Research Progress on Environmental Degradation and Impact of Biodegradable PlasticsEast China Normal University in Science Bulletin

Since the invention of synthetic plastics, more than 10 billion tons of plastic products have been produced and used.Since plastics generally have stable molecular structures, their natural mineralization process is slow, leading to continuous accumulation in the environment. This has caused irreversible impacts on the material cycles of nature, ecosystems, and social life. China has always attached great importance to environmental protection and has been committed to addressing plastic pollution. The policies to tackle plastic pollution have evolved from..."Restricting thin plastics," "limiting plastics" to "banning plastics"Advance step by step, and propose three main tasks: source reduction, recycling and disposal, and cleanup and remediation.

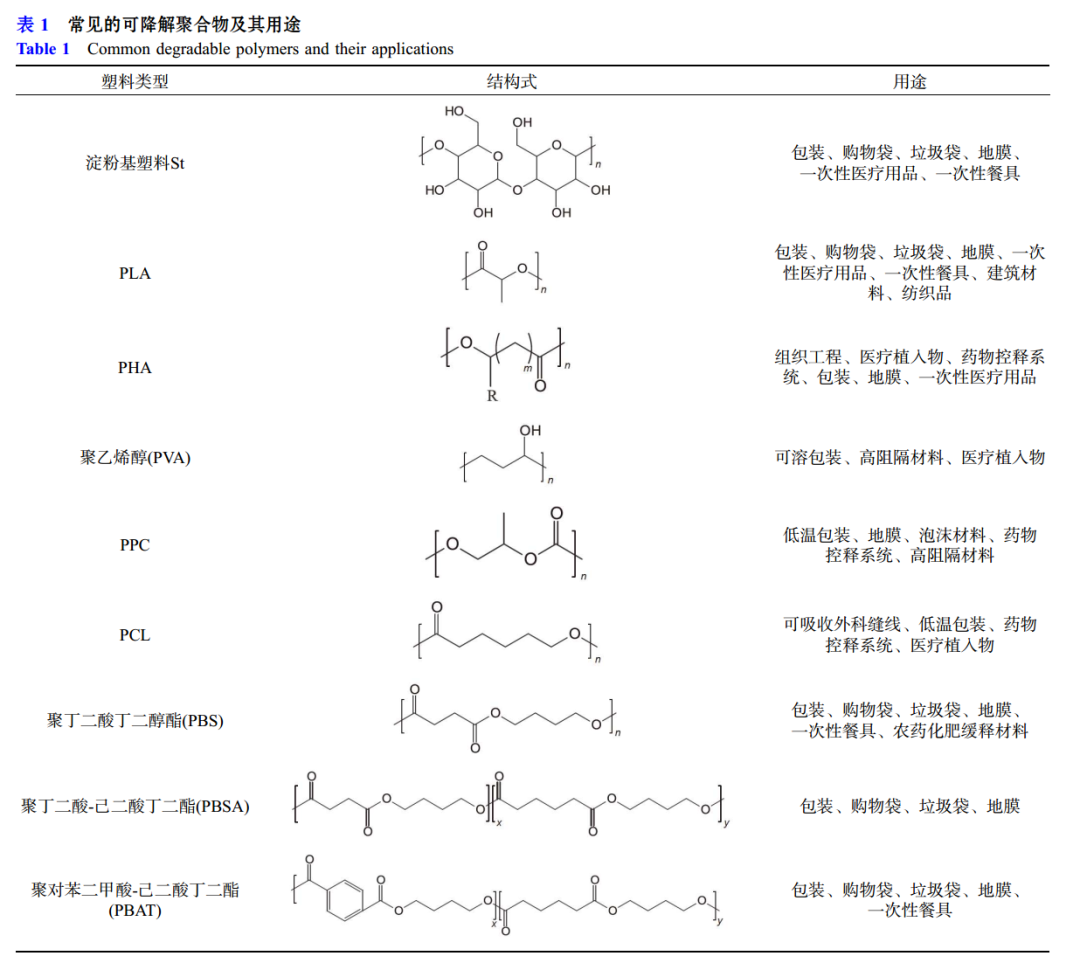

Degradable plastics (DPs)As alternatives to traditional plastics, DPs have been widely applied. DPs refer to plastics that, under specific environmental conditions and after a certain period involving one or more steps, undergo significant structural changes resulting in the loss of certain properties and fragmentation. For the assessment of plastic degradability, national standards in China (GB), the International Organization for Standardization (ISO), the American Society for Testing and Materials (ASTM), and the Organisation for Economic Co-operation and Development (OECD) have established identification criteria under various specific conditions including aquatic environments, soil environments, sludge digestion, and composting. However, the degradation of DPs is limited by environmental and temporal conditions and should not be misunderstood as being degradable under any conditions without causing any harm. Plastics that do not meet the degradability requirements specified in any of the above standards are considered nondegradable plastics (NDPs). Furthermore, the environmental impacts caused by additives, oligomers, and microplastics released during the degradation process of DPs have attracted increasing attention.

Promotion of alternatives to plastic products.The "14th Five-Year Plan for Plastic Pollution Control Action Plan" emphasizes the need for scientific and prudent promotion, carrying out research on the degradation mechanisms and influencing factors of different types of degradable plastics (DPs), and scientifically assessing their environmental safety and controllability. It also calls for improving the standards system, regulating application fields, and clarifying degradation conditions and disposal