R Plus Japan and Anelotech Partner to Advance Plas-TCat Technology Commercialization

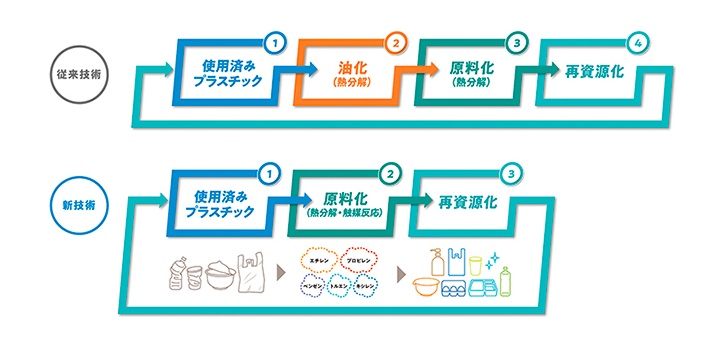

Recently, R Plus Japan (Rpy) and Anellotech jointly announced that their innovative catalytic pyrolysis technology, Plas-TCat, has officially entered the commercialization stage. This significant development is expected to reshape the landscape of chemical recycling and accelerate the implementation of circular economy solutions. The technology can directly convert mixed plastic waste into the basic chemicals needed to produce new plastics, providing a novel approach to addressing the issue of plastic pollution.

Before entering the commercialization phase, Plas-TCat technology underwent a rigorous and successful validation period. At Anelotech's TCat-8 semi-commercial facility in Silsbee, Texas, with a capacity of 200,000 kg per year, the technology was continuously operated for over 2,000 hours, demonstrating exceptional performance. This long-term test fully validated the technology's operational stability, scalability, and continuous online operational capability in real-world conditions.

A key milestone in advancing this commercialization process was the completion of the development of an independent Plas-TCat process design package. This achievement was made possible with technical support from Technip Energies and represents a significant breakthrough since Rpy and Anelotech launched their joint development project in 2020, highlighting the formidable power of international cooperation in tackling complex global challenges.

Atsushi Ohtake, CEO of R Plus Japan, stated: “Together with Anellotech, we have demonstrated our ability to provide next-generation, scalable solutions that truly advance plastic waste recycling. This milestone highlights the importance of international collaboration in addressing global sustainability challenges. We are delighted to be among the first to commercialize this technology in Japan and worldwide.” His remarks underscore the transformative potential of Plas-TCat technology and the firm commitment of both parties to making a substantial contribution to environmental sustainability.

In plant trials, the unique advantages of the Plas-TCat technology have been fully validated. Unlike traditional recycling methods, this technology employs a proven catalytic system that can convert unsorted and untreated mixed plastic waste—including a variety of materials such as PE, PP, PET, PS, PU, PC, ABS, and nylon—into high-value light olefins and aromatics. These products include key basic feedstocks such as benzene, toluene, xylene (BTX), ethylene, and propylene, as well as other valuable products, making significant contributions to the development of a circular economy. The two companies also stated that future plants may incorporate pretreatment units to handle halogen-containing feedstocks, further expanding the scope of the technology’s application.

With the comprehensive completion of technology validation, relevant parties are actively negotiating with potential raw material suppliers, product purchasers, and operational partners regarding the construction of a commercial plant. The Plas-TCat technology offers an attractive and cost-effective solution for plastic recycling, providing a new option for industries seeking sustainable development paths.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track