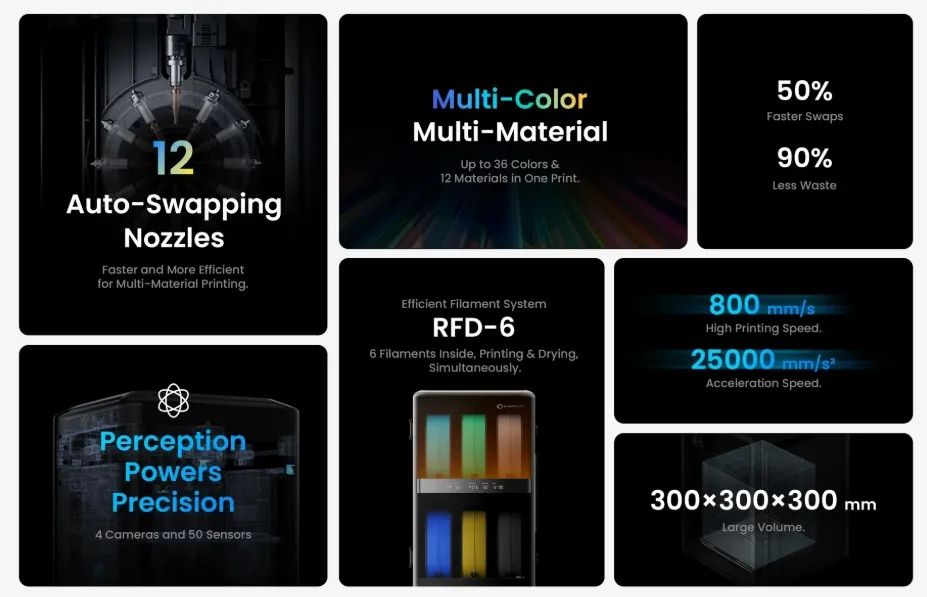

Raised Tens of Millions in Six Months, Launches 12-Nozzle 36-Color FDM 3D Printer

Currently, most multi-color FDM 3D printers on the market have only one print head. When printing colored models, it is necessary to switch between different colored filaments. During the filament changing process, a lot of material is wasted—sometimes several times the amount of filament is consumed just to print a single colored model.

Therefore, many 3D printing manufacturers are now developing new multi-nozzle solutions. Previously reported examples include WonderMaker's 4-nozzle solution, Bondtech's 10-nozzle solution, Snapmaker's 4-nozzle solution, and Inner Mongolia Zhonghe's spherical nozzle solution.