methods.DPs are mostly used in single-use plastic products, which will result in millions of tons of DPs replacing traditional plastics and entering municipal solid waste management and disposal systems each year. According to the "Classification and Marking of Municipal Solid Waste" (GB/T19095-2019), municipal solid waste is mainly divided into hazardous waste, recyclables, kitchen waste, and other waste. Based on the "Research Report on Environmental Impact Assessment and Policy Support of Degradable Plastics,"Currently, 96.77% of biodegradable plastics in China are directed towards incineration and landfill, 3.1% leak into the environment, and only 0.007% undergo biological disposal, including industrial composting (0.001%) and anaerobic digestion (0.006%).Currently, there is no consensus on how to classify and manage DPs, and incineration for harmless treatment would defeat the purpose of promoting DPs. Therefore, studying the environmental degradation behavior of DPs after disposal in different application fields is crucial for promoting the orderly development of the industry. This is an indispensable part of improving the whole-chain governance system for plastic pollution and holds significant practical importance. This article reviews the degradation and transformation characteristics of DPs in aquatic and soil environments, as well as during aerobic and anaerobic biochemical treatment of organic solid waste. It discusses how material properties affect degradation in different environments. Finally, it provides suggestions for the application and management of degradable plastics and offers perspectives on future research directions.

— 1 —

Definitions and classification related to plastic degradation

Many countries and regions have implemented or are in the process of formulating standards and regulations concerning DPs. However, the definition and classification of DPs may vary depending on commercial practices, industry standards, research fields, and even the development of the times. To avoid misunderstandings, it is necessary to clarify the definition and classification of plastics before discussing their degradation characteristics under different environmental conditions.

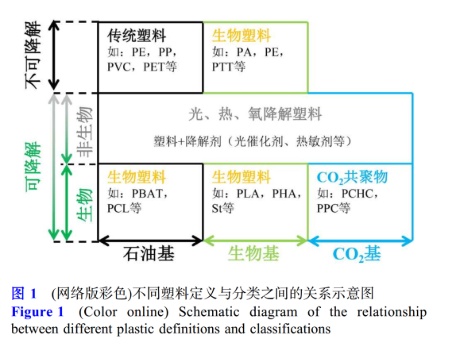

As shown, according to the source of raw materials, plastics can be divided into three categories: petroleum-based, bio-based, and carbon dioxide-based.

-

Petroleum-based plasticUsing petroleum as raw material, including non-degradable plastics (such as PE, PP, PVC, PS) and some degradable plastics (such as PBAT, PCL). This classification does not consider the type of polymer or degradation performance.

