Researchers Develop Self-Healing and Antimicrobial Plant-Based Polymers

From medicine to electronics and optics, the new materials developed by scientists at Kaunas University of Technology (KTU) can be applied in various fields where cleanliness, precision, and durability are crucial. They stand out not only for their functionality but also for their sustainability: they are made from renewable raw materials and do not use solvents in the production process.

This new invention—a polymer developed by researchers at KTU—belongs to the category of glass trimers, a relatively new type of polymer that was discovered about thirty years ago and was only named glass trimers 15 years ago. This makes it a rapidly developing field of research, attracting increasing attention from scientists around the world.

No additives needed, making it more environmentally friendly.

According to Ostrauskaitė, so far, most glass trimers have been derived from petroleum resources and require catalysts for processing.

“Advanced materials are not only functional but also friendly to humans and the environment. This work paves the way for technologies that contribute to safer and more sustainable daily living."Professor Jolita Ostrauskaitė from the Department of Polymer Chemistry and Technology at KTU said."

“Our developed polymers are unique because they are made from plant-based compounds, cure under ultraviolet or visible light, and do not require catalysts for processing. This occurs naturally due to the chemical structure of the material itself.This scientist emphasized.

This is very important, not only because it simplifies technical processes, but also for sustainability—catalysts are often expensive, sourced from non-renewable resources, and can even be toxic. By eliminating them, material consumption can be reduced, no additional additives are required, and the technology becomes simpler, safer, and more environmentally friendly.

“Vitrimers are thermosetting polymers that, due to dynamic covalent bonds, can be processed or remolded like thermoplastics. At certain temperatures, they can self-heal after being damaged and retain temporary shapes that can be recovered later—this is known as thermally induced shape memory.,"Professor Ostrauskaitė explained.

These materials were developed and studied by researchers from the Department of Polymer Chemistry and Technology at KTU: PhD student Viltė Šereikaitė, Dr. Aukse Navaruckienė, and Dr. Sigita Grauželienė.

Polymers with this characteristic are considered smart materials, opening up new possibilities for advanced high-tech applications.

KTU scientists pointed out that the most important scientific achievement is the combination of plant-based origin, radiation-induced polymerization, self-healing ability, shape memory, antibacterial effect, and suitability for optical 3D printing in a single material.

“This kind of multifunctional and sustainable solution is still very rare, which makes it an important step forward in both science and industry.,"said the KTU researcher.

Suitable for optical 3D printing.

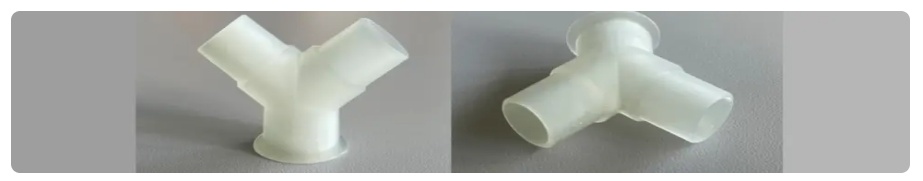

One of the most notable achievements of KTU researchers is the development of polymers suitable for optical 3D printing, which can be carried out at room temperature, consume less energy, and produce less waste. When exposed to ultraviolet or visible light, these polymers can be printed into complex shapes, such as medical device connectors.

“We successfully printed a Y-shaped connector—a typical medical component used to connect tubes in infusion or respiratory devices. This part requires high precision, making it an excellent test for the material we developed.,"the professor explained.

Optical 3D printing technology also allows for the production of other complex components, such as optical lenses or electronic parts, which require extremely precise dimensions and geometries. In addition, the material can be shaped into temporary structures that can later be modified or repaired—an invaluable advantage for prototyping and rapid response to industrial demands.

Another important innovation is the antibacterial properties of the polymer, which are generated by the structural fragments in its composition.

“The initial compounds used in the study are obtained from by-products of vegetable oil and biodiesel production. Certain fragments can interfere with bacteria and other microorganisms, disrupting their vital functions. This is why such materials can be used to manufacture surfaces or products that must remain clean and hygienic, for example, in medical devices, electronic products, sensors, or other items where microbial control is crucial.KTU scientists explained.

The experimental results show that the material effectively inhibits standard microorganisms and other common microorganisms.

This research is part of the project numbered S-MIP-23-52 funded by the Lithuanian Research Council, focusing on antimicrobial shape-memory photopolymers based on plant-based materials, conducted in collaboration with scientists from the National Research Institute Natural Research Centre, JSC 3D Creative, and partners from the University of Upper Alsace in France and Centria University of Applied Sciences in Finland.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track