△Multicolor portrait model previously printed by Nanjixiong

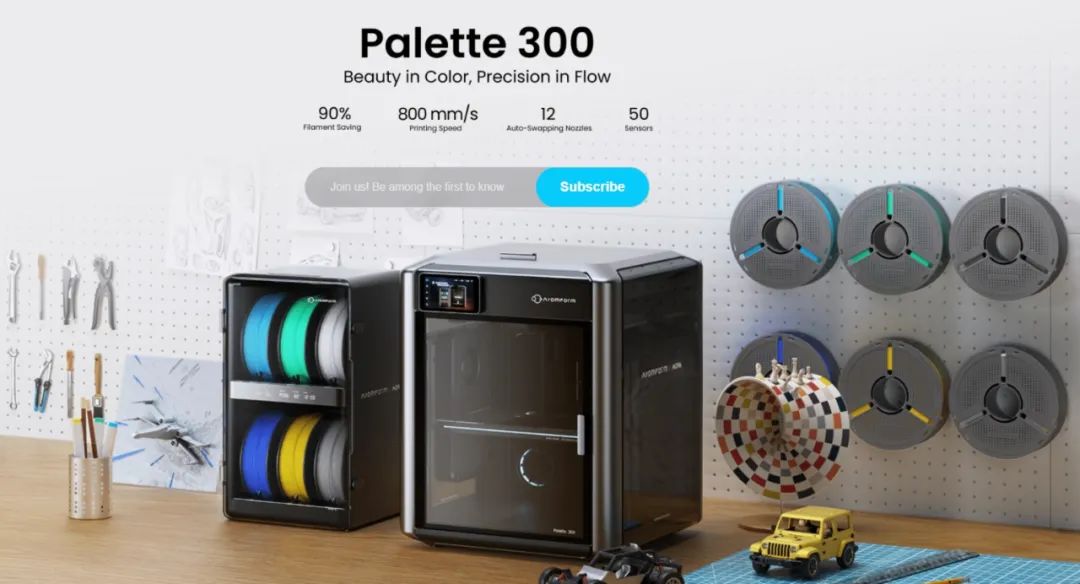

On August 11, 2025, it was learned from Antarctic Bear that a consumer-grade 3D printing startup, Atom Reshape, which was founded this year, announced its first 12-nozzle intelligent multi-color FDM 3D printer, the Palette 300, on its official website. In terms of specifications, this device appears to be quite competitive, but the price has not been disclosed yet.

12 nozzles automatic switching, maximum speed 800mm/s

From the information released on the official website, this 3D printer is equipped with a 12-nozzle intelligent switching system, supports fully automatic multi-color/multi-material printing, increases the printing speed to 800mm/s, and optimizes the extrusion structure design, reducing material waste by 90%.The Palette 300 features a unique OmniElement automatic nozzle switching function, allowing for up to 36 colors or 12 materials in a single print. This system increases material switching speed by 50%, providing a faster multi-color/multi-material switching experience. At the same time, through intelligent extrusion control, material waste is reduced by 90%, significantly lowering printing costs.

△Atomic Reshaping Palette 300 Intelligent Nozzle Principle Diagram

Additionally, the ReadyPrint™ dual-channel feeding system achieves multi-material composite printing through automatic nozzle switching and an intelligent preloading mechanism. The dual feeding system greatly improves the filament feeding process. It enables the newly prepared filament during each material change to be used directly, thereby significantly shortening the path and accelerating the switching process.

△ReadyPrint™ Dual-Channel Feed System

Supports the connection of 6 material management systems in series, enabling printing with up to 36 colors.

Palette 300, through its advanced modular design, supports one-time printing of complex parts composed of multiple materials. Its innovative RFD-6 material management system can connect up to 6 units in series, enabling seamless switching among 36 colors, delivering an industrial-grade, colorful, and high-precision printing experience.

According to the official introduction, the advantages demonstrated by the device in performance testing include:

● Material Compatibility: Supports 7 types of engineering materials including PAHT (high-temperature nylon), TPU (flexible material), PA (nylon), PETG, PLA, PC, and ABS, meeting the full range of application needs from flexible parts to structural components.

Efficiency breakthrough: In PAHT material printing, it takes only 6 hours and 55 minutes to complete the workload that other devices require 27 hours and 44 minutes for, achieving nearly a fourfold increase in efficiency.

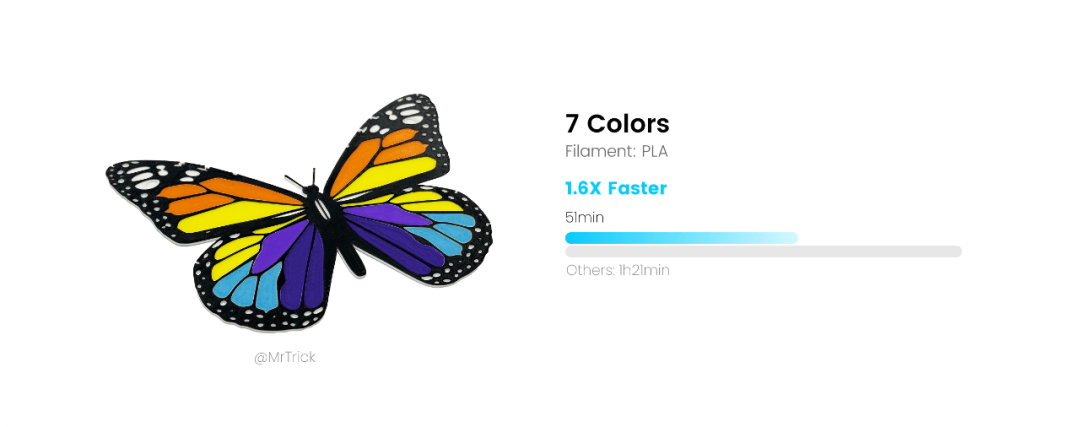

Color Printing Optimization: When using PLA material for 7-color printing, it only takes 51 minutes to complete a task that traditionally takes 1 hour and 21 minutes, achieving a 1.6 times speed increase.

