Recent Breakthroughs and Developments in the Field of Adiponitrile

Adiponitrile is a core raw material for the production of nylon 66, and its production technology has long been monopolized by foreign countries. Recently, significant breakthroughs have been made domestically in this field.

Technical Breakthroughs and Certifications

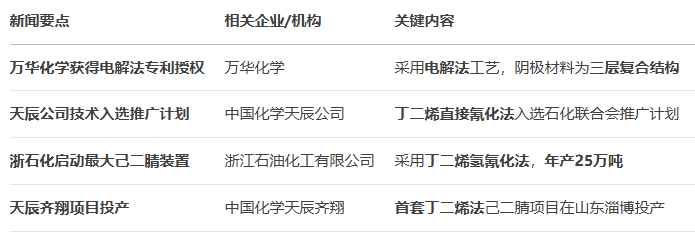

In addition to project commissioning, technological advancements and industry certifications are also important highlights in the near term.

The "Butadiene Direct Cyanation Adiponitrile Technology" independently developed by China National Chemical Tianchen Company has been successfully selected as a promotion project in the "2025 Science and Technology Guidance Plan" released by the China Petroleum and Chemical Industry Federation. This marks that the advancement and feasibility of this technology have been recognized by industry authorities, paving the way for its large-scale promotion and application.

Wanhua Chemical has taken an alternative approach with its newly acquired invention patent, which employs an electrolysis process for the preparation of adiponitrile. This process involves adding acrylonitrile, ionic liquid, and water into an electrolytic cell, where a reduction reaction at the cathode generates adiponitrile. The core innovation lies in the design of the cathode material, which features a three-layer composite structure comprising a substrate, an intermediate layer, and a surface layer, aiming to improve reaction efficiency and potentially reduce energy consumption. Wanhua Chemical defines its advantages as "green and efficient," aiming to address issues such as the complexity of current production processes, difficulties in product separation, and high safety risks.

Industry Impact and Future Outlook

Recent developments in the field of adiponitrile reflect the following trends and impacts:

1. Diversified Technological Approaches: Currently, the industrialization of adiponitrile in China is characterized by the parallel development and breakthroughs of multiple technological routes, such as direct butadiene cyanation/hydrocyanation (e.g., Tianchen, Ruizhi Group/Zhejiang Zhiying) and the electrolysis method (e.g., Wanhua Chemical). Which technology will ultimately prevail in terms of cost and efficiency remains to be tested by the market and time.

2. Breaking the Monopoly and Achieving Self-Sufficiency: Adiponitrile was once a typical “bottleneck” product in China. The successful commissioning and technological advancement of these domestic projects signify significant progress in China’s independent supply capacity of adiponitrile, which is of great importance for the security and stability of the downstream high-end material industry chain, such as nylon 66.

3. Market competition will intensify: With the planning and implementation of several large-scale projects, the domestic production capacity of adiponitrile will increase significantly in the future. Although this may lead to more intense market competition, it means more choices and lower costs for downstream users.

4. Promoting the development of high-end materials: The stable supply of adiponitrile is fundamental to the development of the nylon 66 industrial chain. Nylon 66, due to its excellent heat resistance, tensile strength, and wear resistance, is widely used in the automotive industry (especially in the lightweighting of new energy vehicles), electronics and electrical appliances, specialty apparel, and other fields. The breakthrough in domestic adiponitrile production will strongly support the development of these downstream industries.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track