Real-World Performance of Bio-Based Materials in Wearable Devices

Bio-based polymers refer to polymer materials obtained from renewable biological resources through biological or chemical synthesis. Unlike traditional petroleum-based plastics, bio-based polymers are derived from plant resources such as corn, cassava, and castor oil, offering advantages of sustainable raw materials and low-carbon environmental protection.

The main types of bio-based polymers include

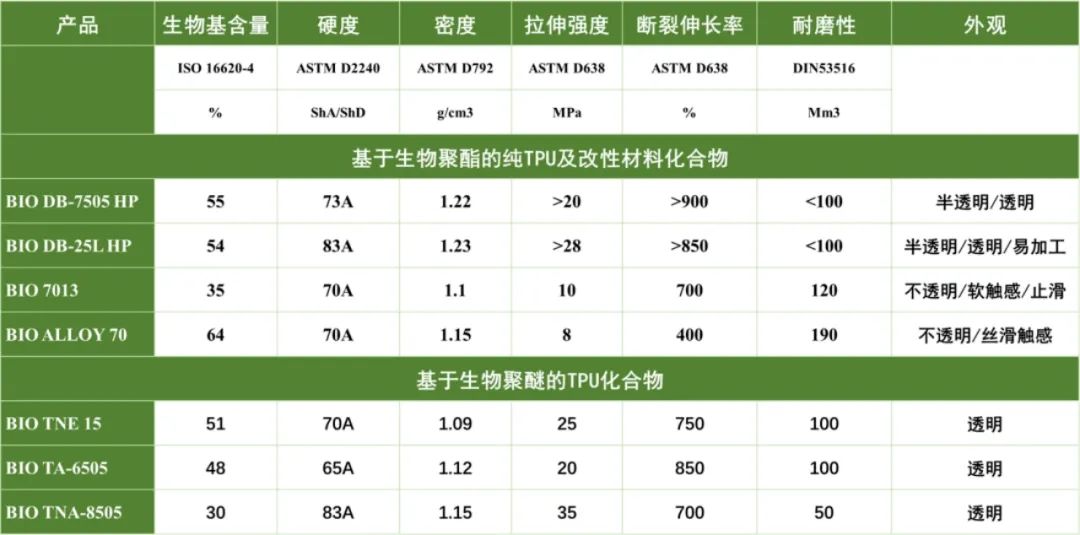

Bio-based TPU (thermoplastic polyurethane): Produced by introducing bio-based monomers during the synthesis of TPU. Bio-based TPU typically contains 30% to 60% biomass content. It possesses high strength, high elasticity, abrasion resistance, oil resistance, low temperature resistance, and aging resistance, with performance comparable to that of conventional TPU. Some manufacturers have launched bio-based TPU grades with biomass content as high as 64%, whose performance is almost on par with petrochemical-based TPU.

Performance Parameters of Some Bio-based TPU Grades from Trinseo

Bio-based PA (polyamide): Polyamide monomers are synthesized using renewable resources such as glucose or ricinoleic acid from vegetable oils, and then polymerized to obtain nylon materials. Common types include PA11, PA610, PA1010, and PA410, whose raw materials are partially or entirely derived from castor oil and other vegetable oils. Bio-based PA maintains the high strength and toughness of nylon, while offering low density and good chemical resistance. It has been used in textile fibers, automotive and electronics fields, and is also suitable for making structural components for wearable devices.

Image source: Arkema

PHA (Polyhydroxyalkanoates): A type of biopolyester produced by microbial fermentation of sugars, characterized by diverse structures and complete biodegradability. PHA can be classified into short-chain and medium to long-chain types based on chain length, with certain medium to long-chain PHAs exhibiting good flexibility. This material can naturally degrade both in vivo and in vitro, making it environmentally friendly and a candidate for materials in flexible electronic devices and wearable equipment. PHA films can be used as substrates for flexible sensors, meeting mechanical requirements while naturally degrading after disposal.

Application Potential of Straps and Casings in Wearable Devices

Straps and casings of wearable devices such as smartwatches and fitness bands need to balance comfort and durability. Some manufacturers have previously used silicone or fluororubber straps, but these materials may contain harmful substances like D4, D5 siloxanes, or PFAS, raising safety and environmental concerns. Bio-based polymers are expected to better meet various performance requirements.