-

Bio-based plasticsDerived from renewable biomass such as cellulose, starch, PHA, lactic acid, etc. It can include biodegradable plastics (such as PLA, PHA, starch-based) and non-biodegradable plastics (such as bio-based PE, PA, PTT). In a broad sense, "bioplastics" refer to plastics that are bio-based, biodegradable, or both. In 2022, the cultivation of raw materials for bioplastics accounted for only 0.015% of global arable land, but in the future, there may be potential competition with food and feed resources.

-

Carbon dioxide-based plasticsThese mainly refer to copolymers synthesized from CO₂ and epoxides, such as PPC and PCHC, which are biodegradable. Compared to traditional polyolefins, PPC can save more than 40% of fossil energy and reduce carbon emissions. However, its heat resistance and mechanical properties are insufficient and need to be improved through modification to enhance its applicability.

1.2 Classification Based on Degradation Performance

In the vertical direction, plastics can be divided into degradable plastics (DPs) and non-degradable plastics (NDPs). Among them, DPs are further divided into abiotic degradable plastics (ADPs) and biodegradable plastics (BDPs).

-

ADPs(For example, photodegradable and thermo-oxidative degradable plastics) degrade through light, heat, and oxidation, but are mostly induced by additives and do not possess true mineralization capability. Ultimately, they may transform into microplastics, posing ecological risks. Both the EU and China have restricted their use in single-use products. Nevertheless, the characteristics of ADPs can still meet certain specific application needs and promote the development of recycling and reuse technologies.

-

BDPsPlastics that are fully biodegraded into inorganic substances such as CO₂, CH₄, and H₂O, as well as new biomass through microbial action under natural conditions, are also known as "fully biodegradable plastics." This document does not consider degradation caused by animals or plants. The mainstream BDPs currently include PBAT, PLA, and starch-based plastics, with a global production of approximately 1.136 million tons in 2023, expected to reach 4.605 million tons by 2028, accounting for over 83%.

— 2 —

Degradation characteristics of DPs under different environments

Traditional plastics are highly stable and can persist in the natural environment for hundreds of years. The accumulation of plastics in the environment has become a global environmental issue. Although strengthening the management and recycling of plastic waste, as well as implementing cleanup and remediation measures, can help reduce plastic pollution, plastics may still be released into the environment and persist in various environments through natural material cycles. When using DPs to replace traditional plastic products, the primary concern is whether their persistence time in the environment can be reduced to decrease environmental accumulation.

