Reviewing The Highest Profit Engineering Plastics Currently Available

Engineering plastics are widely used in high-precision fields such as automotive, electronics, and aerospace due to their excellent mechanical properties, heat resistance, and chemical stability. Some varieties, due to high technical barriers and strong market demand, have a high profit margin.

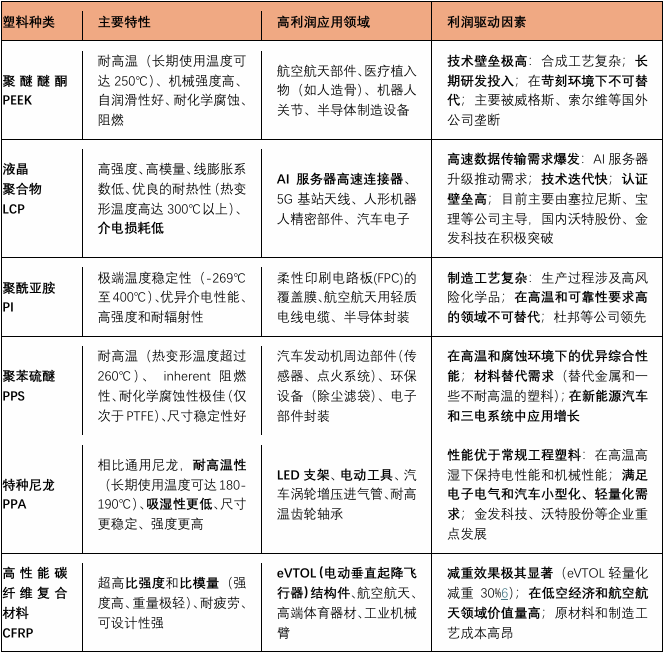

The following table summarizes several types of engineering plastics with high current profits, along with their main characteristics and application areas:

Application Expansion and Market Driven

The high-profit engineering plastics mentioned in the table have a continuously growing market demand mainly due to the following trends:

AI and High-Performance Computing: Application of LCP Materials in High-Speed Connectors for AI Servers.

New Energy and Electric Vehicles: The increased use of PPS and specialty nylon (PPA) in automotive electrification, battery management systems, and motors.

The development of eVTOL (electric vertical take-off and landing vehicles) in the low-altitude economy and aerospace sector presents vast opportunities for PEEK and high-performance carbon fiber composites (CFRP).

Humanoid robots and advanced manufacturing: PEEK, LCP, and carbon fiber composites, due to their high strength, lightweight properties, and fatigue resistance, have become ideal choices for robot joints, skeletons, and precision components.

Environmental Protection and Sustainable Development: Although some products based on bio-degradable plastics (such as PBS, PLA) may currently have a negative gross profit margin, their long-term market potential is promising as technology matures, costs decrease, and plastic bans are implemented.

How to choose high-profit engineering plastics

Choosing high-profit engineering plastics is not simply about looking at the material itself; it requires a comprehensive evaluation method.

Focus on technological barriers and domestic substitution: Generally speaking, the higher the technical threshold and the lower the domestic substitution rate of a material, the greater its profit potential may be. Pay attention to domestic companies and products that have made breakthroughs in technology and are achieving import substitution.

Focusing on high-growth downstream sectors: The profitability of materials ultimately depends on downstream applications. Currently, fields such as AI servers, humanoid robots, low-altitude economy (eVTOL), solid-state batteries, and high-end medical devices are on the verge of an explosion or in a period of rapid growth. Engineering plastic companies that provide key materials for these fields have a better chance of achieving high profits.

Examining a company's integration and innovation capabilities: Enterprises with "monomer synthesis-modification processing" integration capabilities can better control cost and quality. Meanwhile, continuous high-intensity R&D investment and the ability to innovate applications in line with customer needs are also crucial.

Understanding certification barriers: In high-end application fields, the material certification cycle is long, and the standards are stringent (such as in automotive, aerospace, and medical industries). Once integrated into the supply chain, it creates strong customer loyalty, which is one of the guarantees of high profit.

Summary

PEEK, LCP, PI, PPS, specialty nylon (PPA), and high-performance carbon fiber composites have become the "profit high ground" in current engineering plastics due to their high technical barriers, complex production processes, and irreplaceable or excellent performance in key emerging fields.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track