Bio-based TPU watch straps: Bio-based TPU is highly suitable as a material for wearable watch straps. TPU itself offers excellent elasticity, skin-friendly comfort, and resistance to wear and hydrolysis, and the bio-based version retains these advantages. Watch straps made from bio-based TPU maintain toughness even after intense exercise and prolonged exposure to sweat, making them less prone to breaking or sticking to the skin. TPU has good biocompatibility and has been widely used in the medical field. By adding inorganic antibacterial agents to the formulation, TPU straps can be endowed with long-lasting antibacterial and deodorizing properties to prevent bacterial growth in sweat. Some manufacturers also incorporate UV absorbers to enhance the straps' resistance to ultraviolet aging.

Bio-based PA Housings: The outer shells of smartwatches and fitness bands are often made from engineering plastics or composite materials. Bio-based PA offers high mechanical strength and good thermal stability, making it a promising choice for housing materials.

Castor oil-based PA11 material, after reinforcement, can be used to manufacture watch cases with good impact resistance, temperature difference resistance, and waterproof sealing performance.

The Swiss Mondaine watches once launched a watch case made of a composite material consisting of 41% castor oil-based polymer and 30% glass powder, to achieve long-term shock resistance and waterproofing. The bio-based case has been tested to be comparable to conventional plastics in terms of thermal stability, dynamic strength, and impact resistance.

Nylon fibers made from bio-based PA can be used to weave watch straps or case ornaments, maintaining strength while reducing dependence on petroleum materials.

Huawei had already partially adopted castor oil-based PA plastic in its smartwatches, using it for components such as the back cover or the body bracket.

Exploration of PHA and Other Materials: Due to its fully biodegradable properties, PHA has attracted interest in the field of wearables. Flexible variants can be used for disposable or short-term skin-contact sensors, such as skin patches and biosignal collectors. After use, they can naturally degrade, reducing electronic waste pollution. However, pure PHA has limited long-term stability under body temperature and sweat, requiring blending modifications to improve its hydrolysis resistance and creep resistance. Current research directions include blending PHA with TPU or chemically crosslinking PHA to balance its biodegradability and durability.

Other natural polymers such as chitosan possess inherent antibacterial properties and have been attempted to be coated on the inner side of watch straps to enhance antibacterial effects and skin friendliness. However, chitosan has poor water resistance and requires modification before use. With optimized formulations, bio-based materials have the full potential to meet the demanding usage environments of wearable electronic products.

Fossil has launched a limited-edition Solar Watch featuring a bio-plastic case made from castor oil and a strap crafted from recycled PET bottle fibers, achieving a combination of environmental protection and performance.

The application of bio-based polymers in products has moved from experimentation to the market, with some well-known brands and manufacturers taking the lead in making attempts.

Huawei: Huawei is one of the early manufacturers to use bio-based plastics in consumer electronics. From phone cases to smartwatch exterior components, Huawei has adopted partially bio-based polymers containing castor oil. By the end of 2020, Huawei had used a total of 1,223 tons of bio-based materials, which is equivalent to reducing carbon dioxide emissions by approximately 6,238 tons.

Realme has launched the world's first bio-based design back cover on the GT2 series phones, making the phone's back texture similar to paper and more environmentally friendly. The carbon emissions during the manufacturing process of the back cover material are reduced by about one-third compared to traditional plastics.

Swiss brand Mondaine has launched the Essence series watches, claimed to be the world's first watches featuring cases made from castor oil-based bioplastic. The case material is supplied by BASF, with castor oil biopolymer accounting for about 41%, complemented by natural glass fiber reinforcement, enabling the watch to achieve conventional resin case standards in impact resistance and water resistance.

Swatch Group uses "bioceramic" material in some of its products — a blend of two-thirds ceramic powder and one-third castor oil-based plastic, combining the hardness of ceramic with the toughness of bioplastic.

The fashion brand Diesel has also launched some bio-based watches, with watch cases containing about 45% castor oil-based plastic and equipped with solar-powered movements.

With the maturity of technology and large-scale production, bio-based materials will see broader application in the smart wearable industry. They not only respond to the trend of environmental sustainability but also provide new ideas for enhancing product added value and creating a healthy and user-friendly experience.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track