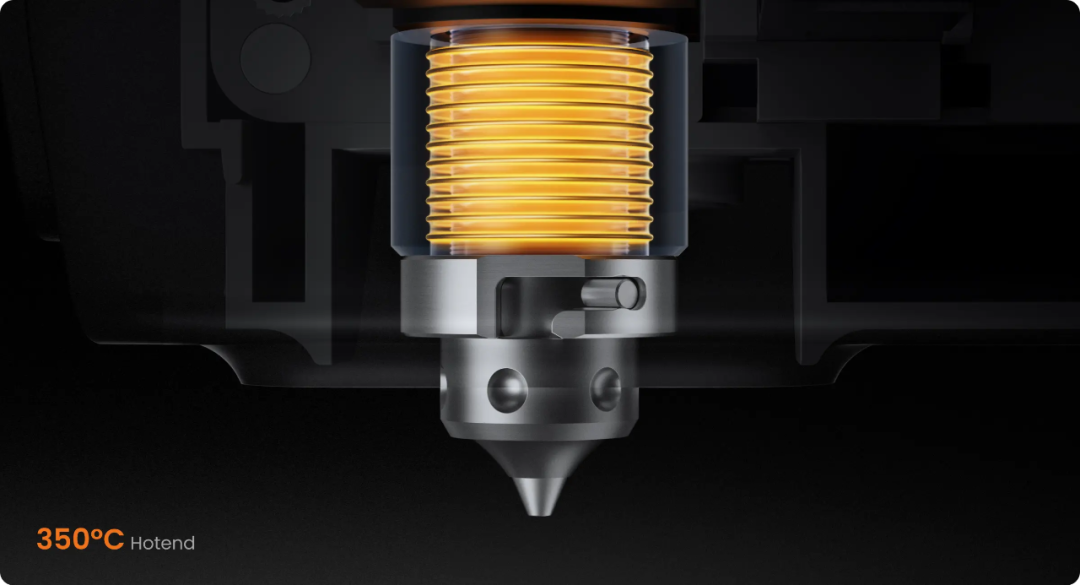

350℃ high-temperature head, intelligent printing platform

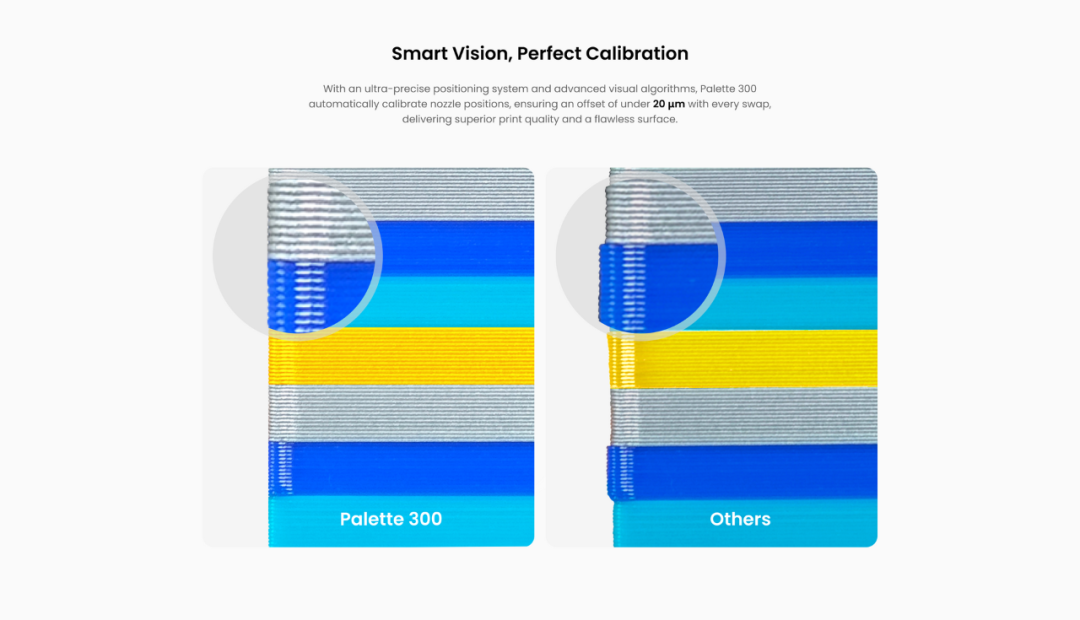

With an ultra-precise positioning system and advanced vision algorithms, the Palette300 can automatically calibrate the nozzle position, ensuring that the offset is less than 20 microns with each switch, thus providing better print quality and surface finish.