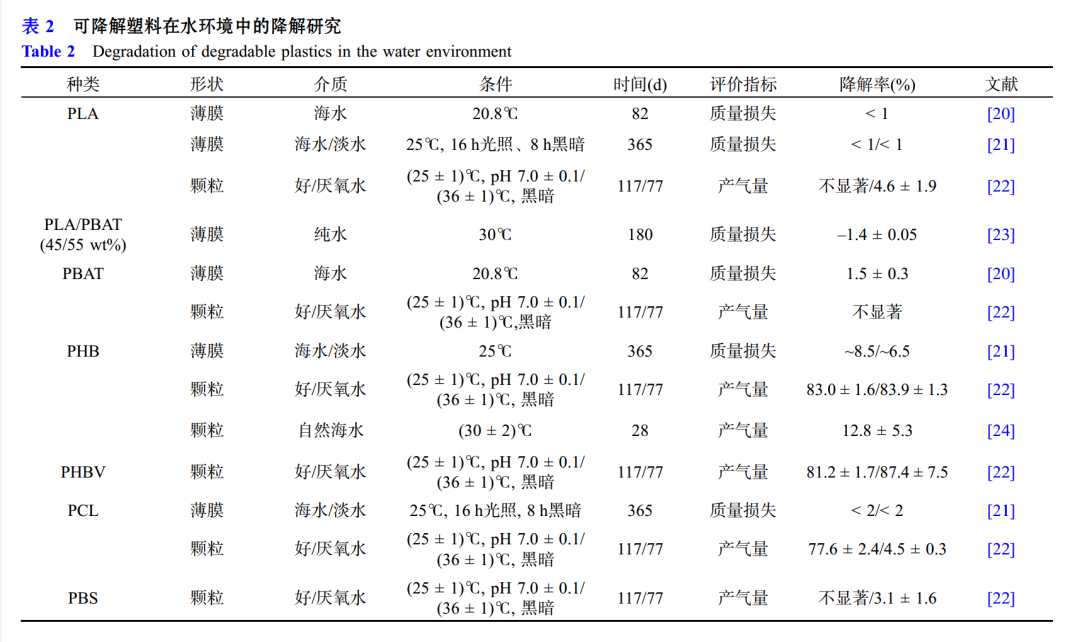

The aquatic environment plays an important role in material cycling and ecosystems, with microorganisms playing a key role in degradation. Modern molecular biology techniques, such as metagenomics, can identify microorganisms with potential degradation capabilities. For example, studies have found that members of the family Rhodospirillaceae...Pseudomonas veroniiBiodegradable PHA polyesters; other research has screened enzymes with potential to degrade PBAT from seawater (such as PETase and MHETase). However, predictions based on genomic data still require experimental validation of their actual degradation capabilities.

In the experimental simulation ( Except for a few materials such as PHB, PHBV, and PCL, most DPs (such as PBAT, PLA, PBS) degrade slowly in water environments over a short period. Current simulation experiments cannot fully reproduce abiotic factors in natural environments, such as ultraviolet radiation and water flow shear, which often work synergistically with biotic factors to accelerate degradation. Therefore, it is necessary to verify their actual degradation behavior through monitoring in real environmental settings.

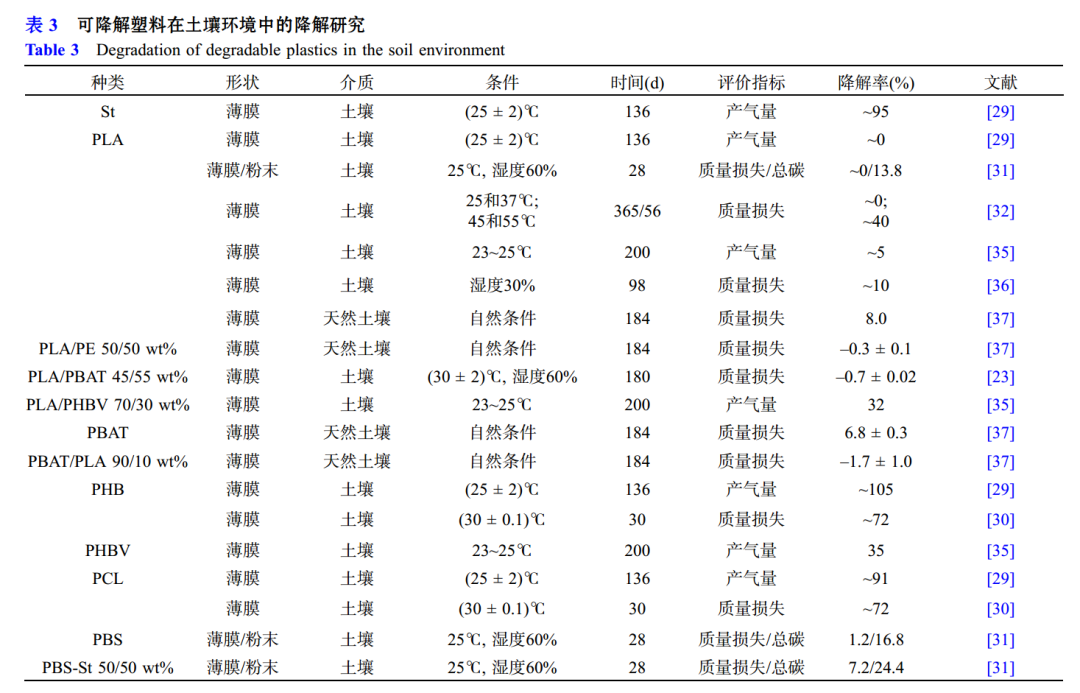

2.2 Degradation in soil environment

Plastic pollution in soil mainly originates from the residues of agricultural plastic films. DPs-based mulching films are regarded as alternatives to improve agricultural sustainability. Compared with aquatic environments, soil has weaker light exposure and oxidation, resulting in less abiotic degradation; however, the abundance of microorganisms can enhance biodegradation.

