Reifenhäuser is set to debut at the 2025 International Plastics and Rubber Exhibition, leading the new trend of green automated extrusion production!

The International Plastics and Rubber Exhibition is set to open on April 15, 2025, at the Shenzhen World Exhibition & Convention Center, with Reifenhäuser Group showcasing its latest technology in a grand appearance!

As a global leader in plastic extrusion equipment, Reifenhäuser is always committed to promoting sustainable and digital production, helping the plastics industry move towards a green future.

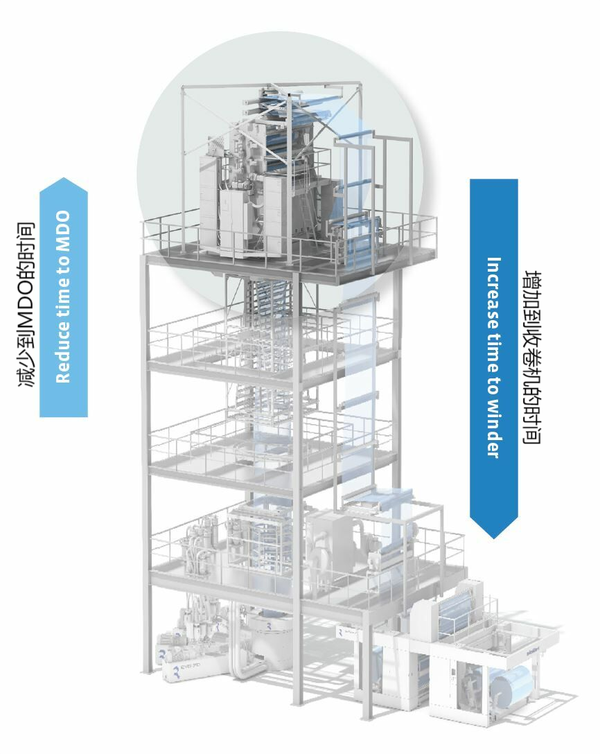

Combining suitable raw materials with Reifenhäuser's MDO ultra-stretching technology, the film is stretched directly on the upstream of the production line.

At this exhibition, Reifenhäuser will showcase its EVO Ultra Stretch MDO patented technology, helping manufacturers produce fully recyclable all-PE monomaterial films suitable for food packaging, combining high performance with environmental characteristics; at the same time, this technology can produce the world's first MDO-PE film with a thickness of only 18 micrometers, which meets or exceeds all previous market standards in terms of mechanical properties, appearance, and downstream processes.

Kdesign KARAT wind ring

In addition, Kdesign automatic air ring thickness measurement technology can improve the output of blown film production lines and reduce production costs while achieving excellent thickness tolerance and optimal film quality. The system is suitable for both new production lines and the upgrade and transformation of existing lines, capable of increasing production capacity by 25%-50%.

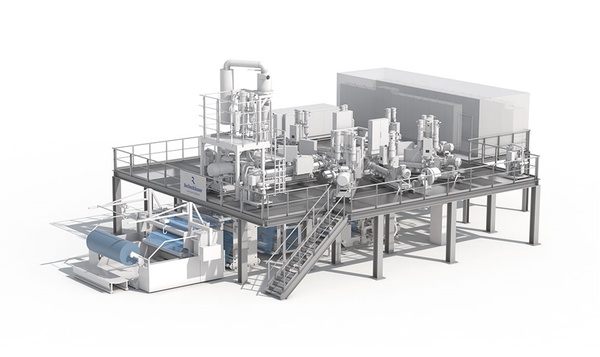

11-layer barrier cast production line

Value Cast and Value Sheet cast and sheet production lines will also be showcased. Advanced and sustainable barrier films and packaging solutions play a crucial role in reducing food loss, ensuring hygienic packaging of sensitive goods, enhancing customer convenience, and saving resources as much as possible. With our advanced, fully integrated, and automated barrier cast film production lines, we provide the film and packaging industry with safe and proven solutions. The Reifenhäuser ultra-wide cast line is a tailor-made cast film production line for special CPP and CPE films.

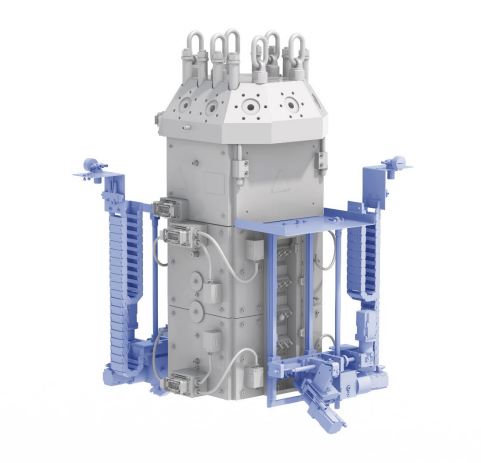

autonomous extrusion die with PAM function

Reifenhauser's autonomous extrusion die with PAM function achieves autonomous thickness control and parameter storage, ensuring high quality and consistency in repeated production. Compared to thermal expansion bolts, it significantly reduces energy consumption, shortens product changeover time, and reduces raw material waste. Fully automatic operation, no manual adjustment required, supports simultaneous multitasking, automatically adjusts die width, improving production efficiency and safety.

Booth number: 10G21, we sincerely invite you to visit and jointly explore the green future of the plastics industry!

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track