Case Study | Clariant AddWorks™ Additives Solve Plastic Yellowing Problem

Case Study

"This storage box looks old?" — A brand-new transparent food container appears "worn out before being sold" due to its yellowed surface, leading consumers to mistakenly believe it is old stock. This is not only a flaw in appearance but also a critical factor affecting market competitiveness.

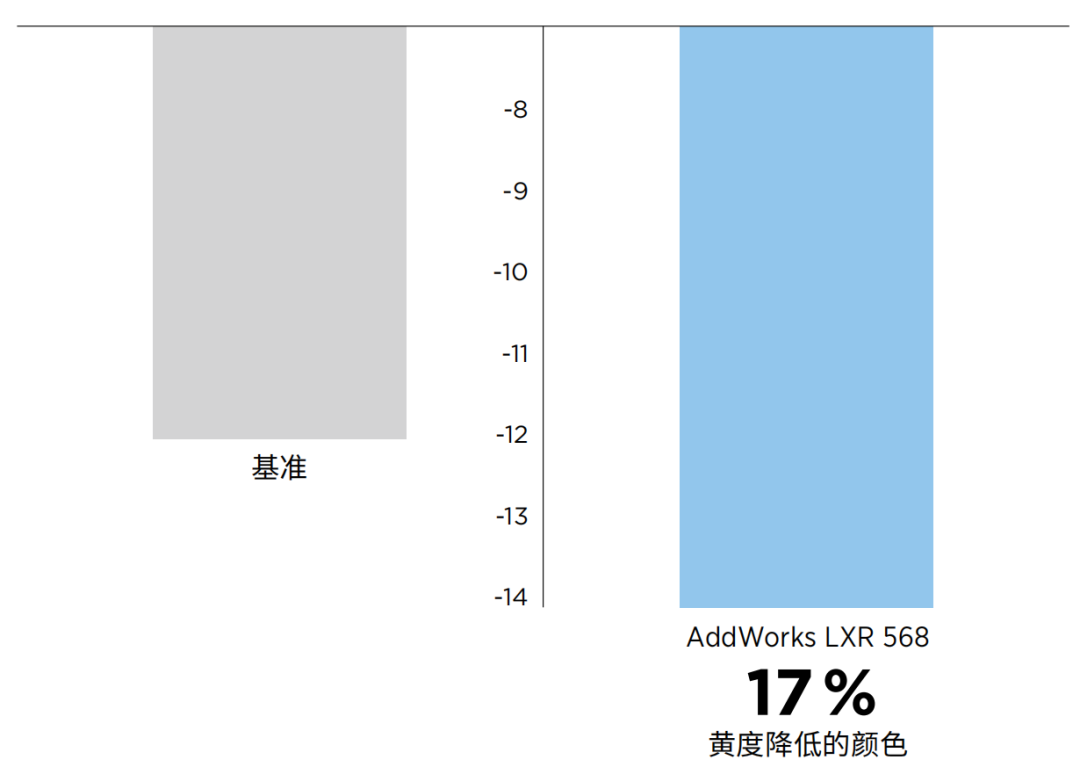

When our clients urgently need to solve the problem of #plastic yellowing,Clariant AddWorks™ LXR 568 High-Performance StabilizerLike a "magic potion," it helps clients.The degree of yellowing is reduced by 17%.The improvement results have restored the translucent color of plastic products.

Next, let's explore together.The Secret to the Success of AddWorks™ LXR 568

How to solve the problem of plastic yellowing?

When the customer used a peroxide viscosity-reducing random copolymer in their high-speed short-cycle injection molding process, despite the resin's superior performance in other aspects, the excessive discoloration throughout the molding process resulted in the final material exhibiting an excessively high yellowness index (YI).

The client needs a high-quality resin that can overcome yellowing defects and maintain the same quality level, enabling high-speed injection molding in a short cycle to ultimately produce packaging products with a transparent appearance and an attractive pure white color.

Clariant AddWorks™ LXR 568

High-performance stabilizer

Efficient whitening, convenient to use.

Clariant AddWorks™ LXR 568# High Performance StabilizerProvided in a free-flowing, dust-free micro-pellet form, easy to handle.Compared to traditional additive solutions, AddWorks™ LXR 568 is a product that canImproving the yellowing phenomenon of LLDPE, BOPP, and CPP films.The ideal solution. Excellent color stability、Excellent melt flow rate (MFR) stability Excellent oven aging performance。

The customer only needs toReplace some of the antioxidants with AddWorks™ LXR 568.Easily add to the selected resin and use in the intended process to significantly reduce the discoloration of materials during molding, and the final material's yellowing degree is less than before.Reduced by 17%Just the right shade of white is presented.Improved the appeal and marketability of the final material.。

Significantly improve the yellowness index

At the same time,AddWorks™ LXR 568 demonstrates significantly superior hydrolysis resistance compared to dedicated phosphite esters....and will not hydrolyze in ambient humidity...Reduce the occurrence of black spots.In addition, it can feed better under humid conditions and delay the formation of non-intentionally added substances (NIAS).

According to the principles of use and regulations for additives, AddWorks™ LXR 568 complies with the requirements of GB 9685-2016 for use in most thermoplastic polymers, especially.Polyethylene, polypropylene, polycarbonate, polystyrene, PEI, and PPE.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track