2.3 Degradation in Aerobic Composting

Since the implementation of the plastic ban in 2020, a large amount of DPs have been used for single-use packaging and have entered the urban waste management system. Although there are issues of plastic contamination in waste sorting, the co-treatment of DPs with kitchen waste can simplify the processing procedure and aligns with the direction of green development.

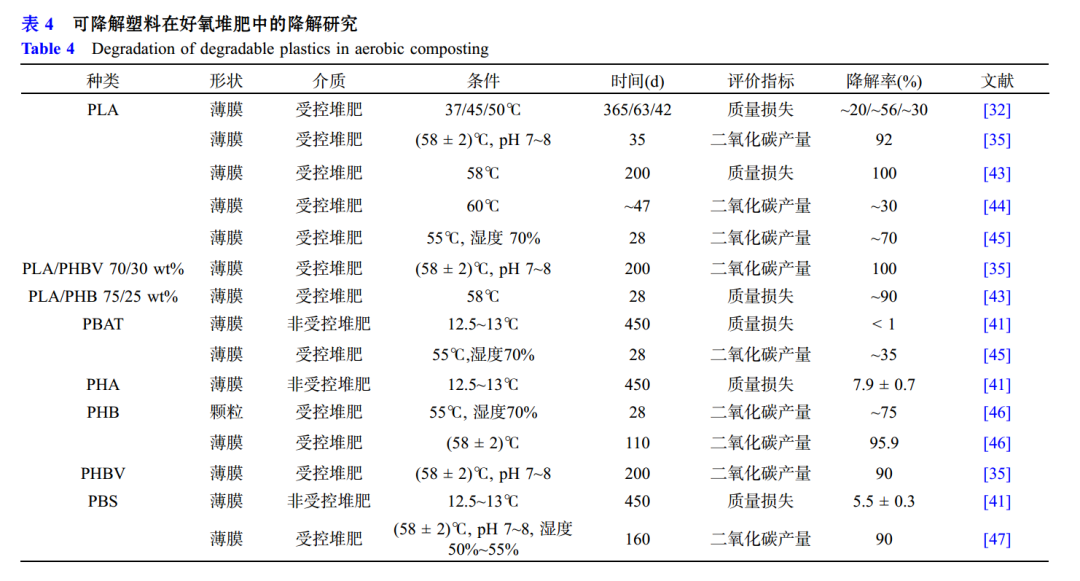

Aerobic composting (55-58°C, 180 days) can typically achieve complete degradation of DPs and serves as the standard for evaluating whether a material is a biodegradable plastic. The longer the high-temperature composting period, the more complete the degradation; for example, PLA degrades only 20% after 365 days at 37°C, while the degradation rates of PBAT and PHA are less than 10% after 450 days at low temperature (12.5°C). Composting residence times are usually only 20-40 days, which is insufficient for complete degradation of DPs and may even lead to the release of microplastics. Therefore, industrial composting is necessary to maintain high-temperature conditions to ensure thorough degradation.

