain partners, making thermoplastic molding of large components applicable to more parts. The advantages of this platform include:

Adopted competitive tools, integrated components, and simplified manufacturing, post-processing, and assembly steps to improve cost-effectiveness and process efficiency.

Compared to metal casting or thermoset processing, the injection molding cycle is shortened.

- Increased design freedom enables the realization of more complex geometries and functional integration that are difficult to achieve with metal stamping or casting.

- Simplified the product architecture and improved the design for easier disassembly, sorting, and recycling.

▪ Reduced weight while still meeting strength and stiffness requirements.

Increased processing efficiency and reduced the weight of finished products, thereby lowering carbon emissions.

MEGAMOLDING is applicable to a wide range of industries and applications, including:

- Automotive — large battery enclosures (covers and trays), heavy-duty truck components (engine hoods, panels, roofs, body panels), large structural components, truck cargo platforms, etc.

▪ Energy and infrastructure — large energy storage system enclosures, wind turbine components, and grid structures.

▪ Industrial equipment — solutions for heavy machinery casings, chemical storage tanks, and pipelines.

- Consumer goods and electronics - appliance enclosures, furniture, and protective cases.

- Building and Construction - Structural panels, roofing components, and reinforced plastic solutions.

SABIC's MEGAMOLDING™ platform has achieved a breakthrough in manufacturing by enabling the scalable and cost-effective production of large, lightweight thermoplastic components, thereby helping multiple industries enhance their sustainability and performance.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track