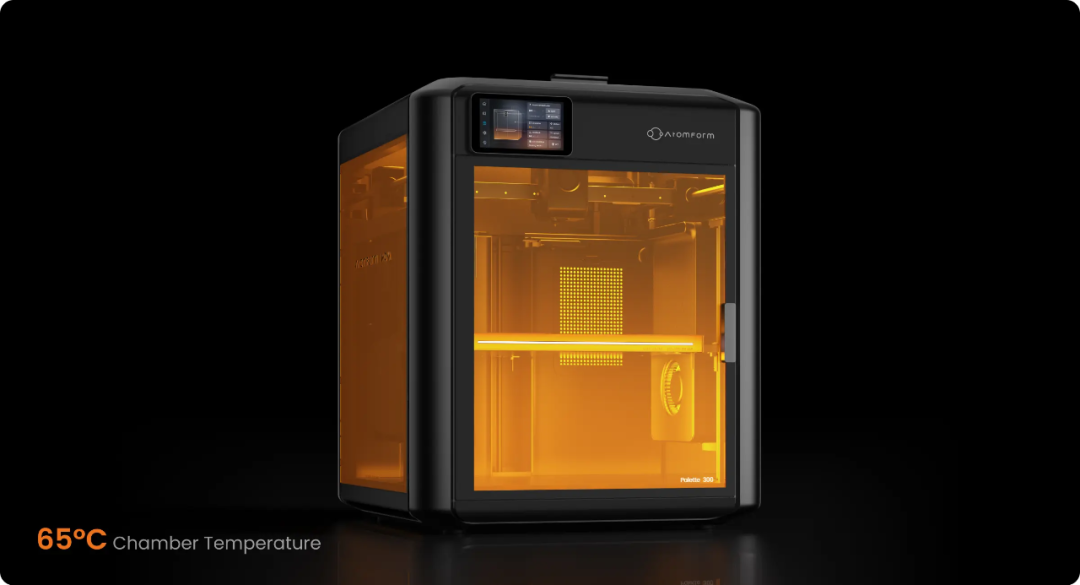

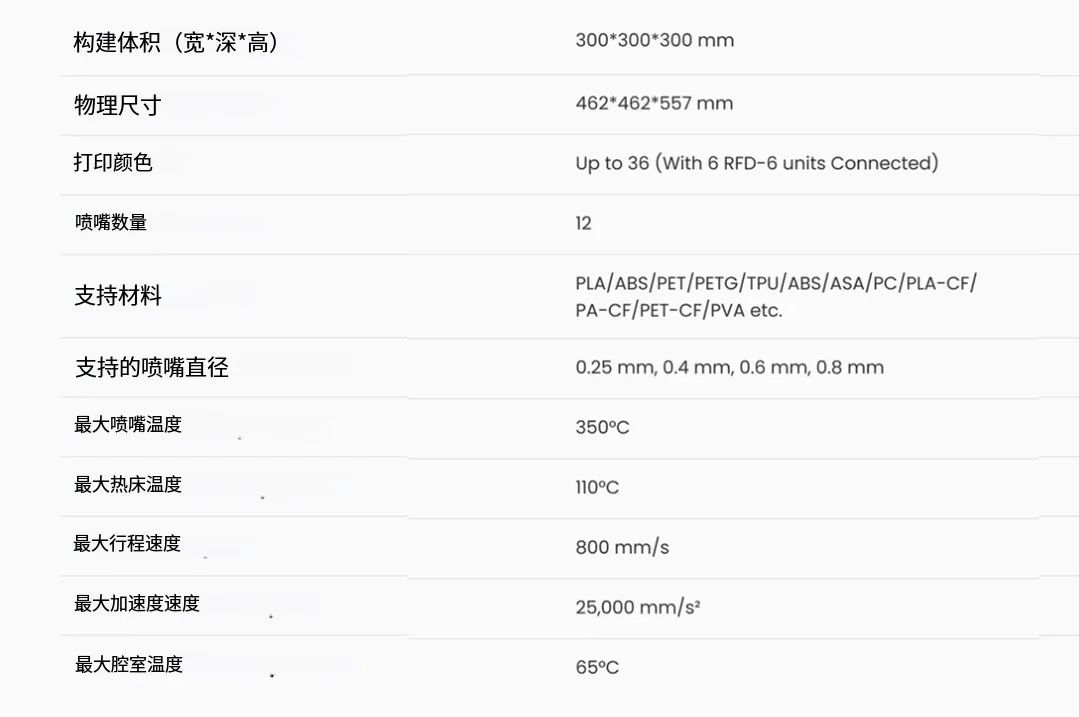

The Palette 300 features a build volume of 300x300x300mm, specifically designed for larger high-performance materials. The system's thermal management includes an active chamber heated up to 65°C and a hotend reaching 350°C, significantly reducing warping and ensuring strong adhesion and precision. Additionally, the hardened extruder and nozzle provide excellent durability and wear resistance, enabling stable, long-term printing of high-performance fiber-reinforced materials.

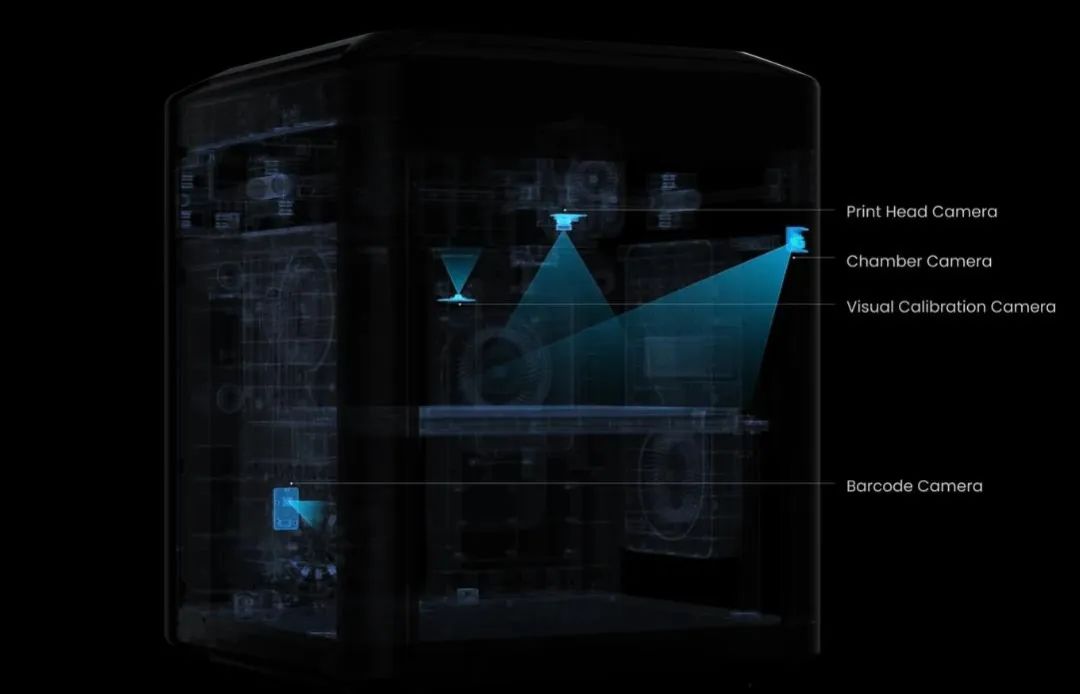

Additionally, equipped with 50 sensors and 4 cameras, the Palette 300 ensures that the printing results remain consistent with the design intent. The integrated barcode recognition camera can automatically identify different filaments, while the dedicated print head camera intelligently monitors material accumulation, filament deviation, and any faults during the extrusion process. Furthermore, a chamber camera for inspecting waste performs a thorough check before each print to guarantee perfect results every time.

Device Parameters

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track