2.4 Degradation in Anaerobic Digestion

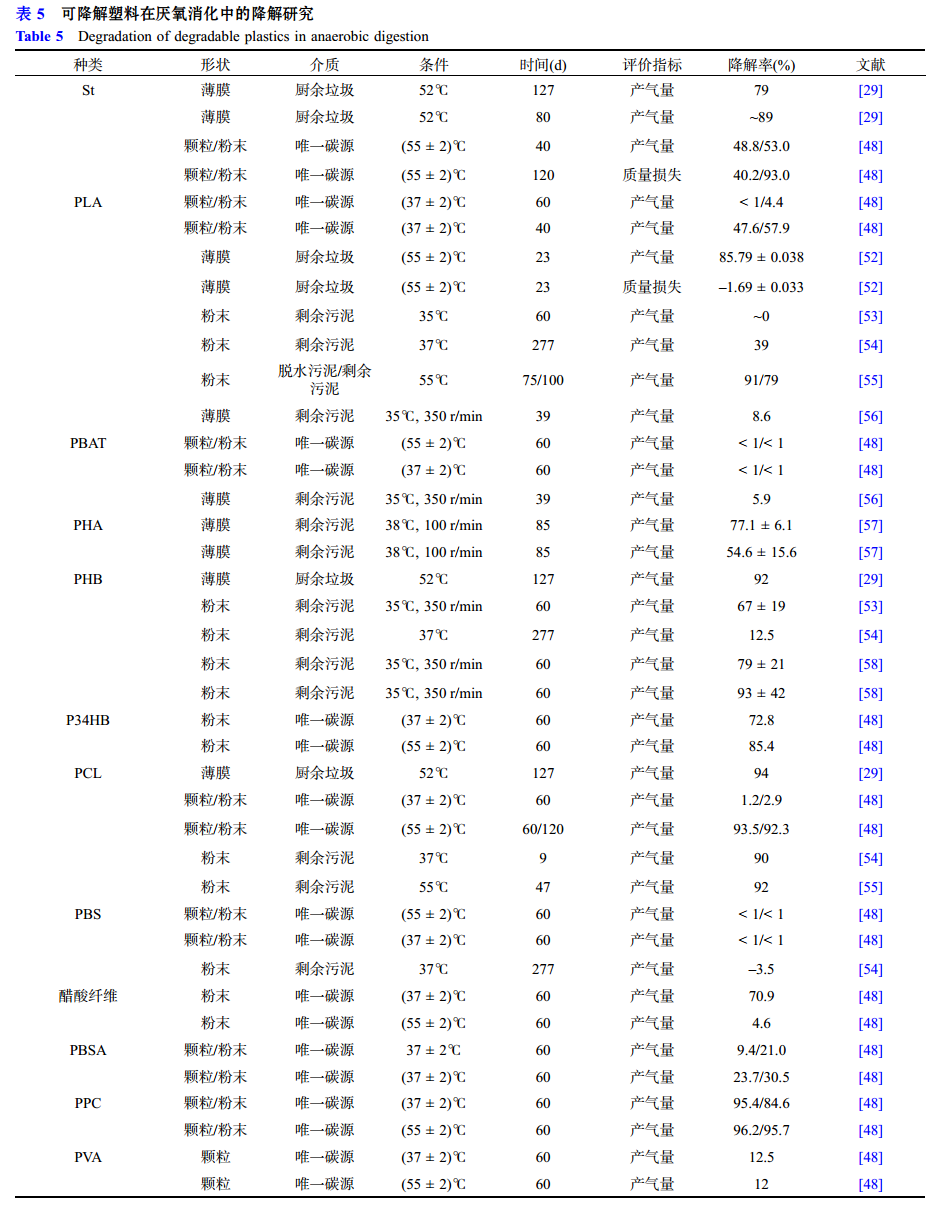

The degradation of DPs in anaerobic environments varies significantly, influenced by factors such as temperature and polymer structure. Under high-temperature conditions, most DPs have a higher degradation rate than under medium-temperature conditions. However, PBAT and PLA do not degrade significantly under conventional anaerobic conditions, and the degradation cycle of PLA even under high temperatures far exceeds 30 days. )。

To avoid the clogging and accumulation of DPs in anaerobic treatment facilities, the applicability of polymers should be determined based on their properties. Materials suitable for anaerobic environments include St, PHA, PPC, etc. In addition, their degradability under anaerobic conditions can be enhanced by adjusting blending ratios, molecular weight, crystallinity, and other factors.

— 3 —

Environmental Impact of DPs Residues

DPs have limited degradation conditions in natural environments and often exhibit a certain degree of persistence, raising environmental safety concerns. Currently, degradation tests for DPs mostly focus on their disintegration into particles smaller than 2mm, neglecting the environmental risks of microplastics. Research shows that DPs can generate a large amount of microplastics during biodegradation and enzymatic degradation processes, with toxicity comparable to that of conventional microplastics.

PBAT more easily forms microplastics in aquatic environments, and UV pre-treatment accelerates this process. PBS, PLA, and other microplastics have been detected in water samples from the Yellow River and Australian wastewater treatment plants. Although PBAT degrades rapidly during the high-temperature phase of composting, a significant amount of fragments remains during the cooling and maturation phases, with 10^3 to 10^4 microplastic particles per gram of dry compost weight.

Current detection methods still have limitations: for example, the thermal pyrolysis-gas chromatography-mass spectrometry method has a high quantification limit, traditional digestion methods can cause mass loss of DPs, and the wet sieving method is affected by sieve pores and impurities. Therefore, the accurate quantitative characterization of DPs residues in the environment still needs optimization.

Microplastics generated during the degradation of DPs can induce oxidative stress, reduce cell viability, and may adsorb pollutants, acting as carriers for them. For example, the toxicity of PHB microplastics to blue mussels is comparable to that of PE; PLA and PPC exhibit toxicity to earthworms that is not lower than that of conventional plastics. Compared with traditional microplastics, DPs microplastics have a stronger adsorption capacity for antibiotics and biocides, becoming potential pollutant concentrators. Meanwhile, antibiotic resistance genes (ARGs) are often enriched on DPs plastic particles, posing new threats to environmental health. In addition, microplastics interfere with the composting process, reduce microbial diversity, and affect the quality of humification.

The degradation of DPs releases a large amount of dissolved organic matter (DOM), some of which can be rapidly utilized by microorganisms, affecting the carbon cycle and the structure of microbial communities. Studies have found that PBAT can promote the enrichment of soil pathogens, affecting the stability of wastewater treatment systems. Meanwhile, additives released during the degradation process of DPs, such as bisphenol A and phthalates, have endocrine-disrupting effects and may enhance biofilm formation and horizontal transfer of resistance genes.

In summary, to reduce the negative environmental impact of DPs, their life cycle management should be strengthened, and degradation and mineralization should be enhanced during waste treatment to control the release of microplastics and harmful substances.

— 4 —

Summary and Outlook

Current research indicates that DPs exhibit conditional degradability in natural environments such as water and soil, as well as during aerobic composting and anaerobic digestion. This means that specific polymer types, temperature conditions, or durations are required to achieve complete degradation. Incomplete degradation of DPs can lead to the release of plasticizers and microplastics, posing certain impacts on the ecological environment. DPs are widely used as alternatives to traditional plastics, yet they are still classified and processed according to traditional plastic procedures, primarily through incineration. This approach increases economic costs without bringing significant environmental benefits. The following prospects are proposed for the promotion, application, and processing of DPs.

(1) Investigate and monitor the occurrence of DPs in real environments.Currently, laboratory-simulated controlled conditions cannot replicate the effects of abiotic factors such as seasonal changes, weathering, and water flow shear on the fragmentation and degradation of DPs. As a result, there is still a lack of systematic understanding regarding the environmental degradation and transformation of DPs, as well as the occurrence and persistence of microplastics.

(2) Formulate standards for the application scenarios and degradation capabilities of corresponding DPs.In the field of recyclability and reuse, priority should be given to recycling rather than biodegradability. For applications with high leakage risk, low reuse value, or difficulty in recycling or cleaning, disposal measures and degradation capabilities of DPs should be clearly defined based on real-world conditions. For example, standardized biodegradable garbage bags for kitchen waste can facilitate urban waste sorting.

(3) Improve the full-process management of plastic waste, and establish and optimize the classification system.To fill the gap in the classification of DPs and prevent them from being mixed with other waste for incineration. The collaborative resource treatment and disposal of DPs with kitchen waste and other urban organic solid waste is an effective measure to reduce their environmental risks and achieve a circular economy. It also aligns with the requirements of urban waste classification and green, low-carbon development.

Continue the research and development work on DPs materials.Develop corresponding materials for different application scenarios and environmental fates by blending and modifying various polymer materials to meet the needs of commercial use, mechanical properties, and degradation capabilities, thereby providing technical support for the development of the DPs industry.

(5) Strengthen research on the degradation and residual characteristics of DPs.DPs are more prone to degradation, leading to the generation of microplastics and the release of plasticizers and additives. The degradation time required for these incomplete degradation products in the environment and their impact on ecosystems still need to be further investigated.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track